Funnel type lithium battery diaphragm and production method thereof

A technology for lithium battery separators and production methods, which is applied to battery components, circuits, electrical components, etc., can solve the problems of general liquid-hanging ability of microporous membranes, unfavorable ion passage, and unstable porosity, etc., and achieve overall tensile strength The effect of good strength, uniform micropore density and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

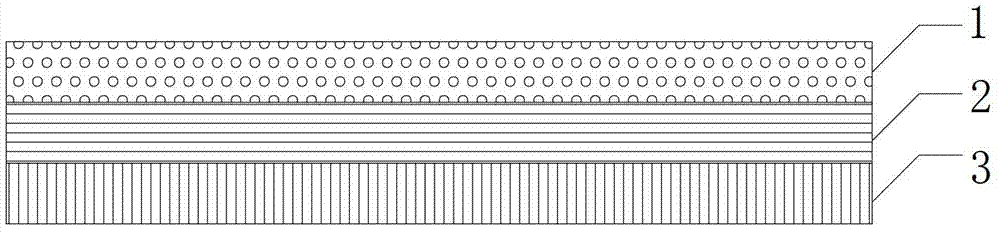

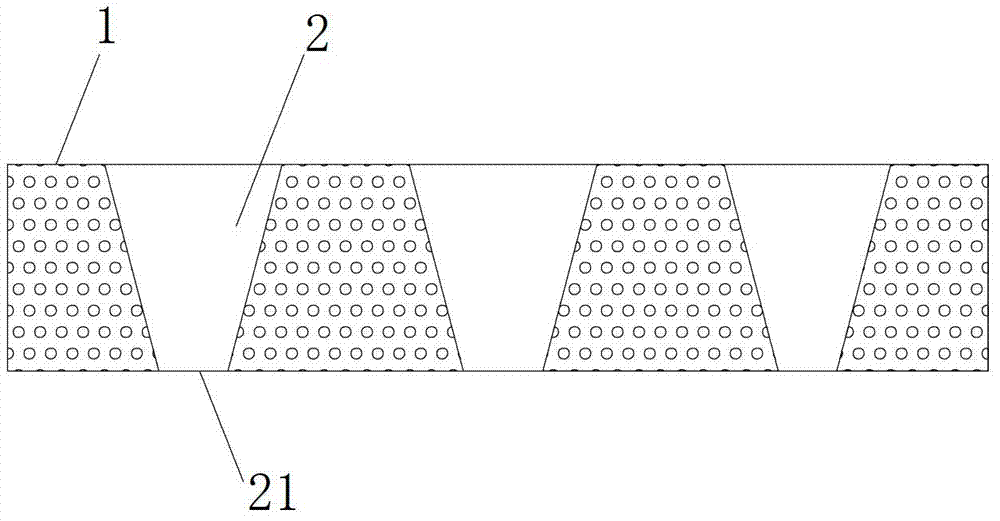

[0024] as attached figure 1 , 2 As shown, a funnel-shaped lithium battery separator includes a base film layer 1, one side of the base film layer 1 is bonded with an anti-etching protective film layer 3 through a release agent and a glue layer 2, and the inside of the base film layer 1 is uniformly distributed There are funnel-shaped micropores and micropores 11 .

[0025] The ratio of the largest diameter to the smallest diameter of the micropores 11 is 3:1 to 10:1.

Embodiment 2

[0027] A method for producing a funnel-type lithium battery diaphragm, comprising the following steps:

[0028] 1) Using polyethylene terephthalate plastic film as the substrate, irradiating the plastic film with high-energy particles;

[0029] The irradiation power is 2,000-10,000 kilowatts, the irradiation time is 0.5-200 seconds, and the micropore density is adjusted by adjusting the irradiation energy and irradiation time to obtain a micropore density ranging from 100,000 to 20 million per square centimeter;

[0030] 2) Coat release agent and glue on either side of the plastic film, and then compound a layer of anti-etching protective film;

[0031] 3) Dip the composite plastic film in a solution containing acid or alkali for etching reaction. The etching reaction temperature is 70°C-90°C, the etching time is 0.2-60 minutes, and the obtained micropore diameter ranges from 0.5 microns to 5 microns, the pore size can be finely adjusted by adjusting the concentration of lye ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com