Hydrogenation catalyst for sulfur-containing liquefied gas at low temperature, and preparation method and application thereof

A hydrogenation catalyst and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high hydrogenation temperature, long time, and tediousness , to achieve the effect of low hydrogenation reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Catalyst preparation: Weigh a certain amount of molded Y-alumina carrier, use soluble salt of nickel, soluble salt of cobalt, soluble salt of molybdenum to make a load solution equal to the volume of the carrier, and soak the carrier in the carrier at room temperature After a certain period of time in the loading solution, the remaining soaking solution is poured out, and after drying and roasting, the required catalyst is obtained. Contain Mo 2 o 3 8.0%~20.0%, NiO 6.0%~20.0%, CoO 1~3%, the prepared catalyst is Φ3×3~5mm strip type, or clover type, specific surface area 140~200m 2 / g.

[0040] Catalyst evaluation conditions: feed temperature 35~40℃, reaction temperature 40~100℃, reaction pressure 1.5~3.0MPa, volume liquid hourly space velocity 1.5~15.0h -1 , hydrogen / olefin molar ratio 1.1~1.4.

Embodiment 1

[0042] Take by weighing a certain amount of shaped Y-alumina carrier, according to the content Mo on the final catalyst 2 o 3 Content 12.0%, NiO content 10.0%, CoO content 1.0% Quantitatively weigh ammonium molybdate tetrahydrate, nickel nitrate hexahydrate, cobalt acetate tetrahydrate, make a solution equal to the volume of the carrier, and put the Y-alumina carrier at room temperature Soak in the solution for 12 hours, pour out the remaining soaking liquid. After drying at 125°C, it was divided into three parts and fired at 350, 375°C, 400°C, and 450°C for 6 hours. The prepared catalysts are 1#, 2#, 3#, 4#, and the specific surface area is 145.2m 2 / g, 159.8m 2 / g, 176.2m 2 / g, 198.5m 2 / g.

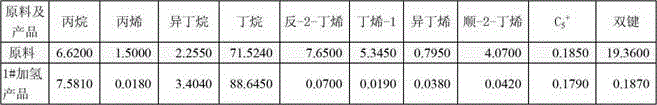

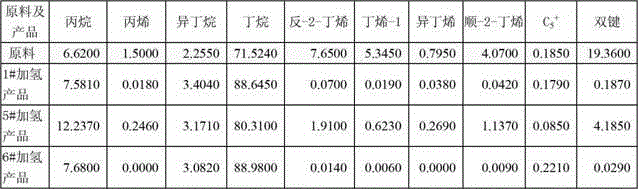

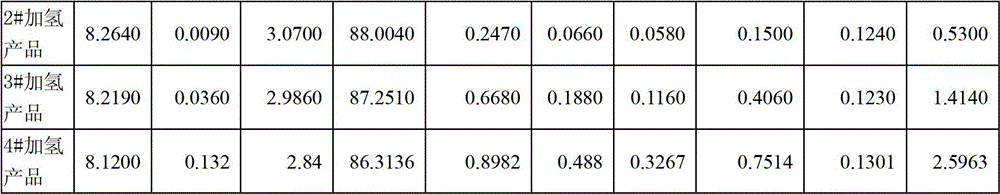

[0043] The prepared 1#, 2#, 3# catalysts were evaluated, the feed temperature was 35°C, and the reaction temperature was 40-65°C. The evaluation results are shown in Table 1.

[0044] Table 1 Hydrogenation performance of catalysts prepared at different calcination temperatures

...

Embodiment 2

[0049] Take a certain amount of shaped Y-alumina carrier, weigh nickel nitrate hexahydrate and cobalt acetate tetrahydrate according to the final catalyst with NiO content of 20.0% and CoO content of 3.0%, and make a solution with the same volume as the carrier. Soak the carrier in the solution for 12 hours, pour out the remaining soaking solution, and dry it at 120°C; 2 o 3 Content 20.0% Weigh ammonium molybdate tetrahydrate and make a solution with the same volume as the carrier. Soak the carrier loaded with nickel / cobalt in the solution for 12 hours at room temperature, pour out the remaining soaking solution, and dry at 120°C , 350 ℃ roasting 6h. The prepared catalyst is 5# with a specific surface area of 151.6m 2 / g.

[0050] The 5# catalyst was evaluated, the feed temperature was 35°C, and the reaction temperature was 40-65°C. The evaluation results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com