Composite porous electrode, single cell comprising composite porous electrode, cell stack and preparation method of composite porous electrode

A technology of porous electrodes and monomers, applied in battery electrodes, regenerative fuel cells, fuel cell groups, etc., can solve the problem of difficult balance between porosity and hardness of porous electrodes, so as to improve hardness and modulus and reduce contact resistance , The effect of low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

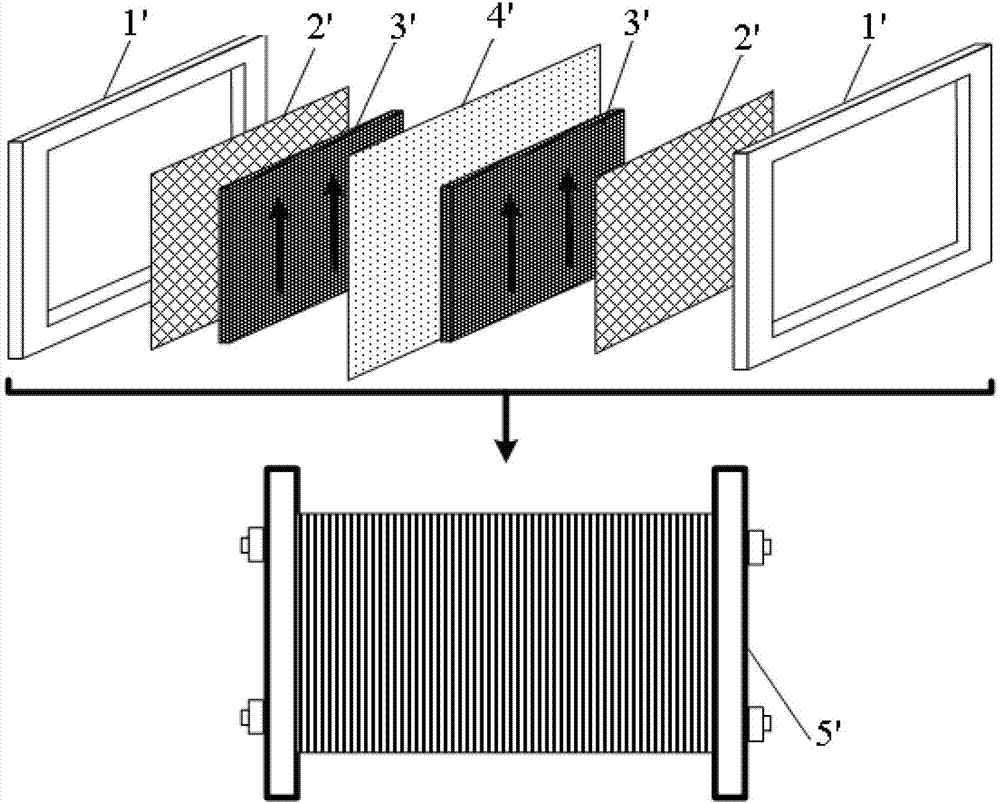

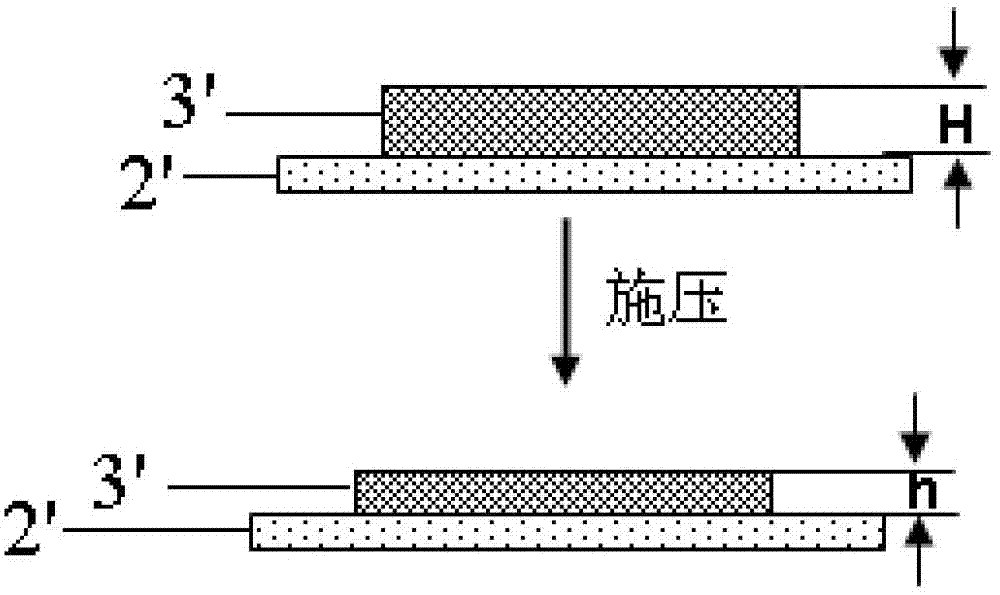

[0032] In a specific embodiment of the present invention, when the resin material is a thermoplastic resin composition, the preparation method includes the following steps: A1, dissolving the resin material in a solvent to form a resin with a mass concentration of the resin material of 0.5-20% Material solution; A2, immerse the porous electrode 3' in the resin material solution, so that the resin material solution is impregnated into the pores of the porous electrode body 3'; and A3, volatilize the solvent in the porous electrode body 3', and make the resin material adhere A resin layer was formed on the inner walls of the pores of the porous electrode body 3 ′ to obtain a composite porous electrode 3 .

[0033] Dissolving the resin material in its good solvent to form a resin material solution, and then immersing the porous electrode body 3' in the resin material solution, under the action of liquid pressure, the resin material is impregnated into the pores, and is heated or p...

Embodiment 1

[0044] Raw materials: Graphite felt is used as the porous electrode body with a porosity of 85% and an overall size of 36mm*36mm*8mm. Polystyrene is selected as the impregnating resin, and the solvent is dimethylformamide.

[0045] Preparation process: first dissolve polystyrene resin in dimethylformamide to form a solution with a mass concentration of 1%; then immerse graphite felt into the solution, and wait until the solution is evenly impregnated into the graphite felt, and slowly heat to 155 ℃, kept for 6 hours to gradually volatilize dimethylformamide; then slowly cooled to 25 ℃ to precipitate and solidify polystyrene, that is, a composite porous electrode in which graphite felt was impregnated with polystyrene resin as a whole, and the total weight of the resin layer was obtained 0.8% of the total weight of the composite porous electrode.

[0046] The single cell of Example 1 was obtained by assembling the current collecting plate, the liquid flow frame, the diaphragm ...

Embodiment 2

[0048] Raw materials: Graphite felt is used as the porous electrode body with a porosity of 85% and an overall size of 36mm*36mm*8mm. High-density polyethylene is selected as the impregnating resin, and the solvent is xylene.

[0049] Preparation process: first dissolve polyethylene resin in xylene to form a solution with a mass concentration of 8wt%; then immerse graphite felt into the solution, and wait until the solution is evenly impregnated into graphite felt, slowly heat to 50°C and keep for 6h The solvent is gradually completely volatilized; then slowly cooled to 25 ° C to precipitate and solidify the polyethylene resin, that is, a composite porous electrode with high-density polyethylene resin impregnated with graphite felt as a whole, and the total weight of the resin layer is 5% of the total weight of the obtained composite porous electrode. %.

[0050] The single cell of Example 2 was obtained by assembling the current collecting plate, the liquid flow frame, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com