Method for extracting cellulose from tobacco waste based on reductant-oxidant

A technology of tobacco waste and cellulose, which is applied in fiber raw material processing, textile and papermaking, etc., can solve the problems of non-compliance with energy saving and emission reduction, corroded equipment, and high energy consumption, and achieves huge industrial production potential, low environmental pollution, and energy efficiency. low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

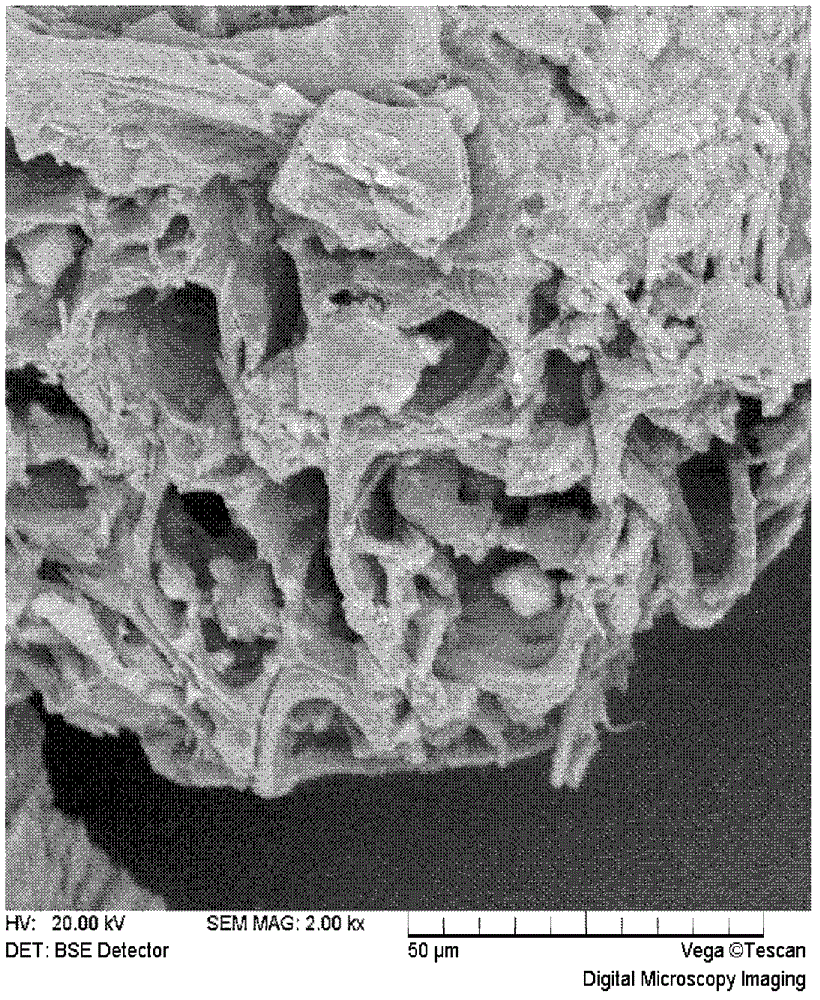

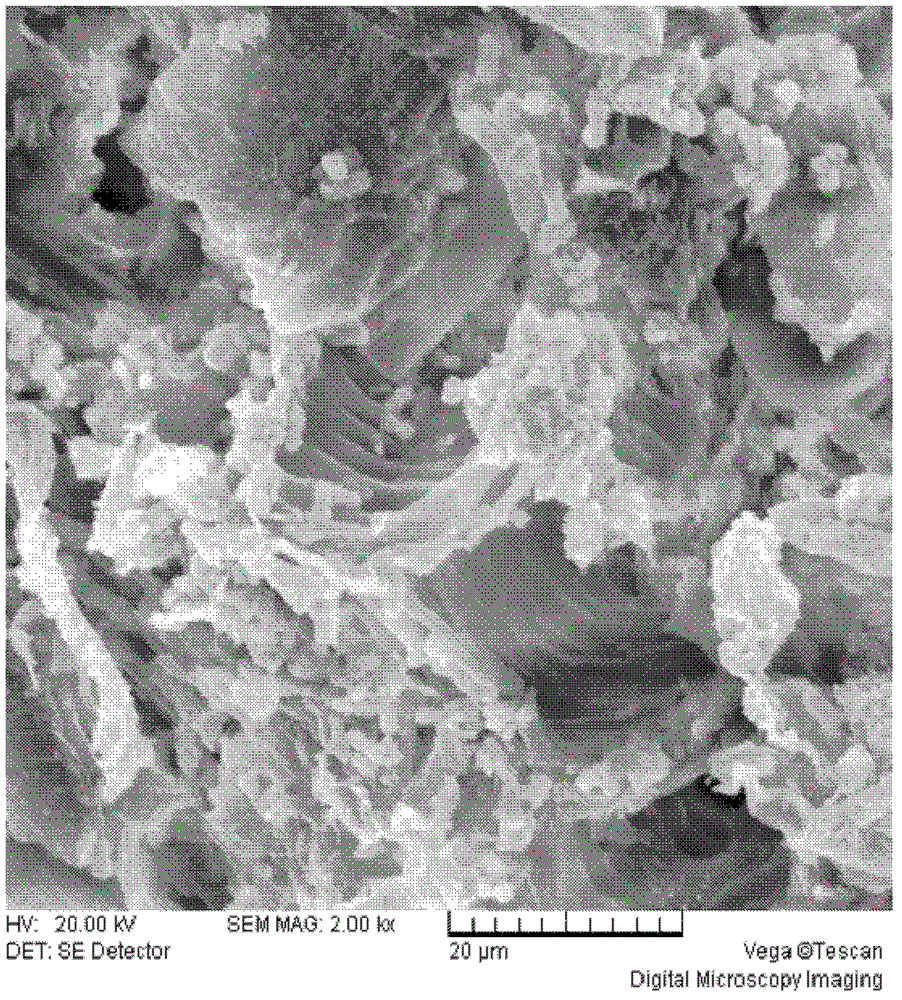

Image

Examples

Embodiment 1

[0024] Take 100g of tobacco waste with a particle size of 20 meshes, boil it in water for 1 hour, then separate the solid from the liquid, take the solid, add 60% ethanol with a volume percentage equivalent to 20 times the volume of the solid, and heat it at 100°C Stirring for 2 hours, the reaction solution was filtered, and the obtained filter residue was moved into an oven, and dried at 105° C. until the mass was constant to 39.1 g, and the cellulose content in the filter residue was 34%.

Embodiment 2

[0026] Accurately weigh 170 g of NaOH and dissolve it in 510 mL of distilled water to prepare a NaOH solution with a concentration of 25% by mass. Weigh 100g of tobacco waste with a particle size of 20 mesh and put it into a three-necked bottle, then add 500mL of NaOH solution with a mass percentage concentration of 25%, and react with mechanical stirring for 1 hour. After the reaction, wash and filter with distilled water until the filtrate Until it is neutral, the obtained filter residue is moved into an oven and dried at 105° C. to a constant mass of 49.1 g after drying. The cellulose content in the filter residue only accounts for 65% of the total mass of cellulose.

Embodiment 3

[0028] Weigh 100g of tobacco waste with a particle size of 20 mesh and put it into a three-neck bottle, then add 500mL of hydrochloric acid solution with a mass concentration of 10%, and react with mechanical stirring for 1.5 hours. The resulting filter residue was moved into an oven and dried at 105°C to a constant mass of 48.7g after drying. The cellulose content in the filter residue only accounted for 67% of the total mass of cellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com