Melting equipment and melting method for growing quartz crucible by thermal spraying

A quartz crucible, thermal spraying technology, applied in glass manufacturing equipment, manufacturing tools, glass molding and other directions, can solve the problems of crucible strength easily deformed, single wafer service life is not long, conversion rate is not up to standard, etc., to achieve good resistance. Devitrification performance, realization of smoothness and reliability, effect of improving crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

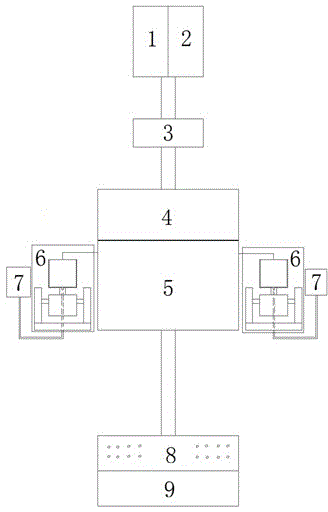

[0022] 1. First, turn on the switch cabinet 2 and the compensation cabinet 1 first, turn on the ion water cooling device 15 on the thermal spray molding device 6, and keep the circulating water pressure of the ion water at about 0.2Mpa, and keep it open. Operation console 9 sends electricity;

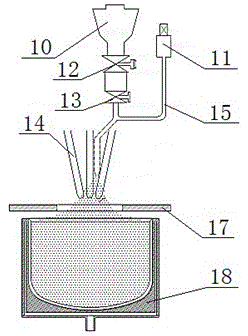

[0023] 2. Open the high and low cylinder oil level regulating valve on the vacuum pump 7 for 5 minutes, then close the vacuum pump 7 and the ion water cooling device 3, and adjust the position of the thermal spray heat shield 17 to 12mm from the upper opening of the water cooling jacket;

[0024] 3. Adjust the motor rotating device 11 so that the rotating speed is 85 rpm, adjust the arc welding transformer current of the cluster electrode rod 14 to 1400A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com