Low-temperature dry distillation equipment and method of low-rank coal and oil shale and petroleum residue

A technology for oil shale and low-rank coal, which is applied in the field of energy and chemical industry, can solve the problems of small output of a single set of equipment, low quality of gas production, and high production cost, and achieves improved safety and adjustability, high gas purity, and heat. less scatter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

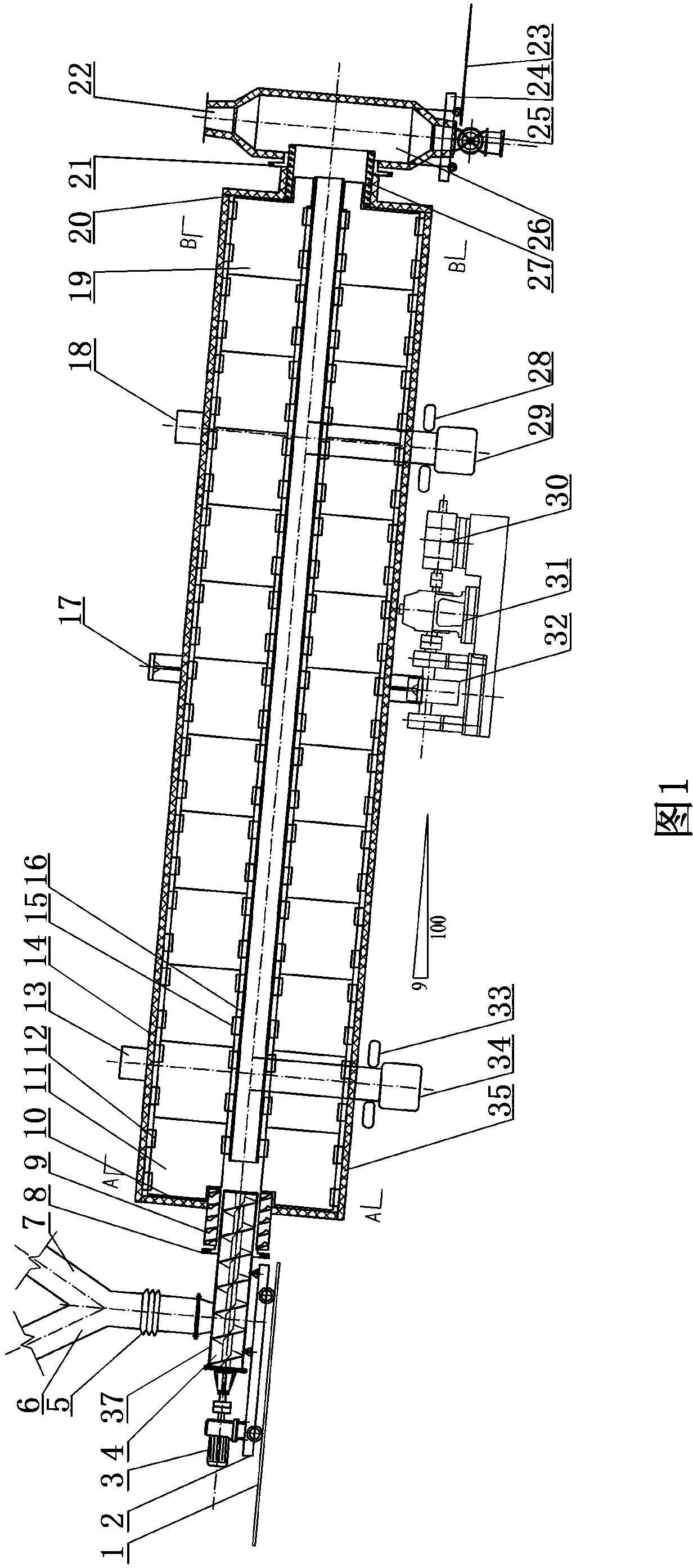

[0036] Examples see figure 1 As shown, this low-temperature retort equipment for low-rank coal, oil shale, and petroleum residue is composed of three parts: a retort furnace rotary main machine, a material and heating ceramic ball mixing screw feeder, and a gas-solid separation box. The material and heating The ceramic ball mixing screw feeder is connected to the feed end of the retort main machine, and the gas-solid separation box is connected to the discharge end of the retort main machine.

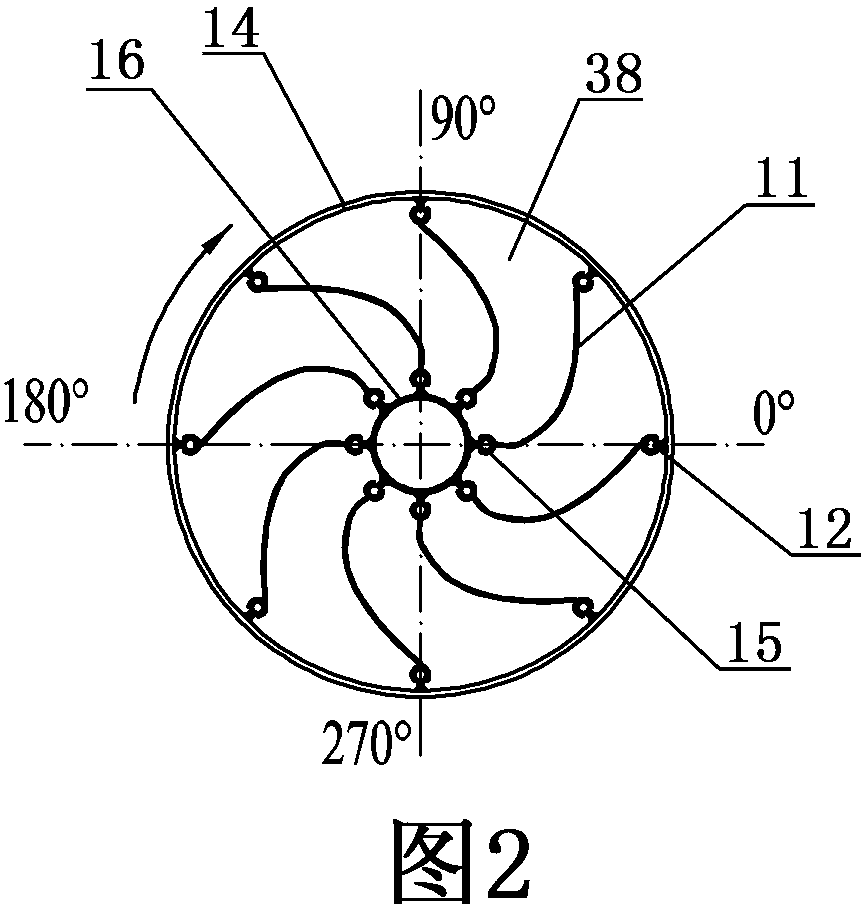

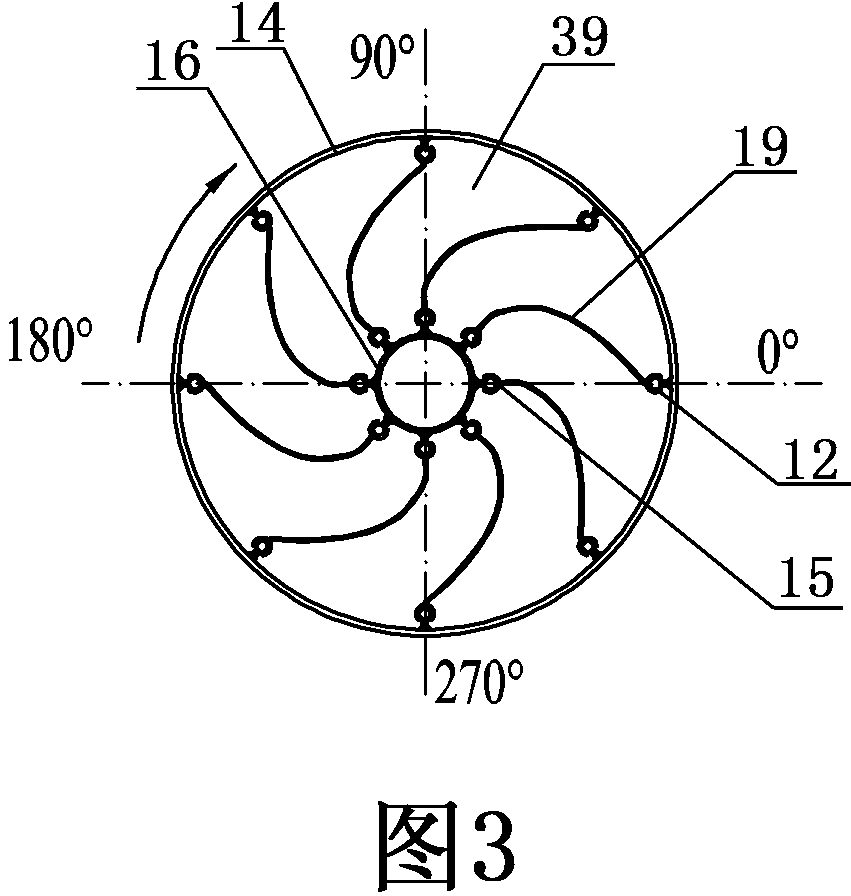

[0037] The retort main machine of the retort furnace is a cylindrical structure arranged obliquely downward from the feed end to the discharge end; the outer wall of the outer cylinder 14 of the retort main machine is covered with a layer of refractory material 35, and the central axis of the outer cylinder 14 of the retort main machine is There is an inner cylinder 16, and the inner cylinder 16 and the outer cylinder 14 are connected together by a plurality of arc-shaped plates arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com