Oily sludge treatment process and device

A technology for sludge treatment and oil sludge, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficult dross treatment, expensive equipment, low production efficiency, etc., to achieve Thorough separation, complete oil-water separation, fast processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

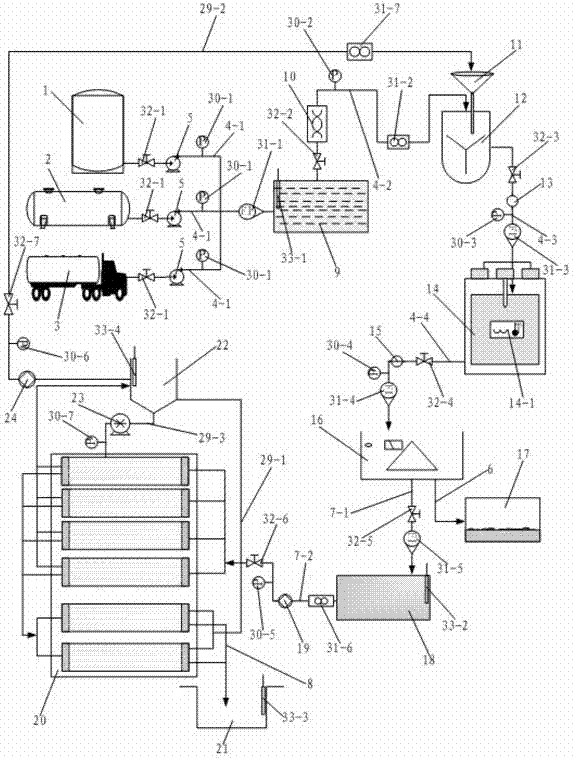

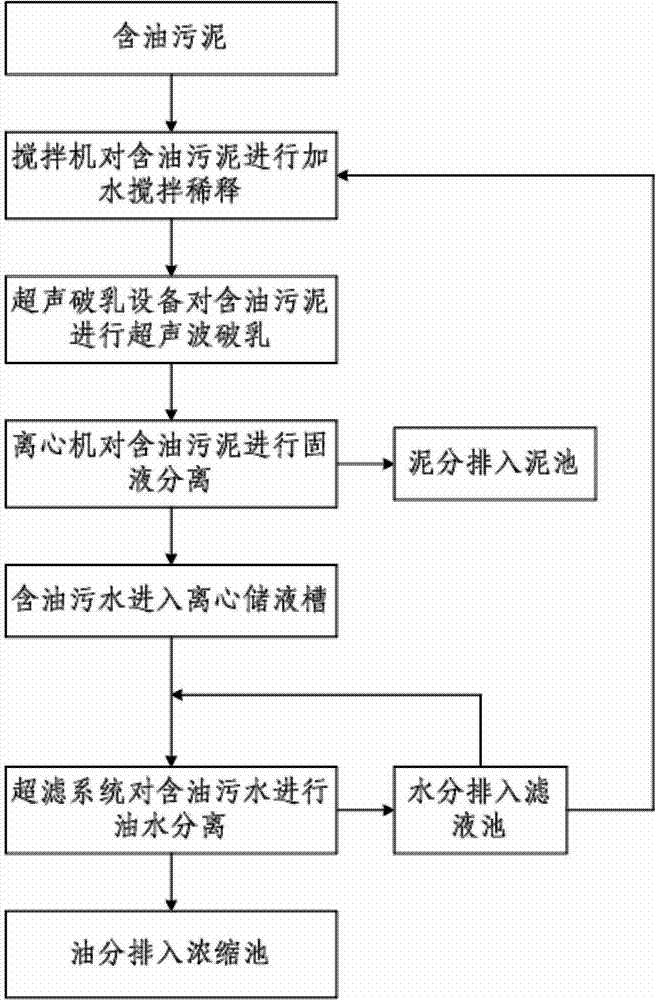

[0061] like figure 1 As shown, the oily sludge treatment process of the present invention comprises the following steps:

[0062] Step 1. Add water and stir to dilute: the oily sludge in the oil tank is stored in the sludge storage tank 9 through the centrifugal pump 5, enters the funnel 11 above the mixer 12 through the screw pump 10, enters the mixer 12 through the funnel 11, and the mixer 12 pairs Oily sludge is diluted with water;

[0063] Step 2, ultrasonic demulsification: the stirred and diluted oily sludge enters the ultrasonic demulsification equipment 14 through the first in-line pump 13, and the ultrasonic demulsification equipment 14 performs demulsification treatment on the oily sludge;

[0064] Step 3, solid-liquid separation: the oily sludge after demulsification enters the centrifuge 16 through the second in-line pump 15, and the centrifuge 16 performs solid-liquid separation treatment on the oily sludge to obtain sludge and oily sewage, and the sludge is disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com