Preparation method of probiotic solid-state fermented complete feed

A full-price feed, solid-state fermentation technology, applied in animal feed, animal feed, applications, etc., can solve the problems of decreased digestion and absorption rate of nutrients, destruction, and high cost of addition, and achieve improved digestion and absorption rate, high digestion and absorption rate, The effect of reducing the ratio of feed to meat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

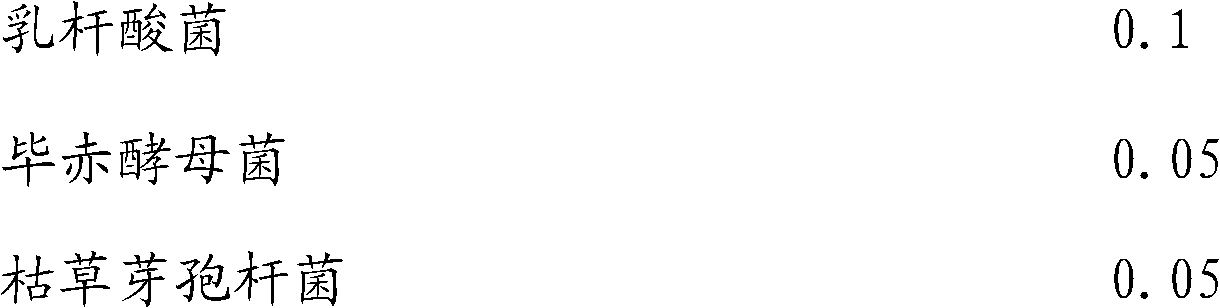

[0040] 1. Formula

[0041]

[0042]

[0043] All the above-mentioned raw materials can be purchased in the raw material market.

[0044] Second, the operation process steps are as follows:

[0045] (1) Mixing of ingredients: 46.7% of tap water, 0.3% of solid bacteria, 2% of neutral protease, and 1% of sucrose are dropped into the mixing container successively, and stirred until the sucrose is completely dissolved, and the bacteria and neutral protease are evenly dispersed in in water;

[0046] (2) Spray addition: the above-mentioned uniformly mixed mixed liquid is sprayed into 50% powdery full-price feed through liquid pump pressurized atomization, and mixed while spraying until the liquid is sprayed;

[0047] (3) Bagging fermentation: put the above-mentioned mixed material into a fermentation bag, tie the mouth after draining the air from the mouth of the bag, stack 4-6 layers, keep warm at 32-35 ° C, and perform solid-state fermentation for 4 days to obtain solid-sta...

Embodiment 2

[0051] 1. Formula

[0052]

[0053]

[0054] All the above-mentioned raw materials can be purchased in the raw material market.

[0055] Second, the operation process steps are as follows:

[0056] (1) Ingredients mixing: put 50.8% tap water, 0.2% solid bacteria, 3% neutral protease, and 1% sucrose in the mixing container in sequence, and stir until the sucrose is completely dissolved, and the bacteria and neutral protease are evenly dispersed in the water ;

[0057] (2) Spray addition: the above-mentioned uniformly mixed mixed liquid is sprayed into 45% powdery full-price feed through liquid pump pressurized atomization, and mixed while spraying until the liquid is sprayed;

[0058] (3) Bagging fermentation: put the above-mentioned mixed material into a fermentation bag, tie the mouth after draining the air in the mouth of the bag, stack 4-6 layers, keep warm at 32-35 ° C, and conduct solid-state fermentation for 7 days to obtain solid-state fermented feed.

[0059] ...

Embodiment 3

[0062] 1. Formula

[0063]

[0064]

[0065] All the above-mentioned raw materials can be purchased in the raw material market.

[0066] Second, the operation process steps are as follows:

[0067] (1) Ingredients mixing: put 47.7% tap water, 0.3% solid bacteria, 2.5% neutral protease, and 1.5% sucrose in the mixing container in sequence, and stir until the sucrose is completely dissolved, and the bacteria and neutral protease are evenly dispersed in the water ;

[0068] (2) Spray addition: spray the above-mentioned uniformly mixed mixed liquid into 48% powdery full-price feed through pressurized atomization by a liquid pump, and mix while spraying until the liquid is sprayed;

[0069] (3) Bagging fermentation: put the above-mentioned mixed material into a fermentation bag, tie the mouth after draining the air in the mouth of the bag, stack 4-6 layers, keep warm at 32-35°C, and conduct solid-state fermentation for 5 days to obtain solid-state fermented feed.

[0070] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com