Preparation method for Al2O3 ceramic material having controllable bimodal porous structure

A porous structure and ceramic material technology, applied in ceramic products, applications, household appliances, etc., can solve the problems that do not involve the controllability of porous alumina porosity and pore structure, and achieve easy large-scale industrial production and raw materials The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

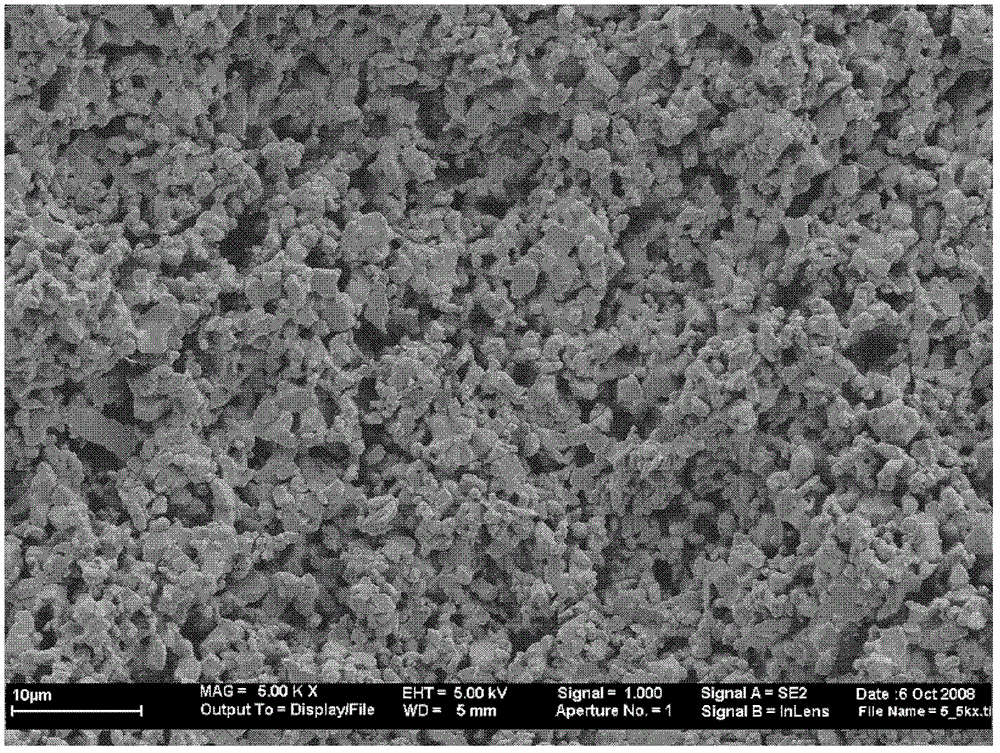

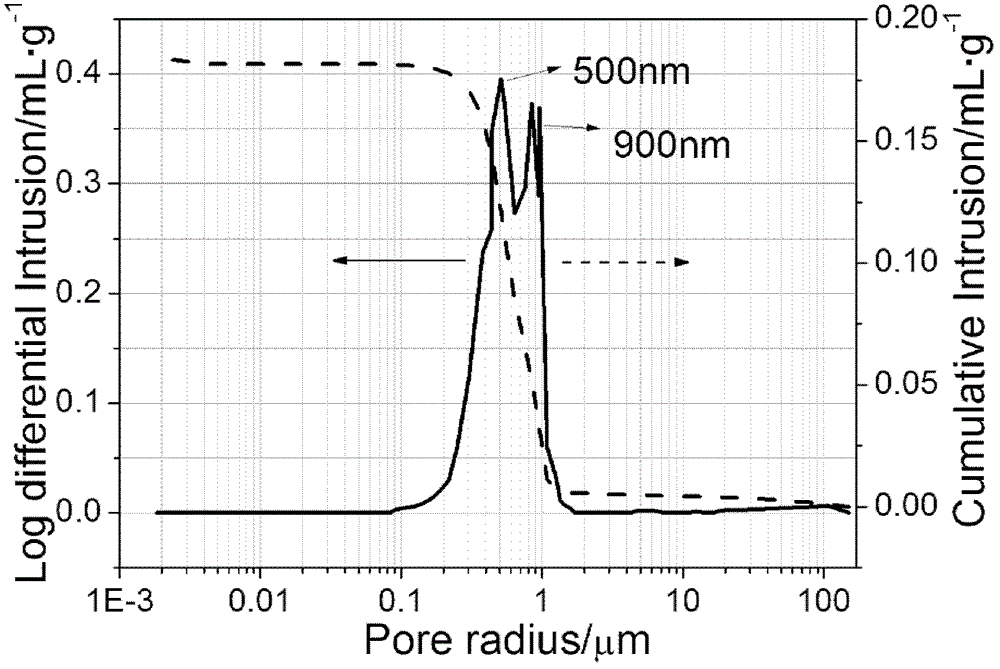

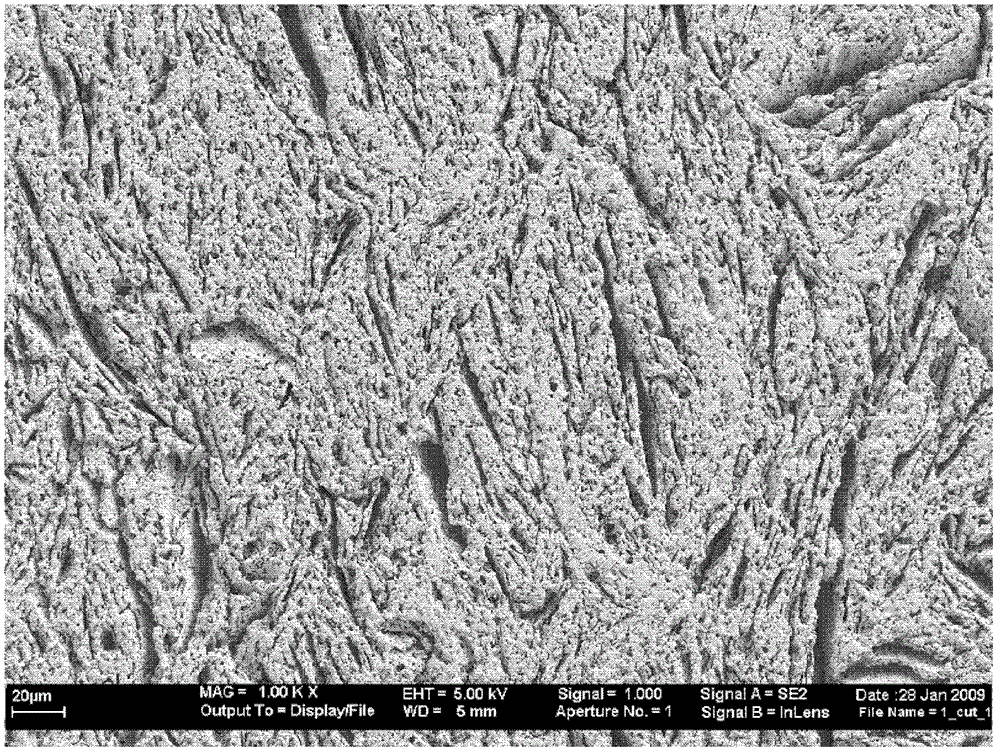

Image

Examples

Embodiment 1

[0035] A controllable bimodal porous structure Al 2 o 3 A ceramic material, the volume ratio of aluminum oxide in the material: spherical starch: fibrous carbon fiber is 4:1:1, and the preparation process includes the following steps:

[0036] In the first step, two pore formers of different shapes and different materials and alumina powder are passed through the following formula:

[0037] m 1 ρ 1 + m 2 ρ 2 = P × ( m 1 ρ 1 + m 2 ρ 2 + m 3 ...

Embodiment 2

[0045] A controllable bimodal porous structure Al 2 o 3 Ceramic material, the volume ratio of alumina:spherical starch:fibrous carbon fiber in the material is 14:3:3, and the preparation process is consistent with that of Example 1.

Embodiment 3

[0047] A controllable bimodal porous structure Al 2 o 3 Ceramic material, the volume ratio of alumina:spherical starch:fibrous carbon fiber in the material is 3:1:1, and the preparation process is consistent with that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com