Low-molecular weight schisandra chinensis polysaccharides and preparation method and application thereof

A low-molecular-weight, schisandra technology, applied in the field of medicine, can solve the problems of no patent disclosure and no domestic and foreign literature reports, and achieve the effects of low cost, improving the immune function of the body, improving autoimmunity and antioxidant activity in the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

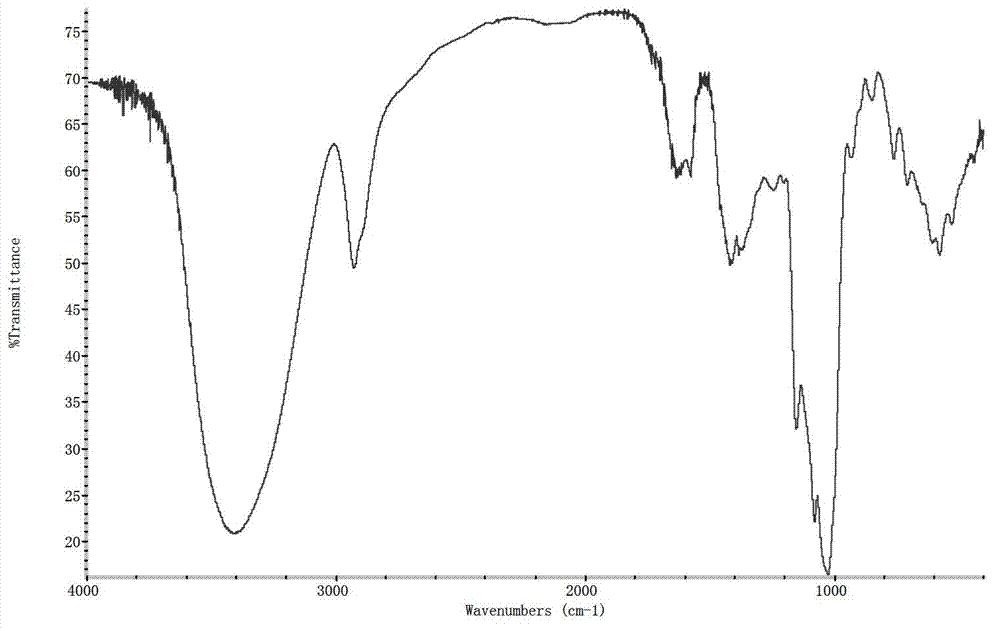

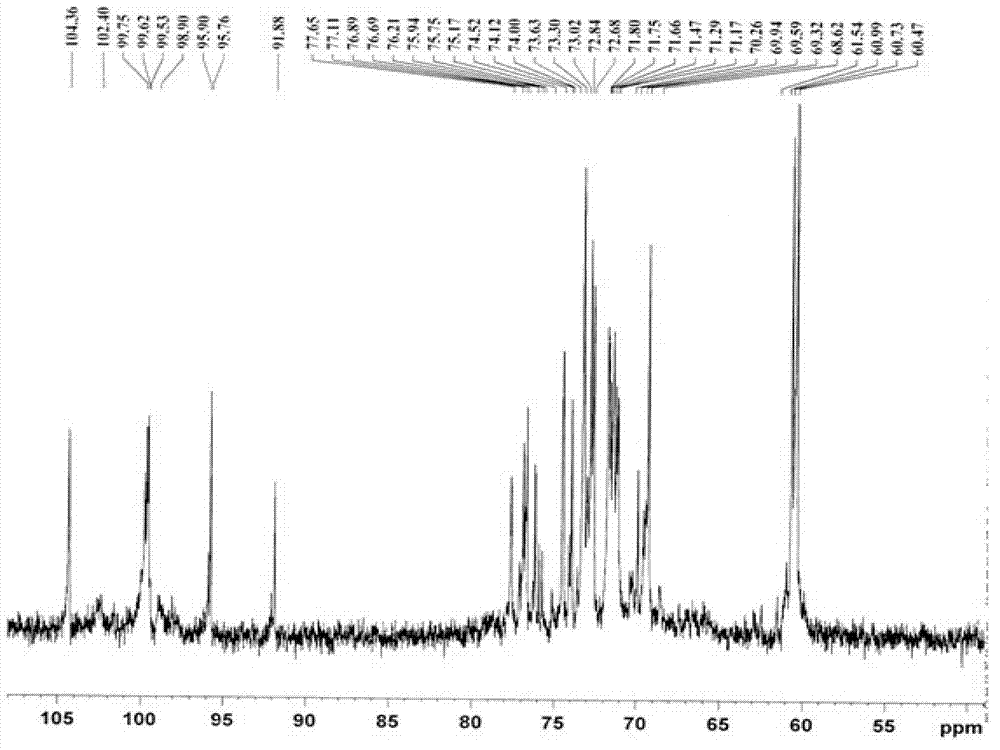

[0022] The raw materials were washed with water, dried at 60°C, pulverized, placed in a Soxhlet extractor, degreased with petroleum ether (distillation range 60-90°C) for 15 hours, filtered, and the filter residue was dried at 60°C for later use. Weigh 100g defatted Schisandra chinensis powder, put it in a round bottom flask, reflux and extract once in a hot water bath according to the ratio of material to liquid 1:8, extraction time 3h, extraction temperature 80°C, cool and centrifuge, combine the above Clear liquid: the above clear liquid is concentrated under reduced pressure, and 4 times the volume of 95% ethanol is added for precipitation, so that the concentration of ethanol in the concentrated solution of the polysaccharide is 80%, and the obtained precipitate is centrifuged and freeze-dried for 24 hours to obtain the crude polysaccharide sample powder of Schisandra chinensis; An appropriate amount of crude polysaccharide from Schisandra chinensis is reconstituted, and t...

Embodiment 2

[0024]The raw materials were washed with water, dried at 60°C, pulverized, placed in a Soxhlet extractor, degreased with petroleum ether (distillation range 60-90°C) for 15 hours, filtered, and the filter residue was dried at 60°C for later use. Weigh 100g of defatted schisandra powder, put it in a round bottom flask, reflux in a hot water bath for 2 times according to the material-to-liquid ratio of 1:10, extraction time of 4 hours, and extraction temperature of 90°C, then centrifuge after cooling, and combine Clear liquid: the above clear liquid is concentrated under reduced pressure, and 4 times the volume of 95% ethanol is added for precipitation, so that the concentration of ethanol in the concentrated solution of the polysaccharide is 80%, and the obtained precipitate is centrifuged and freeze-dried for 36 hours to obtain the crude polysaccharide sample powder of Schisandra chinensis; An appropriate amount of crude polysaccharide from Schisandra chinensis is reconstituted...

Embodiment 3

[0026] The raw materials were washed with water, dried at 60°C, pulverized, placed in a Soxhlet extractor, degreased with petroleum ether (distillation range 60-90°C) for 15 hours, filtered, and the filter residue was dried at 60°C for later use. Weigh 100g defatted Schisandra chinensis powder, put it in a round bottom flask, reflux and extract it in a hot water bath for 3 times according to the ratio of solid to liquid 1:12, extraction time 5h, extraction temperature 100°C, after cooling, centrifuge, combine the Clear liquid: the above clear liquid is concentrated under reduced pressure, and 4 times the volume of 95% ethanol is added for precipitation, so that the concentration of ethanol in the concentrated solution of the polysaccharide is 80%, and the obtained precipitate is centrifuged and freeze-dried for 48 hours to obtain the crude polysaccharide sample powder of Schisandra chinensis; An appropriate amount of crude polysaccharide from Schisandra chinensis is reconstitut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com