Etchant composition

A technology of composition and etching solution, applied in the directions of surface etching compositions, chemical instruments and methods, can solve problems such as uneconomical, complicated etching process, etc., and achieve the effects of increased production and simple etching process

Active Publication Date: 2012-10-24

DONGWOO FINE CHEM CO LTD +1

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the etching process becomes complicated and uneconomical

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

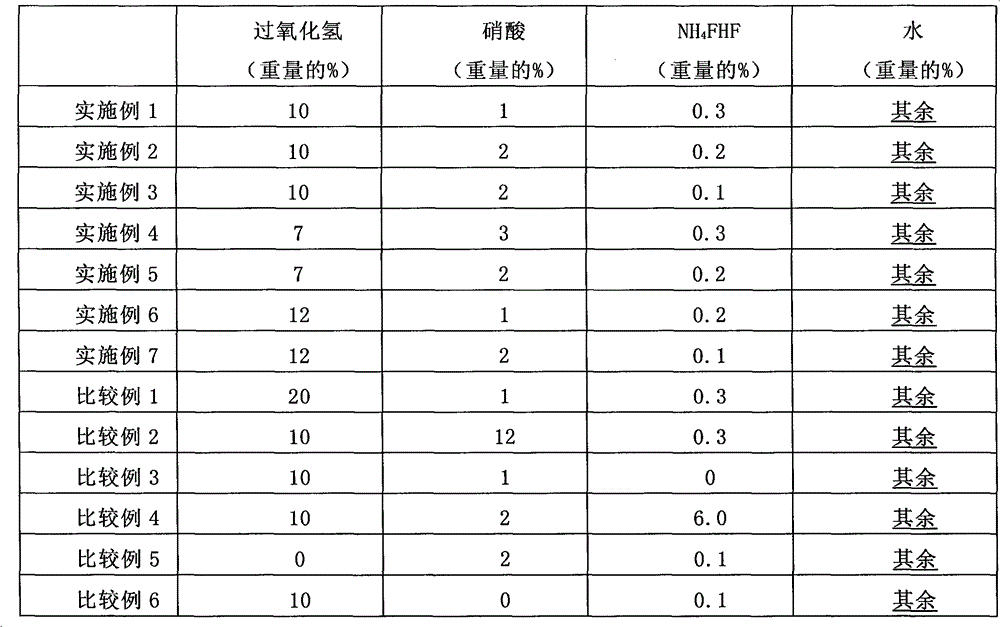

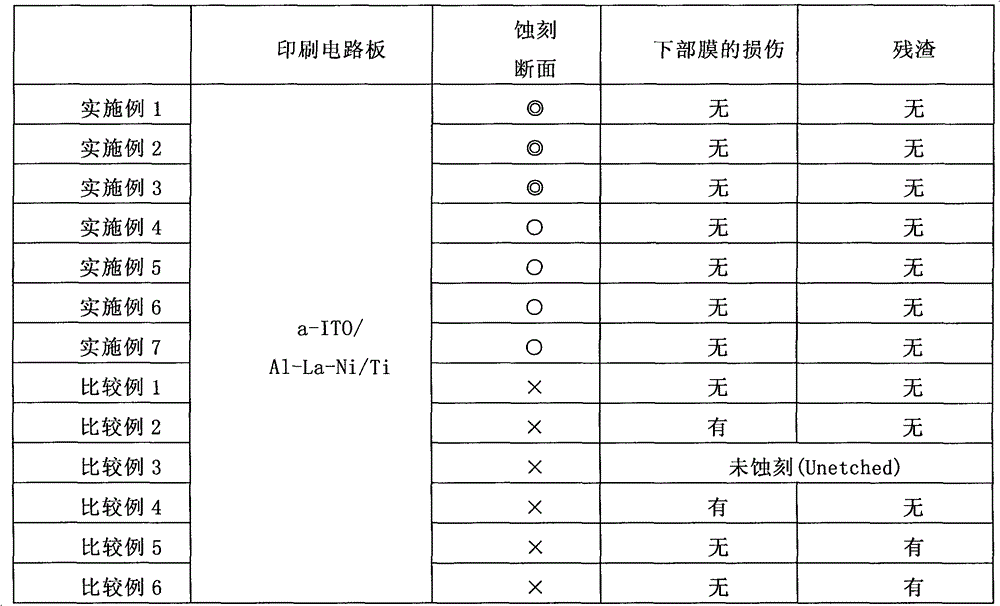

Embodiment 1~ Embodiment 7 and comparative example 1~ comparative example 6

[0025] Example 1-Example 7 and Comparative Example 1-Comparative Example 6: Manufacture of Etching Solution Composition

[0026] 180 kg of etching solution compositions were manufactured according to the components and composition ratios listed in Table 1 below.

[0027] Table 1

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to an etchant composition for etching a triple film consisting of an indium-based metal film, an aluminum-lanthanum-based alloy film, and a titanium-based metal film, wherein the etchant composition comprises: 1 to 15 wt % of hydrogen peroxide; 0.1 to 10 wt % of inorganic acid; and 0.01 to 5 wt % of a fluorine compound, with the remainder being water.

Description

technical field [0001] The invention relates to an etchant composition of a triple film composed of an indium series metal film, an aluminum-lanthanum series alloy film and a titanium series metal film. Background technique [0002] In flat panel display devices, the process of forming metal wiring on a printed circuit board generally consists of a process of forming a metal film by sputtering, coating a photoresist on the metal film, and exposing the photoresist to light. And development is comprised of the process of forming a photoresist within a selected range, and the process of etching a metal film. In addition, individual washing steps performed before or after the unit steps are also included. This etching process refers to a process of using a photoresist as a mask to leave a metal film in a selected range. In the etching step, dry etching using plasma or the like, or wet etching using an etching solution is generally used. [0003] On the other hand, in a flat p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K13/08C23F1/20C23F1/30

CPCC09K13/08C23F1/16

Inventor 李昔准慎蕙驘权五柄李喻珍

Owner DONGWOO FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com