Device and method for denitration and treating sludge containing organic matter by utilizing dry-method rotary kiln

A technology of organic matter and sludge, applied in the direction of dehydration/drying/concentrated sludge treatment, separation methods, chemical instruments and methods, etc., can solve the problems of difficult waste gas treatment, failure to find, shrinkage and easy collapse of materials, etc., to avoid disadvantages effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

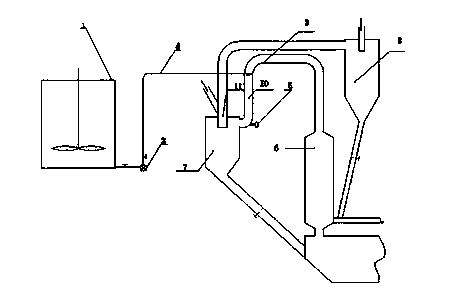

[0022] This embodiment is an embodiment of a device for treating sludge containing organic matter in a dry-process rotary kiln that takes into account denitrification, including a dry-process rotary kiln preheater system, and the dry-process rotary kiln preheater system includes a calciner 6, a calciner gooseneck Pipe 3, the fourth-stage cyclone 8, the fifth-stage cyclone 7, the fifth-stage cyclone to the fourth-stage cyclone ascending pipe 11, and the upper part of the fourth-stage cyclone 8 communicates with the top of the fifth-stage cyclone 7 through the ascending pipe 11. The first-stage cyclone 7 communicates with the calciner 6 through the calciner gooseneck 3, and is also provided with a sludge tank 1, a mud pump 2, and an air gun group 5, and the sludge tank 1 is provided with a power stirring device or an inflating device. The sludge tank 1 is connected to the downstream section 10 of the calciner gooseneck 3 through the mud conveying pipeline 4, between the sludge ta...

Embodiment 2

[0024] This example is an example of a method for treating sludge containing organic matter using the device for treating sludge containing organic matter in a dry-process rotary kiln with consideration of denitrification in Example 1. The specific operation steps are:

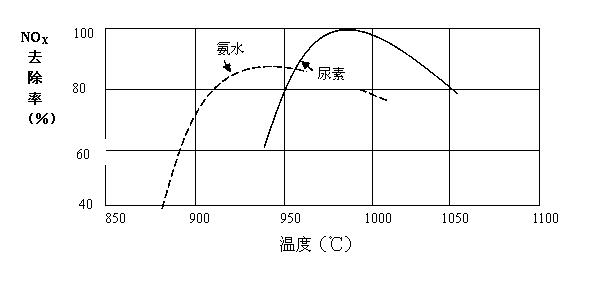

[0025]Use the mud pump (piston pump) 2 to spray the municipal sludge (moisture content 81wt%) in the sludge tank 1 into the space between the decomposition furnace 6 and the preheater five-stage cyclone 7 through the mud delivery pipeline 4 along the airflow direction In the descending section 10 of the gooseneck pipe 3 of the calciner, the amount of sludge injection is 5.0t / h. In the pipeline, the organic matter and water in the organic matter sludge are gasified and vaporized rapidly, and the inorganic matter is dried rapidly, and the The gooseneck of the calciner, the fifth-stage cyclone, the ascending pipe from the fifth-stage cyclone to the fourth-stage cyclone, and the area space of the fourth-stage cycl...

Embodiment 3

[0027] This embodiment is an embodiment of the method for treating sludge containing organic matter by using the device for treating sludge containing organic matter in a dry-process rotary kiln with consideration of denitrification in Embodiment 1. The specific operation steps are:

[0028] Use the mud pump 2 to spray the printing and dyeing factory sludge (moisture content 71wt%) in the sludge tank 1 into the calciner gooseneck between the calciner 6 and the five-stage cyclone 7 of the preheater through the mud conveying pipeline 4 along the airflow direction In the descending section 10 of the pipe 3, the amount of sludge sprayed is 3.5t / h. In the pipeline, the organic matter and water in the organic sludge are gasified and vaporized rapidly, and the inorganic matter is dried rapidly, and are discharged in the gooseneck of the calciner. Tube, fifth-stage cyclone, ascending pipeline from fifth-stage cyclone to fourth-stage cyclone, and area space denitration of fourth-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com