Technology and device for treating mixed waste water produced by cold-rolling pickling of stainless steel and carbon steel

A technology of pickling wastewater and treatment process, which is applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc., can solve problems such as difficult treatment, achieve convenient operation, reduce disposal costs, and reduce Effect of Environmental Burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

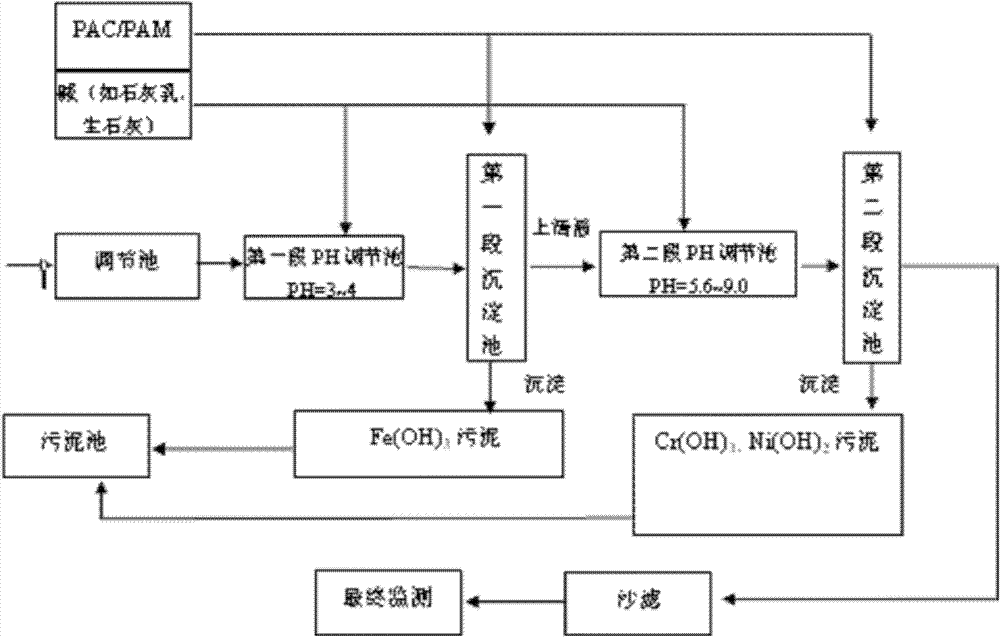

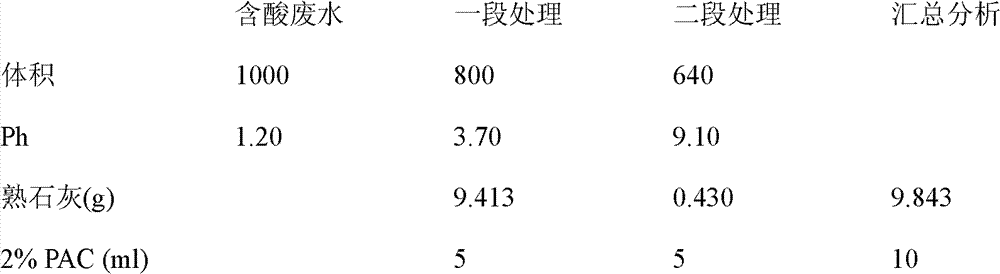

[0043] Select 1000ml of stainless steel and carbon steel cold rolling mixed wastewater, its chemical composition is mainly: iron ion 3631.58mg / L, chromium ion 225.34mg / L, nickel ion 38.54mg / L, pH value is 1.2. The chromium-containing wastewater is first reduced in the regulating tank, and the trivalent chromium-containing wastewater formed after the reduction of the hexavalent chromium effluent is mixed with the stainless steel carbon steel pickling wastewater into the regulating tank, and the mixed wastewater of the regulating tank enters the first stage of PH regulating tank through the lifting pump.

[0044] The treatment process is as follows: (1) Pass the wastewater through the first stage of PH adjustment tank, add 96% slaked lime to adjust the pH to 3.7 (96% slaked lime consumes 9.413g), and at the same time aerate the bottom of the tank, the aeration intensity is 1 hour per hour ~10m 3 (air) / m 3 (wastewater);

[0045] The effluent enters the first stage of sedimentat...

Embodiment 2

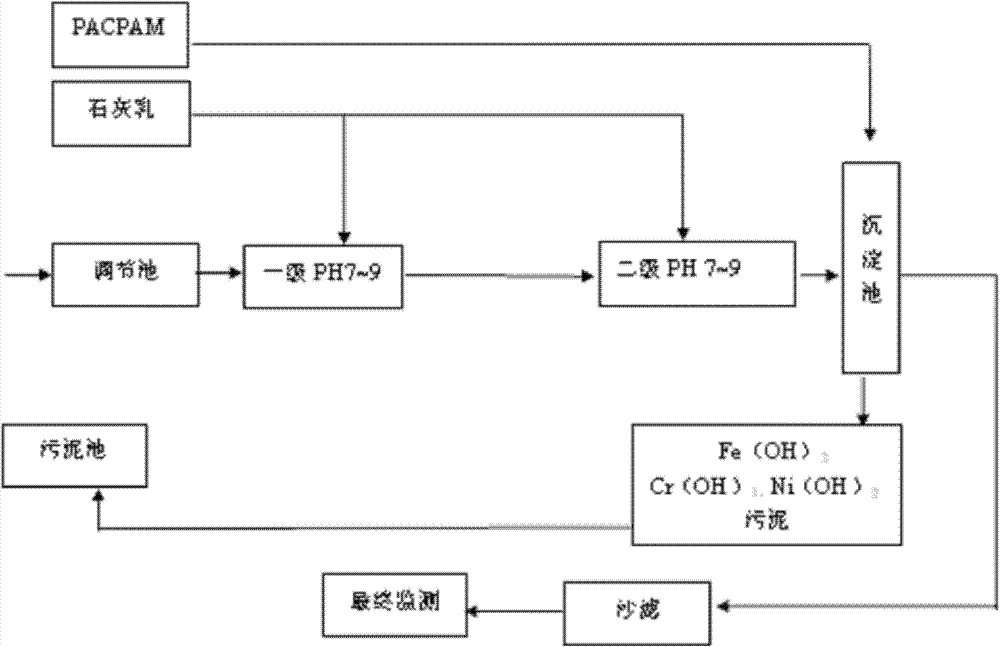

[0055] Select 1000ml of mixed wastewater from stainless steel and carbon steel cold rolling. Its chemical composition is mainly: iron ion: 1885.28mg / L, chromium ion: 213.70mg / L, nickel ion: 41.67mg / L, and the pH value is 1.2. It is first reduced in the adjustment tank, and the trivalent chromium-containing wastewater formed after the reduction of the hexavalent chromium effluent is mixed with the stainless steel carbon steel pickling wastewater into the adjustment tank, and the mixed wastewater in the adjustment tank enters a PH adjustment tank through the lift pump.

[0056] Treatment process: (1) Pass the wastewater through the first PH adjustment tank, add 96% slaked lime to adjust the pH to 4.68 (96% slaked lime consumes 9.92g), stir for 30 minutes, and at the same time aerate the bottom of the pool, the aeration intensity is hourly 1~10m 3 (air) / m 3 (wastewater);

[0057] The effluent enters the first stage of sedimentation tank, adding 5ml of 2% PAC and 1ml of 3‰PAM, a...

Embodiment 3

[0067] Select 1000ml of mixed wastewater from stainless steel and carbon steel cold rolling, its chemical composition is mainly iron ion 4014.12mg / L, chromium ion 173.97mg / L, nickel ion 20.31mg / L, pH value is 1.01. It is first reduced in the adjustment tank, and the trivalent chromium-containing wastewater formed after the reduction of the hexavalent chromium effluent is mixed with the stainless steel carbon steel pickling wastewater into the adjustment tank, and the mixed wastewater in the adjustment tank enters the first stage of PH adjustment tank through the lift pump.

[0068] Treatment process: (1) Pass the wastewater through the first PH adjustment tank, add 96% slaked lime to adjust the pH to 3.74 (96% slaked lime consumes 9.5181g), stir for 30 minutes, and aerate the bottom of the tank at the same time, the aeration intensity is hourly 1~10m 3 (air) / m 3 (waste water);

[0069] The effluent enters the first stage of sedimentation tank, add 5ml of 2% PAC and 1ml of 3‰...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com