Modified flame-retardant composite resin, pipeline for pit water and preparation method thereof

A flame retardant composite, mine water technology, applied in rigid pipes, pipe protection, pipe damage/wear prevention, etc., can solve the problems of high humidity in mines, corrosion of metal pipes, insufficient strength, etc., to prevent metal corrosion, prevent corrosion, The effect of eliminating security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 of the present invention provides a modified flame-retardant composite resin, comprising the following components in parts by weight:

[0030] 5-10 parts of terpene resin,

[0031] 5-10 parts of zinc oxide,

[0032] 3-6 parts of ethoxylated alkylamine,

[0033] 2 to 5 parts of paraffin,

[0034] 1-2 parts of trinonylphenyl phosphite.

[0035] The modified flame-retardant composite resin provided in this embodiment is coated on the surface of the metal pipe, which can effectively prevent the corrosion of the metal pipe. The actual test data shows that the flame retardant effect can reach V0 level, and it can be coated on the surface of the metal pipe to form a smooth, uniform color coating without defects such as pinholes and scars, which can prevent the corrosion of metal pipes and meet the requirements of mine pipes. National requirements are conducive to eliminating potential safety hazards.

[0036] In this embodiment, in order to further improve th...

Embodiment 2

[0045] This example provides a method for preparing a modified flame-retardant composite resin, the formula of which is as follows:

[0046] 5-10 parts of terpene resin,

[0047] 5-10 parts of zinc oxide,

[0048] 3-6 parts of ethoxylated alkylamine,

[0049] 2 to 5 parts of paraffin,

[0050] 1-2 parts of trinonylphenyl phosphite.

[0051] Described preparation method comprises the steps:

[0052] (1) Weigh each component of the ratio and mix them evenly;

[0053] (2) Put the components uniformly mixed in step (1) into a granulator for extrusion granulation;

[0054] (3) Sieve and size the granules extruded from the granulator;

[0055] (4) Dry the sized particles at 60-80°C for 4-6 hours to make a modified flame-retardant composite resin material with a particle size of 30-60 mesh.

[0056] The modified flame-retardant composite resin prepared by the method provided in this example is coated on the surface of the metal pipe to form a dense coating, which can effective...

Embodiment 3

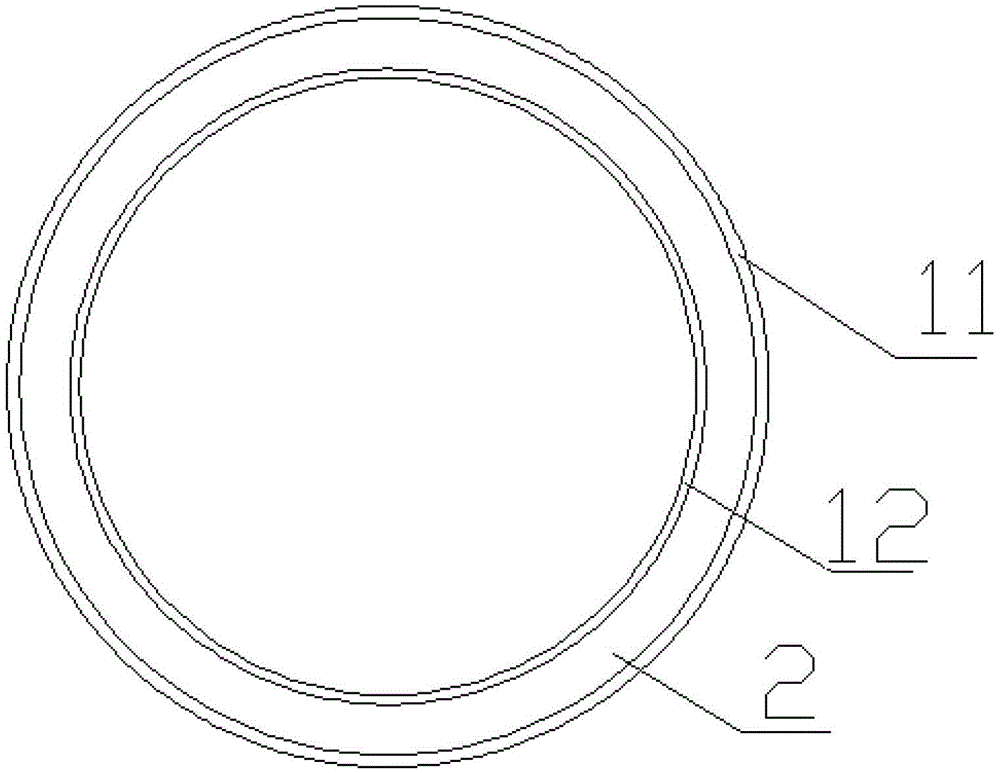

[0066] see figure 1 , the pipeline for mine water of the present embodiment includes a metal pipe body 2 and a modified flame-retardant composite resin coating coated on the surface of the metal pipe, and the modified flame-retardant composite resin coating includes an inner coating 12 and an outer coating For layer 11, the modified flame-retardant composite resin is the resin described in Example 1.

[0067] The pipeline for mine water in this embodiment is coated with a modified flame-retardant composite resin coating on the surface of the metal pipe, which can effectively prevent the corrosion of the metal pipe, and because of the support of the metal pipe, the strength is relatively high, which can meet the requirements for use in mines. , the mine water pipeline surface resistance of the present invention is 1 × 10 3 ~1×10 5 , the flame retardant effect can reach V0 level, the inner and outer coatings are smooth, the color is uniform, there are no defects such as pinhol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com