Solar catalytic oxidation-membrane separation three-phase fluidized bed circulation reaction device

A three-phase fluidized bed, photocatalytic reaction technology, applied in the field of solar photocatalytic oxidation-membrane separation three-phase fluidized bed circulating reaction device, can solve the problems of large catalyst influence, catalyst poisoning, small Reynolds number, etc. The effect of large wastewater treatment capacity, convenient operation and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation.

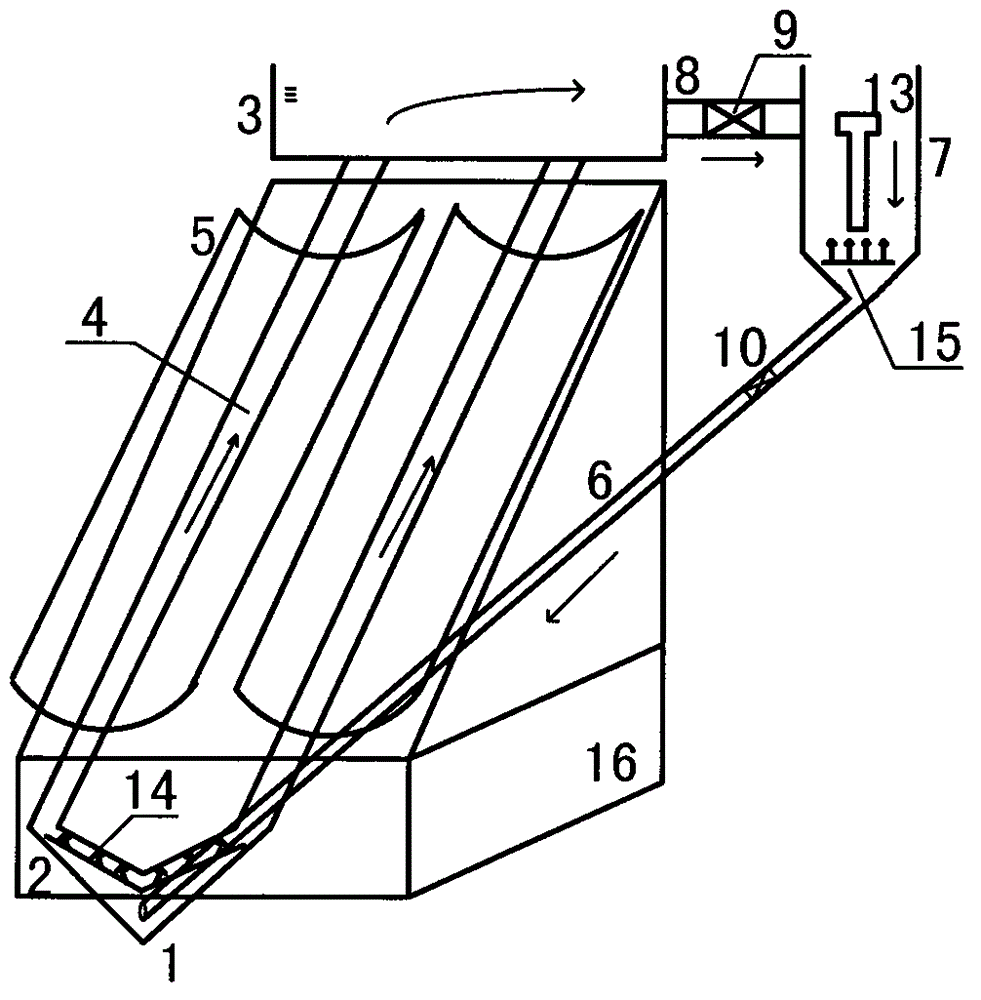

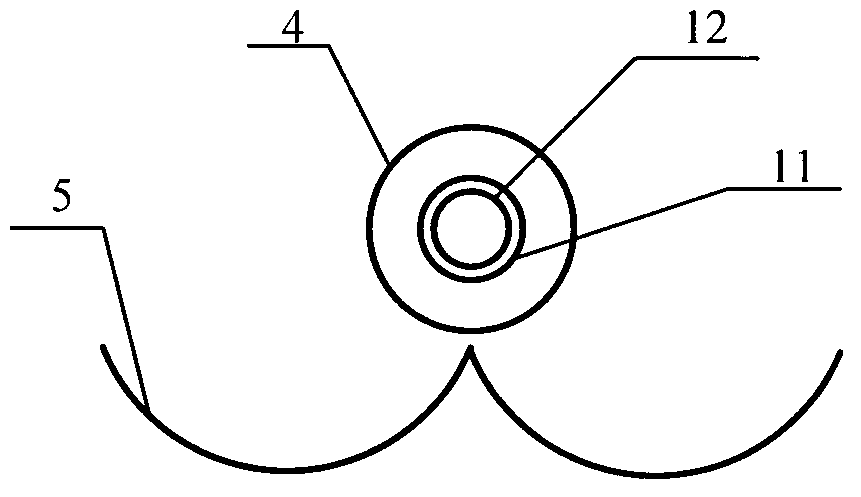

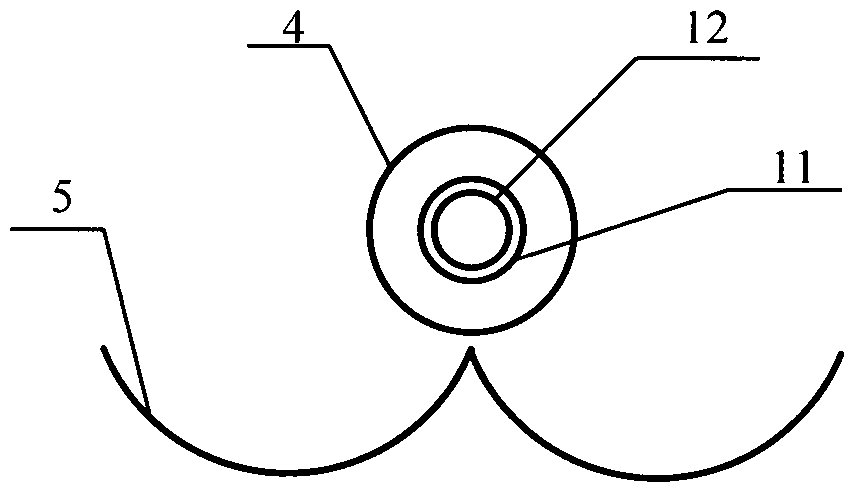

[0029]As shown in the accompanying drawings, the solar photocatalytic oxidation-membrane separation three-phase fluidized bed circulation reaction device of the present invention includes a photocatalytic reaction zone and a membrane separation zone, and the photocatalytic reaction zone includes a lower water tank 2 and an upper water tank 3 , compound parabolic daylighting plate 5 and tubular reactor, described tubular reactor is arranged on the central position of compound parabolic daylighting plate 5, wherein Fig. 2 (a) is solar photocatalytic oxidation-membrane separation three-phase fluidized bed circulation The cross-sectional view of the tubular reactor structure when the device is a dual light source structure, including high silica glass outer tube 4 and built-in quartz tube or quartz cold trap tube 11 and other quartz cooling tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com