High-reliability and high-efficiency fluorescent glass for packaging LED (light emitting diode) and preparation method thereof

A technology of LED encapsulation and fluorescent glass, which is applied in electrical components, circuits, semiconductor devices, etc. It can solve the problems of difficult control of the mixed dispersion of phosphor powder and silica gel, uneven sedimentation of phosphor powder, light leakage, etc., and achieve process indicators that are easy to control , Easy to industrialized production, not easy to aging and failure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

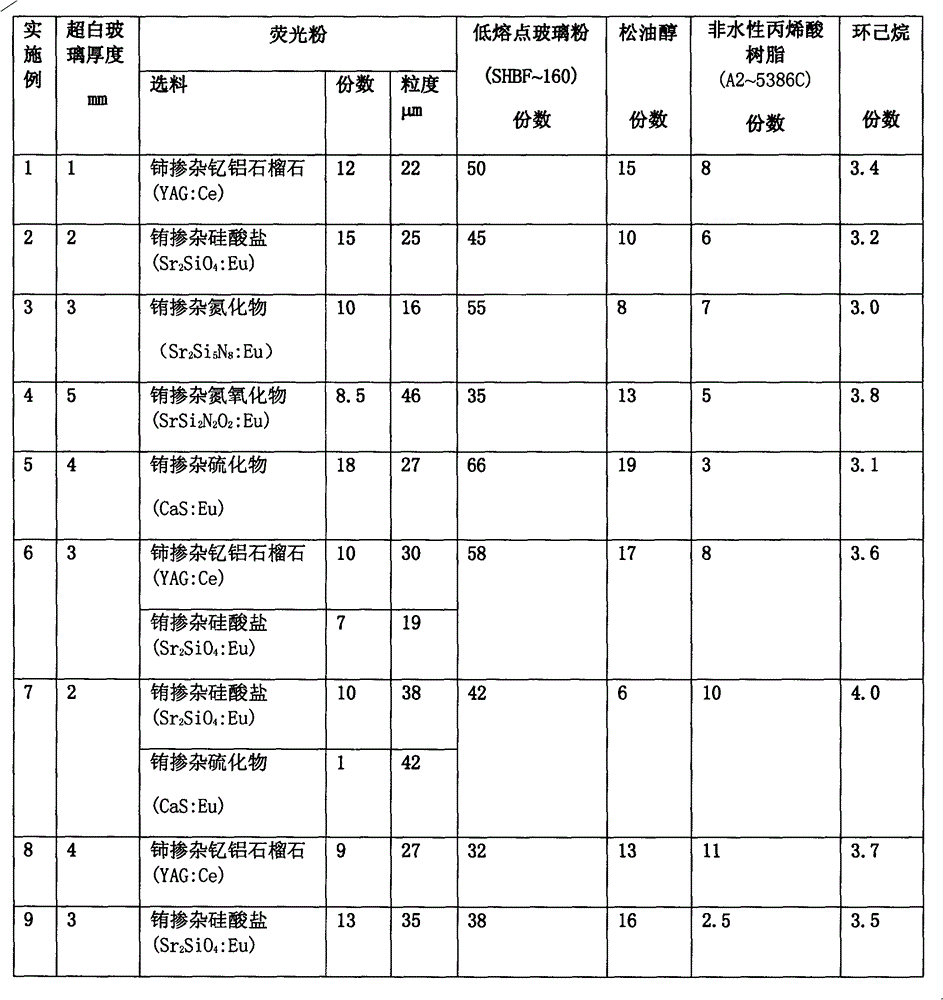

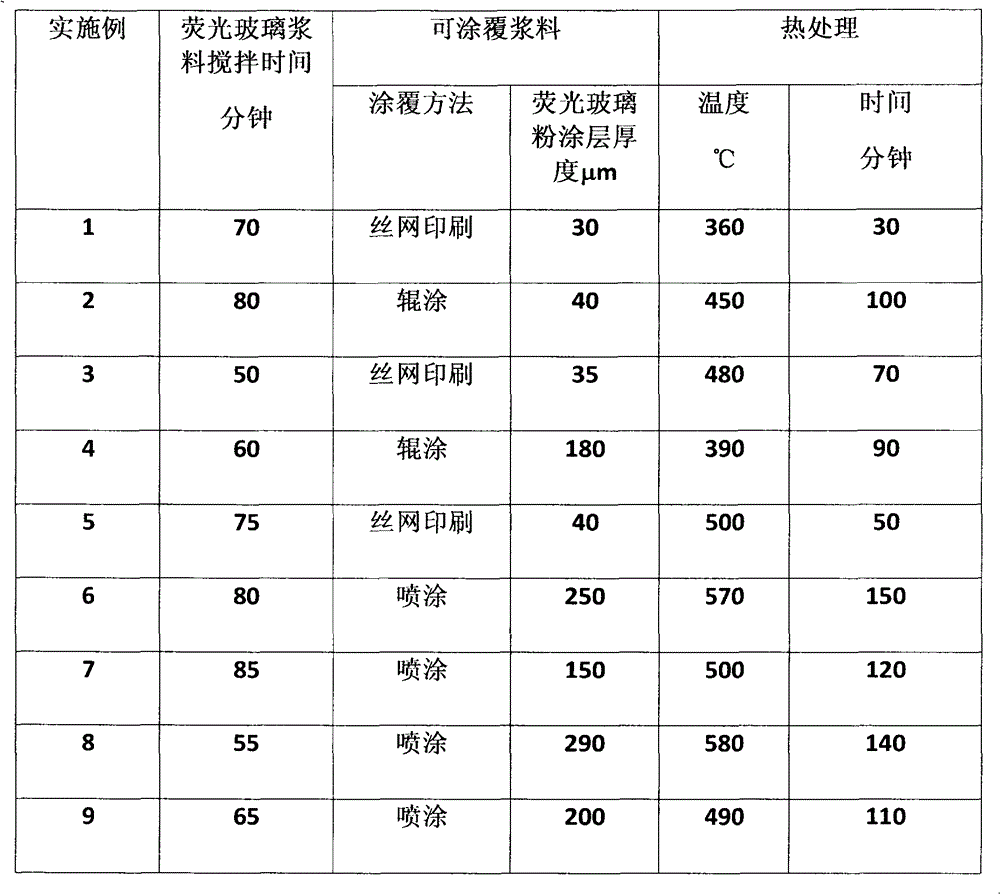

Examples

Embodiment 1

[0023] Using ordinary ultra-white glass with a thickness of 2mm as the substrate; 12 parts of cerium-doped yttrium aluminum garnet (YAG:Ce) with a particle size of 22 μm, 50 parts of low-melting glass powder, 15 parts of terpineol, and 8 parts of non-aqueous acrylic resin 3.4 parts of cyclohexane mixed together to obtain fluorescent glass powder slurry, the mixed fluorescent glass powder slurry was stirred at a speed of 300 to 350 rpm for 70 minutes to form a uniformly mixed slurry that can be coated. Afterwards, the coatable paste is printed on the surface of the ultra-clear glass substrate by screen printing method, and then placed in a high-temperature sintering furnace for heat treatment at 360°C for 30 minutes, and the fluorescent glass paste The material is solidified on the ultra-white glass substrate, and the thickness of the fluorescent glass powder coating is 30 μm, thereby obtaining the fluorescent glass for LED packaging.

[0024] After cutting the prepared fluores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com