Luminescent solar concentrator and preparation method thereof

A concentrator, solar energy technology, applied in photovoltaic power generation, semiconductor devices, final product manufacturing, etc., can solve the problems of low FQY, inconsistent with green chemistry, high price, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042]

[0043] The method for preparing the solar fluorescent concentrator of the present invention includes the following steps (1)-(4).

[0044] (1) Synthesis of PbS quantum dots by pyrolyzing sulfur-containing metal-lead organic complexes

[0045] Take lead nitrate and sodium diethyldithiocarbamate (copper reagent) (the mass ratio of lead nitrate to sodium diethyldithiocarbamate is preferably 6-8:10, more preferably 7-7.5:10.) respectively Dissolve in deionized water, mix and stir the two solutions to produce a white precipitate, resonate the mixed solution in an ultrasonic resonance cleaner to make the precipitate evenly mixed, and obtain the precipitate by filtering or other means. After washing the precipitate, dry it in a drying oven (such as an electric heating constant temperature drying oven at 80° C.) to obtain the sulfur-containing metal lead organic complex precursor powder. Disperse the obtained precursor powder in a mixed solvent of oleic acid and octadecene...

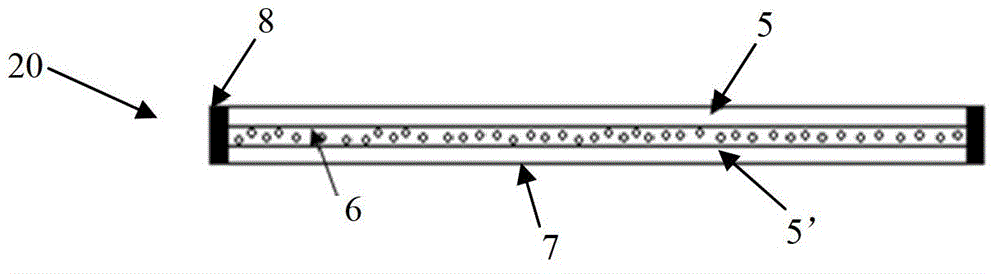

Embodiment 1

[0061] (1) Synthesis of PbS quantum dots by pyrolyzing sulfur-containing metal-lead organic complexes

[0062] Dissolve analytically pure lead nitrate (1.6560g) and sodium diethyldithiocarbamate (copper reagent) (2.2531g) in deionized water respectively, mix and stir the two solutions to produce a white precipitate, and the mixed solution is ultrasonically Resonate in the resonance cleaner for 5 minutes to mix the precipitate evenly, and then filter to obtain the precipitate. The precipitate was washed once with deionized water and twice with absolute ethanol, and then dried in an electric heating constant temperature drying oven at 80° C. to obtain a sulfur-containing metal lead organic complex precursor powder. The obtained precursor powder was dispersed in a mixed solvent of oleic acid and octadecene (volume ratio 1:1), and heated and decomposed at 280°C under the protection of argon to finally obtain PbS quantum dots. The particle size of the PbS quantum dots was measured...

Embodiment 2

[0071] In addition to replacing the 20×20×0.2cm quartz glass plate used in the step (3) of Example 1 with a 30×30×0.2cm quartz glass plate, and the length used in the step (4) of Example 1 Except that the silicon-based solar cell strip with a length of 20 cm and a width of 0.7 cm is replaced with a silicon-based solar cell strip with a length of 30 cm and a width of 0.7 cm, the solar fluorescent concentrator prototype 2 is prepared in the same way as in Example 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com