Stripping agent of indigo dyed pure cotton jean and stripping method thereof

A technology for denim and color stripping agent, applied in dyeing method, textile and papermaking, etc., can solve the problems of damage to cotton fiber performance, high contamination rate of stripping liquid, environmental pollution of waste liquid, etc., achieving good environmental protection, stripping good color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] 1. Experimental objects and auxiliaries

[0035] The fabric is indigo-dyed cotton denim.

[0036] Component description (mass percentage) of stripping agent:

[0037] Penetrant 5-10%

[0038] Dispersant 20-25%

[0039] water balance

[0040] 100%.

[0041] The penetrating agent is alkylbenzene sulfonate, which can also be replaced by aliphatic hydrocarbon and olefin sulfonate, fatty alcohol and fatty alcohol ether sulfate, fatty alcohol and fatty alcohol polyoxyethylene ether phosphate, and the same effect can also be obtained.

[0042] The dispersant is polyethylene glycol, which can also be replaced by polyether-type nonionic surfactants, polyvinylpyrrolidone, polyvinyl alcohol, and polyacrylic acid, and the same effect can also be obtained.

[0043] 2. Stripping process

[0044] The process prescription is as follows:

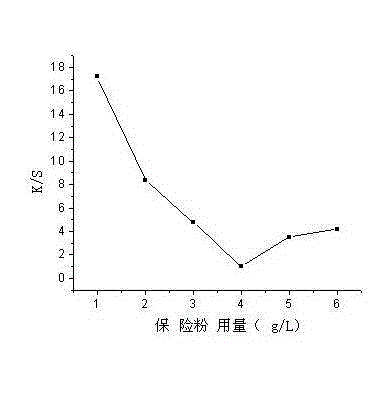

[0045] Hydrosulfite 4-5g / L

[0046] Caustic soda (100%) 2-3 g / L

[0047] Pingping plus O 3-5 g / L

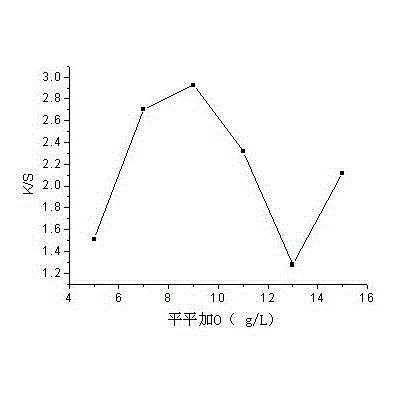

[0048] Stri...

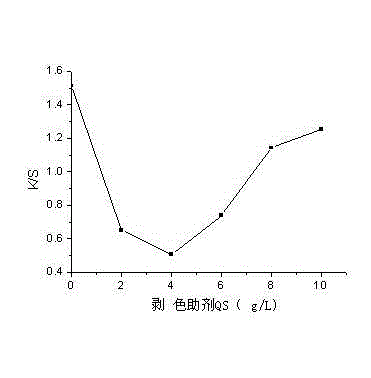

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com