Novel aqua regia system ITO (indium tin oxide) etching solution and its preparation method

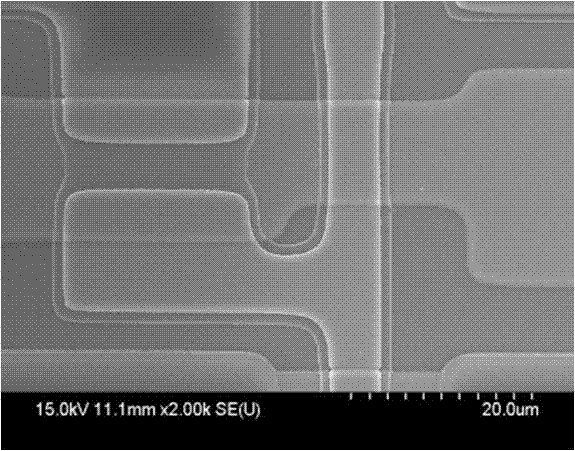

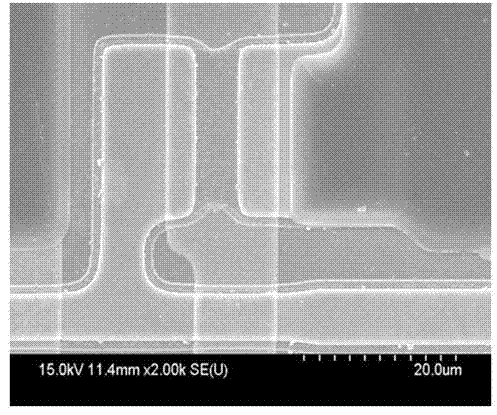

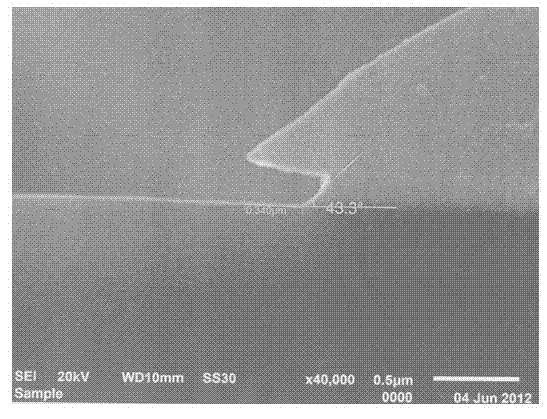

An etching solution and water system technology, applied in the field of new aqua regia ITO etching solution and preparation, can solve the problems affecting the image accuracy and quality of high-density thin wires, and achieve the effects of reducing side etching, no residue and stable reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The invention is a novel aqua regia-based ITO etching solution, which is uniformly mixed with six raw materials including hydrochloric acid, nitric acid, potassium chloride, potassium nitrate, surfactant and pure water.

[0034] Wherein, the weight percentages of the raw materials in the six can be respectively: 10 wt % hydrochloric acid, 1 wt % nitric acid, 0.1 wt % potassium nitrate, 0.1 wt % potassium chloride, 0.2 wt % sodium dodecylbenzenesulfonate, and the rest are Pure water; when the purity of raw materials changes, its ratio should be adjusted. Described hydrochloric acid, nitric acid concentration are respectively: nitric acid 61.5%. Hydrochloric acid 38%; The purity of potassium nitrate is higher than 99.5%, and the purity of potassium chloride is higher than 99.5%. The remaining impurity components in the potassium chloride and potassium nitrate raw materials are sodium chloride, water and a very small amount of impurities insoluble in the etching solution....

Embodiment 2

[0050] The invention is a novel aqua regia-based ITO etching solution, which is uniformly mixed with six raw materials including hydrochloric acid, nitric acid, potassium chloride, potassium nitrate, surfactant and pure water.

[0051] Wherein, the weight percentages of the raw materials in the six can be respectively: 30wt% hydrochloric acid, 10wt% nitric acid, 5wt% potassium nitrate, 5wt% potassium chloride, 3wt% alkylphenol polyoxyethylene ether, and the rest are pure water; After the purity of the raw material changes, its ratio should be adjusted. Described hydrochloric acid, nitric acid concentration are respectively: nitric acid 61.5%. Hydrochloric acid 38%; The purity of potassium nitrate is higher than 99.5%, and the purity of potassium chloride is higher than 99.5%. The remaining impurity components in the potassium chloride and potassium nitrate raw materials are sodium chloride, water and a very small amount of impurities insoluble in the etching solution.

[005...

Embodiment 3

[0061] The invention is a novel aqua regia-based ITO etching solution, which is uniformly mixed with six raw materials including hydrochloric acid, nitric acid, potassium chloride, potassium nitrate, surfactant and pure water.

[0062] Wherein, the weight percentages of the raw materials in the six can be respectively: 25wt% hydrochloric acid, 8wt% nitric acid, 3wt% potassium nitrate, 3wt% potassium chloride, 2wt% dodecylbenzenesulfonic acid, and all the other are pure water; After the purity of the raw material changes, its ratio should be adjusted. Described hydrochloric acid, nitric acid concentration are respectively: nitric acid 61.5%. Hydrochloric acid 38%; The purity of potassium nitrate is higher than 99.5%, and the purity of potassium chloride is higher than 99.5%. The remaining impurity components in the potassium chloride and potassium nitrate raw materials are sodium chloride, water and a very small amount of impurities insoluble in the etching solution.

[0063]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com