Capillary penetration micro irrigation material and preparation method thereof

A capillary infiltration and micro-irrigation technology, applied in the directions of botanical equipment and methods, applications, watering devices, etc., can solve the problems of high overall production cost, high raw material cost, low production efficiency, etc., and improve the labor environment and labor intensity. Large, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

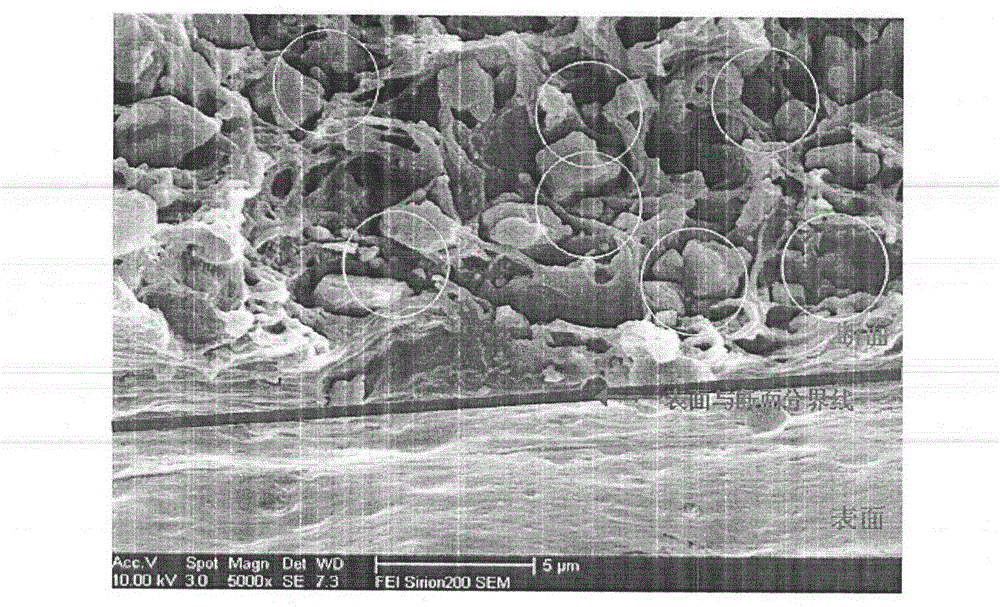

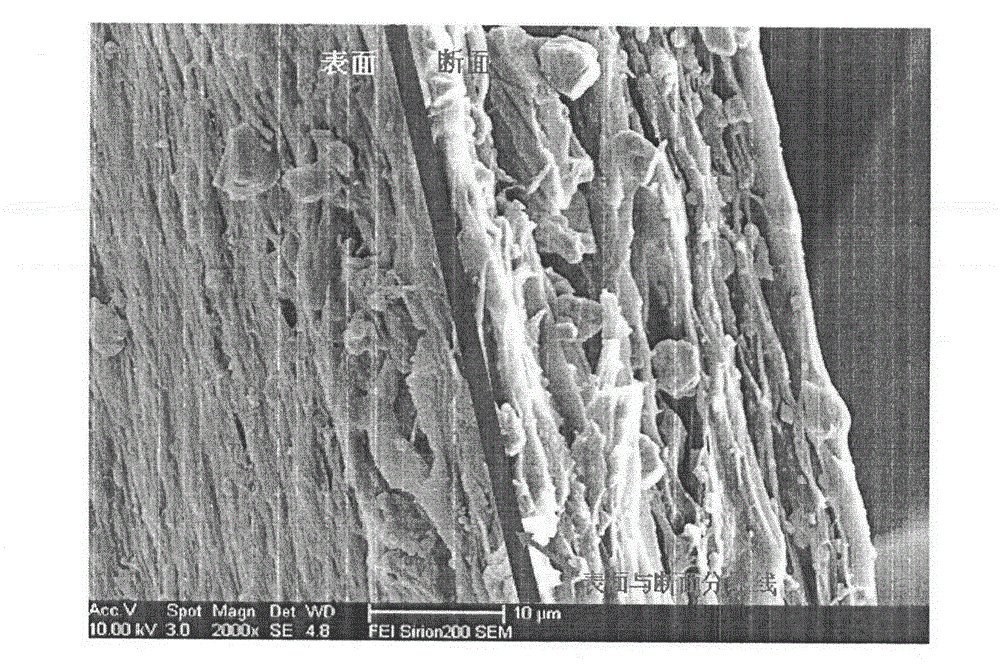

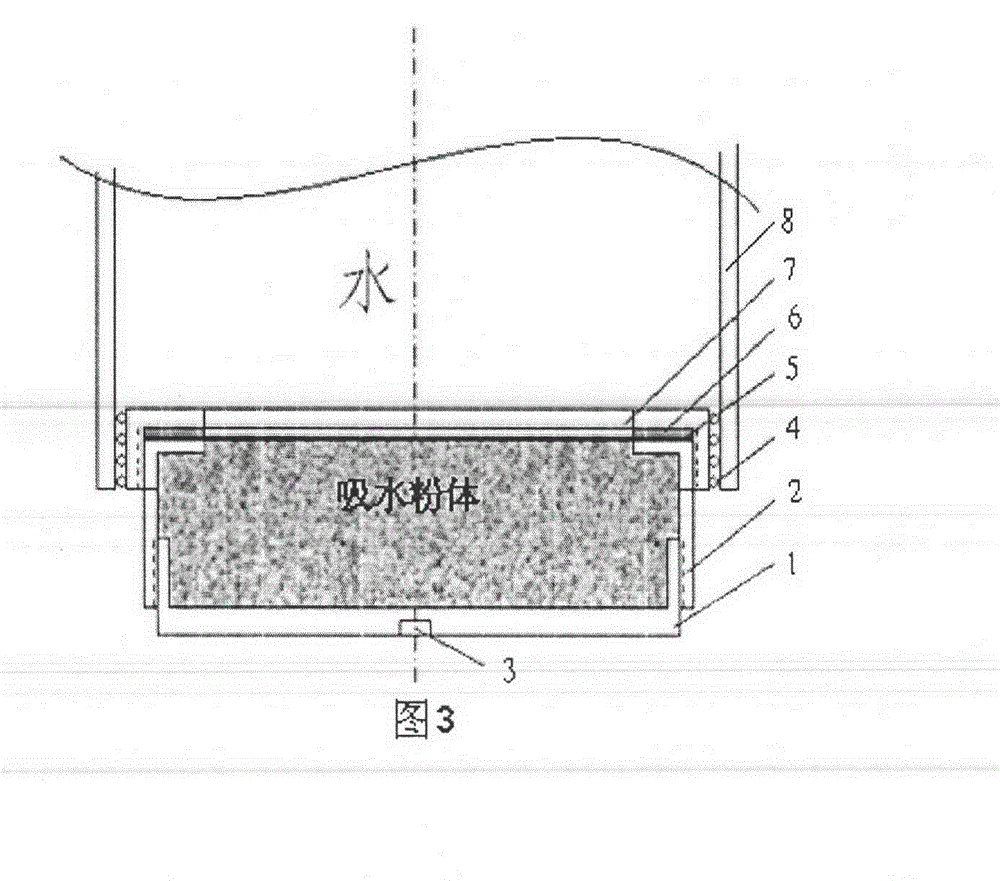

[0068] The salt sludge (slurry), a by-product of the chlor-alkali industry, is dried with a plate and frame filter press to remove excess water, then ground and sieved to obtain 10 micron (μ) salt sludge powder filler, using a melt flow rate (MFR) of 4 Linear low-density polyethylene (LLDPE) resin is used as the base material, and the mass ratio of filler to resin is 300: 100; auxiliary: hindered phenol antioxidant is tetra[β-(3.5-di-tert-butyl, 4- Hydroxyphenyl) propionic acid] pentaerythritol ester, the addition amount is 0.3 parts by mass, the phosphite stabilizer is tris (2.4-di-tert-butylphenyl) phosphite, the addition amount is 0.3 parts by mass; the average molecular weight is 4000 high-flow polyethylene (PE wax), the addition amount is 1 part by mass; the carbon black 40% carbon black masterbatch is 35 parts by mass. Add the above components in three stages according to the measurement. The first stage adds all the resins, additives and the corresponding proportion of f...

Embodiment 2

[0070] Use 6.5 microns (μm) calcium carbonate as the filler, low-density polyethylene (LDPE) resin with a melt flow rate (MFR) of 0.3 as the base material, and the mass ratio of the filler to the resin is 200:100; the auxiliary is :The hindered phenol antioxidant is tetrakis [β-(3.5-di-tert-butyl, 4-hydroxyphenyl) propionic acid] pentaerythritol ester, the addition amount is 0.3 parts by mass, and the phosphite stabilizer is tris(2.4 -Di-tert-butylphenyl) ester, the addition amount is 0.3 parts by mass; the high flow polyethylene (PE) with a melt flow rate (MFR) of 30, the addition amount is 1 part by mass. The above components are added into the twin-screw granulator in three stages according to the measurement. The first stage adds all the resins, additives and the corresponding proportion of fillers. The proportion of fillers added in each stage is 40% and 40% of the total filler. , 20%, using a twin-screw granulator with a screw diameter of 75 (φ75) and a length-to-diameter...

Embodiment 3

[0072] Use 1.6 micron (μm) calcium carbonate as the filler, high-density polyethylene (HDPE) resin with a melt flow rate (MFR) of 0.1 as the base material, and the mass ratio of filler to resin is 150:100; additives are: The hindered phenol antioxidant is tetra[β-(3.5-di-tert-butyl, 4-hydroxyphenyl) propionic acid] pentaerythritol ester, the addition amount is 0.3 parts by mass, and the phosphite stabilizer is tris(2.4- Di-tert-butylphenyl) ester, the addition amount is 0.3 parts by mass; the high flow polyethylene (PE) with a melt flow rate (MFR) of 70, the addition amount is 3 parts by mass. The above-mentioned components are added into the twin-screw granulator in four stages according to the measurement. The first stage adds all the resins, additives and the corresponding proportion of fillers. The proportion of fillers added in each stage is 30% and 30% of the total filler. , 30%, 10%, using a twin-screw granulator with a screw diameter of 75 (φ75) and a length-to-diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com