Heat-resistant organic silicon red mark coating for railway vehicles

A rail vehicle, high temperature resistance technology, applied in the direction of coating, can solve the problems of poor alkali resistance, short shelf life, single color, etc., and achieve the effect of excellent high temperature resistance, long shelf life and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

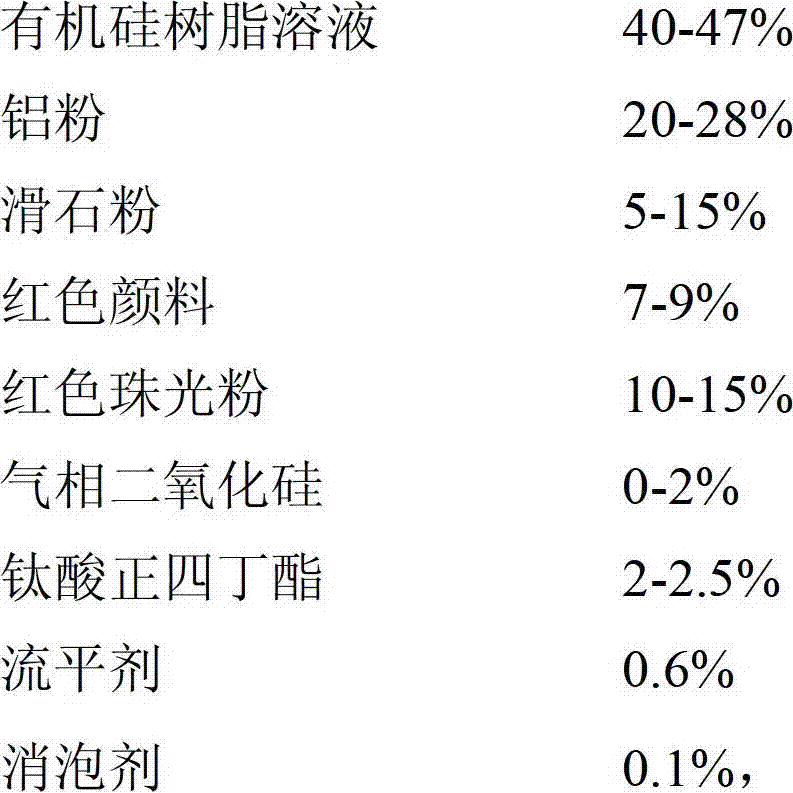

[0030]Prepare coatings according to the ratio given in Table 1. Mix the solid content of 70% methylphenyl silicone resin solution, fumed silica (10-30nm, Hangzhou Wanjing New Material Co., Ltd.), aluminum powder (17-19μm, Henan Yuanyang Aluminum Co., Ltd.), talcum powder (600 mesh, Haicheng Jinheng Magnesium Co., Ltd.), iron oxide red (Hunan Changsha Sanhuan superfine iron oxide red), pearl powder GL524 (5-25μm, Hangzhou Jintian Pearlescent Pigment Co., Ltd.), tetra-n-butyl titanate ( Shanghai Kefeng Chemical Reagent Co., Ltd.) defoamer E1 and leveling agent S43 (Shenzhen Haichuan Chemical Technology Co., Ltd.) were mixed at 1000 rpm to obtain the high temperature resistant silicone red marking paint for rail vehicles of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com