Dustproof pellicle film, manufacturing method thereof, and dustproof pellicle component with pellicle film attached

A dust-proof film assembly and dust-proof film technology, which are applied in the photomechanical process of photomechanical processing, pattern surface photoengraving process, optics, etc., to achieve a small reduction in film thickness, maintain exposure quality for a long time, and improve light resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

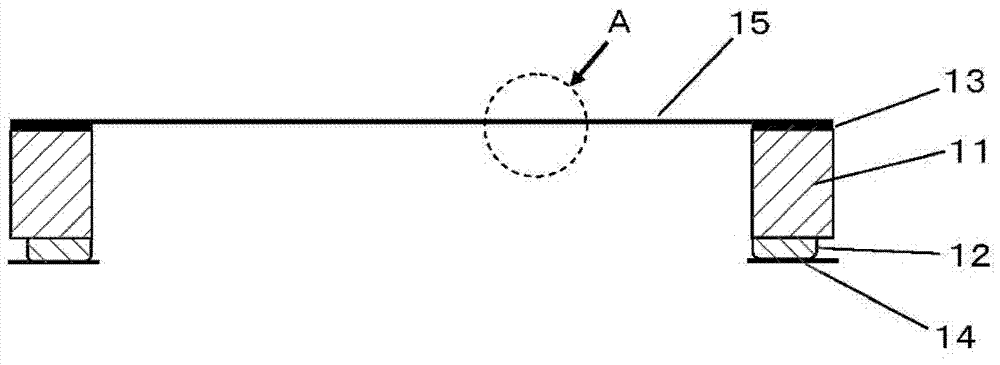

[0075] Such as Figure 4 The pellicle frame 41 made of A5052 aluminum alloy of the shape shown was produced by machining. The shape of the pellicle frame 41 is that the outer dimension of each corner is 1146 x 1392mm, the inner dimension is a rectangle of 1124 x 1370mm, and the thickness is 5.8mm. The shape of each corner is R2 inside and R6 outside. In addition, on the long side, four concave holes 43 with a diameter of 2.5 mm and a depth of 2 mm are provided for processing, and grooves 42 with a height of 2 mm and a depth of 3 mm are provided at two places on each of the short side and the long side. Further, on both long sides, 8 vent holes 46 with a diameter of 1.5 mm are provided.

[0076] The pellicle frame was transported into a class 10 clean room, washed well with a surfactant and pure water, and dried. Then, one end face of the pellicle frame is provided with a silicone adhesive layer as the pellicle adhesive layer 45, and the other end face is used as the photomas...

Embodiment 2

[0083] Same as Example 1, the outer dimension is 280×280, the inner dimension is 270×270, and the A5052 aluminum alloy dust-proof film assembly frame with a height of 4.8mm is made, and is carried out with surfactant and pure water in a clean room of class 10. Rinse well and dry completely. Thereafter, on one end face, a silicone adhesive (trade name: X-40-3004A, manufactured by Shin-Etsu Chemical Co., Ltd.) layer as an adhesive layer attached to a photomask was provided, and on the other end face, a As an adhesive for bonding the dustproof film, a silicone adhesive (trade name: KR3700, manufactured by Shin-Etsu Chemical Co., Ltd.) was applied and cured by heating in an oven. Then, a release sheet obtained by coating a 150-μm-thick PET film with fluorine-modified silicone was cut into a frame shape having almost the same outer dimension as the frame, and attached to the above-mentioned adhesive layer.

[0084] Then, on a quartz substrate of 350 x 350 x thickness 8 mm, which h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com