A high-generation flat copper-titanium film acid etching solution

An acid etchant and generation flat technology, applied in the field of high-generation flat copper-titanium film acid etchant, can solve the problems of unsatisfactory wiring cross-section shape, difficult control of reaction speed, slow initial etching rate, etc., and achieve good wiring cross-section shape, Effect of suppressing thermal decomposition and moderate etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

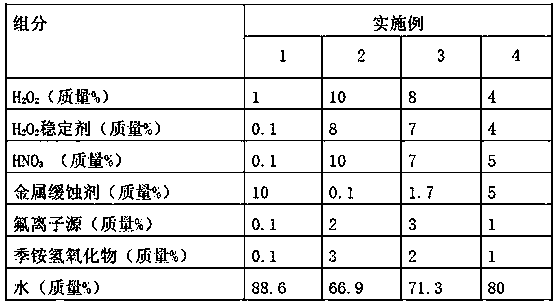

[0023] Configuration embodiment 1-4 etchant according to the contents listed in the table below:

[0024]

[0025] Among the components of Examples 1-4, the hydrogen peroxide all adopts commonly used phenylurea, and the metal corrosion inhibitors of 1-4 are all formed by recombining cyclic imine and 5-amino-1H-tetrazole; the fluoride ion source Using ammonium fluoride;

Embodiment 5

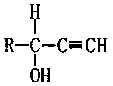

[0027] The corrosion inhibitor in embodiment 5 is formed by combining propynyl alcohol (R in the structural formula of alkyne alcohol is H) and 5-methyl-1H-benzotriazole, and the weight percentage of alkynyl alcohol in the corrosion inhibitor is 10 %;

Embodiment 6

[0028] In Example 6, the corrosion inhibitor is formed by combining butynol (R in the structural formula of acetylene alcohol is methyl) and 5-methyl-1H-benzotriazole, and the weight percentage of butynol in the corrosion inhibitor is 2 %; Fluoride ion source adopts ammonium bifluoride;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com