Carbon fluoride and application thereof

A technology of fluorinated carbon and carbon fluoride, which is applied in the field of materials, can solve problems such as low conductivity that have not been effectively solved, and achieve the effect of safe and controllable reaction, high working voltage platform, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Bamboo charcoal is crushed and washed with water, then the washed bamboo charcoal is dried, passed through a 200 mesh sieve, and the undersize is taken for subsequent use; 5.2g of the undersize is packed into an airtight container (the material of the airtight container is pure nickel or Monel alloy), and the Introduce NF in a closed container 3 gas and keep NF 3The pressure is 200KPa, heat the airtight container and keep the reaction temperature at 600°C, react for 1h; take out the product after natural cooling, vacuum treatment at 300°C for 4h to remove by-products in the fluorinated carbon, and obtain 11.4g of the fluorinated carbon product. The rate is 86%.

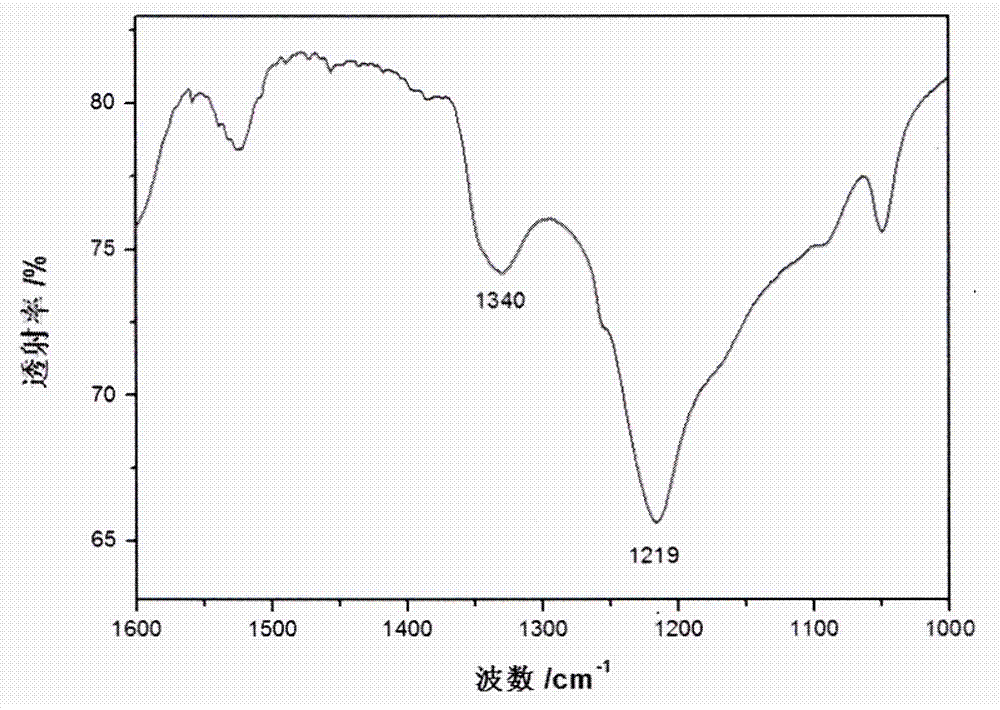

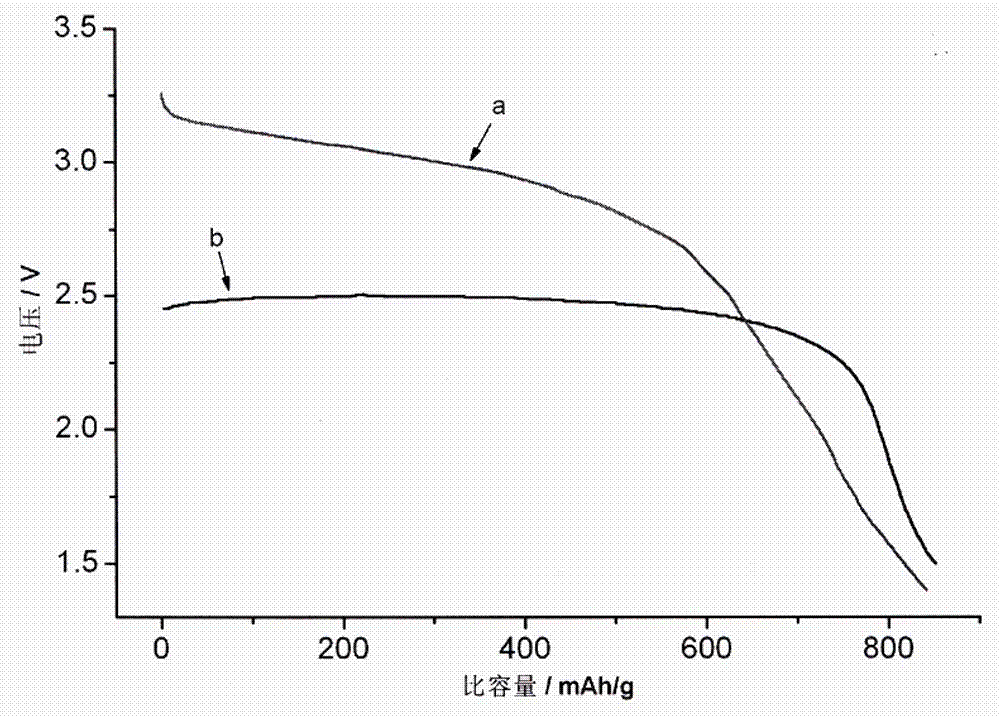

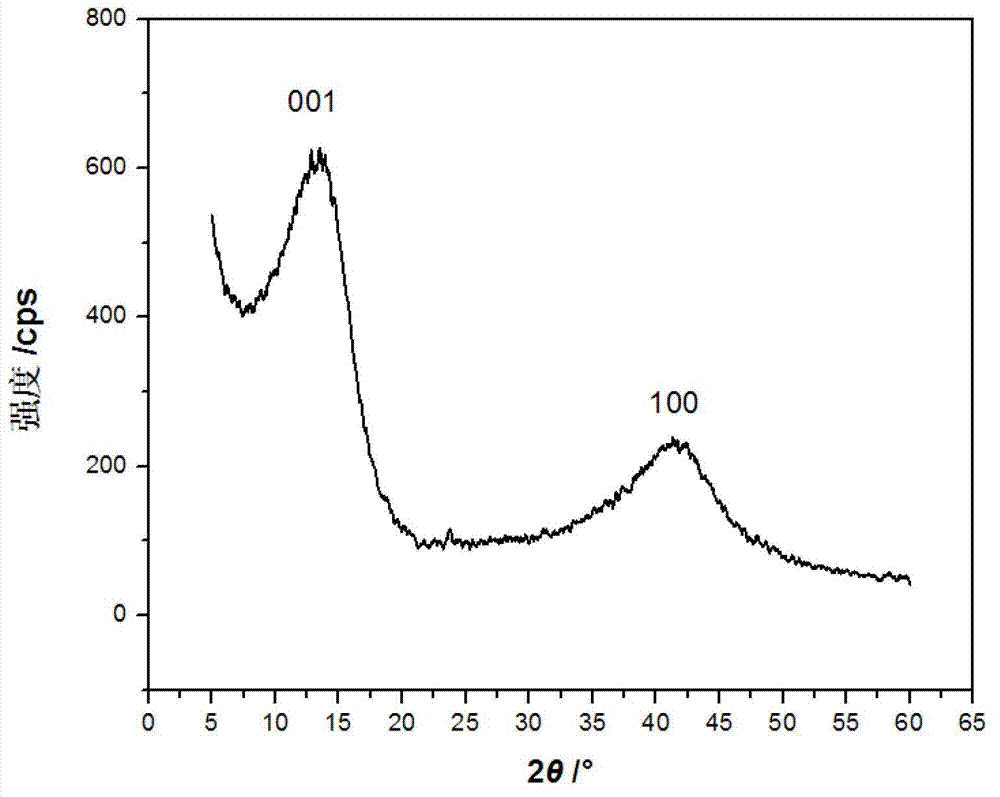

[0030] The carbon fluoride prepared in this example is analyzed by X-ray energy dispersive spectrometer (EDS), and the atomic ratio of fluorine to carbon is 1:1; in the infrared spectrogram ( figure 1 ), corresponding to the 1219cm of the C-F covalent bond -1 There is a strong absorption peak at ; by X-ray d...

Embodiment 2

[0032] Bamboo charcoal is crushed and washed with water, then the washed bamboo charcoal is dried, passed through a 200-mesh sieve, and the undersize is taken for subsequent use; 4.5g of the undersize is packed into an airtight container (the material of the airtight container is pure nickel or Monel alloy), and the Introduce NF in a closed container 3 gas and keep NF 3 The pressure is 500KPa, heat the airtight container and keep the reaction temperature at 450°C, react for 17h; take out the product after natural cooling, vacuum treatment at 200°C for 6h to remove the by-products in the fluorinated carbon, and obtain 10.3g of the fluorinated carbon product. The rate is 95%.

[0033] The carbon fluoride prepared in this example is analyzed by X-ray energy dispersive spectrometer (EDS), and the atomic ratio of fluorine to carbon is 0.90:1; analyzed by infrared spectrum, it corresponds to the 1219cm of C-F covalent bond -1 There is a strong absorption peak; after X-ray diffract...

Embodiment 3

[0035] Bamboo charcoal is crushed and washed with water, then the washed bamboo charcoal is dried, passed through a 200 mesh sieve, and the undersize is taken for subsequent use; 3.0g of the undersize is packed into an airtight container (the material of the heated part of the airtight container is pure nickel or Monel alloy , the rest of the parts are made of stainless steel), and the NF is passed into the airtight container 3 gas and keep NF 3 The pressure is 20KPa, heat the airtight container and keep the reaction temperature at 350°C, react for 20h; take out the product after natural cooling, vacuum treatment at 200°C for 6h to remove the by-products in the fluorinated carbon, and obtain 4.8g of the fluorinated carbon product. The rate is 88%.

[0036] The carbon fluoride prepared in this example is analyzed by X-ray energy scatter spectrometer (EDS), and the atomic ratio of fluorine to carbon is 0.2:1; analyzed by infrared spectrum, it corresponds to the 1219cm of C-F co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com