Water-based additive composite

A technology of water-based additives and compositions, applied in the direction of adhesive additives, non-polymer adhesive additives, anti-corrosion coatings, etc., can solve the problem of freeze-thaw stability that cannot completely replace coatings, adverse effects of preparation and production, irritating odor, etc. problems, to achieve the effect of extending the construction time limit, ensuring health and low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

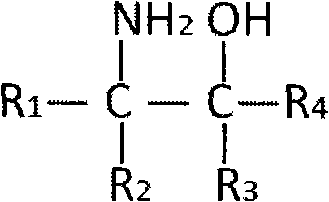

Method used

Image

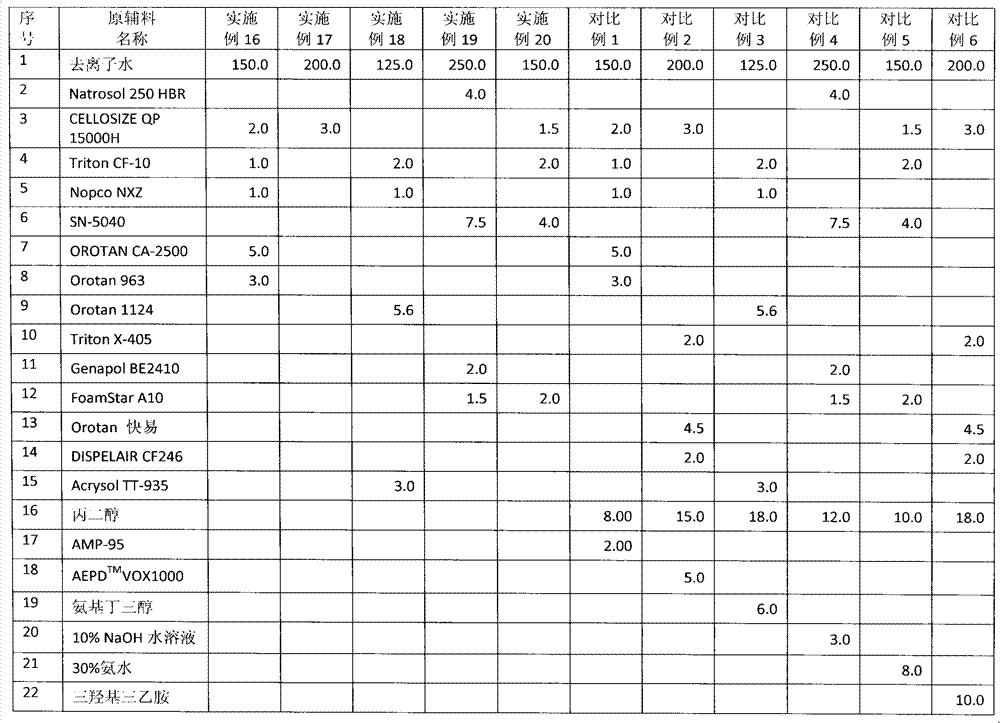

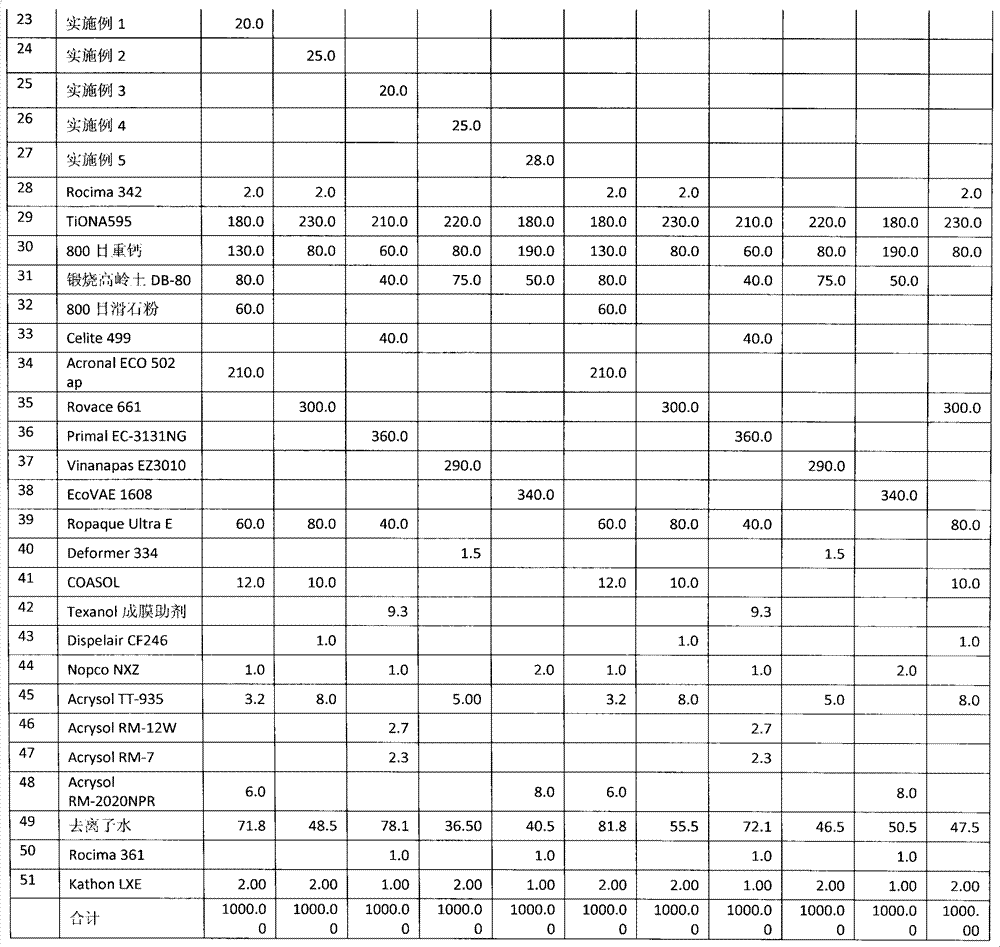

Examples

Embodiment 1

[0205] Process: At room temperature (usually 25°C), under stirring at an appropriate level (usually 200-1500 rpm), add deionized water, and then add tromethamine and bis(2-hydroxyethyl)amino (tri hydroxymethyl)methane, stirring continuously until completely dissolved, then adding AEPD TM Mix VOX1000 and trihydroxytriethylamine evenly to obtain the water-based additive composition of the present invention.

Embodiment 2

[0207] Process: under the condition of 30°C, under stirring at an appropriate level (usually 200-1500 rpm), add deionized water, then add 1,3-bis((trimethylol)methylamino)propane, and keep stirring Until it is completely dissolved, then add serinol, keep stirring until it is completely dissolved, then add threoninol, keep stirring until it is completely dissolved, then add aminobutanediol, keep stirring until it is completely dissolved, then add trihydroxytriethylamine, mix Evenly, the water-based additive composition of the present invention is obtained.

Embodiment 3

[0209] Process: under the condition of 35°C, under stirring at an appropriate level (usually 200-1500 rpm), add deionized water, then add 1,3-bis((trimethylol)methylamino)propane, and keep stirring Until it is completely dissolved, then add aminobutanediol, continue to stir until it is completely dissolved, then add trihydroxytriethylamine, and mix evenly to obtain the water-based additive composition of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com