Sandwich material of corrugation-aluminum honeycomb composite structure and preparation method of sandwich material

A composite structure and interlayer material technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of low mechanical properties, low relative density, low structural properties, etc., and achieve excellent comprehensive performance and simple manufacturing process. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

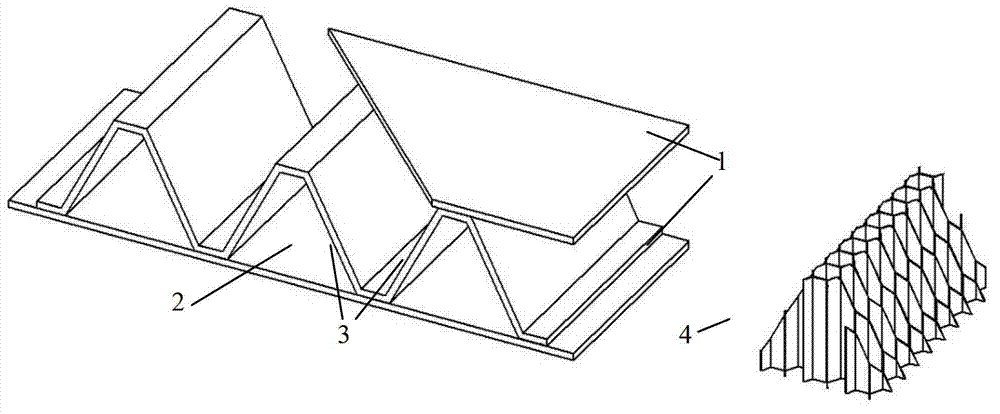

[0022] Example 1: 1) Firstly, the flattened carbon steel plate with a thickness of 0.1mm is molded or folded into a metal corrugated core 2 with a platform structure 6, that is, a trapezoidal structure, and then the metal corrugated core 2 and a metal panel (carbon steel plate) with a thickness of 1 mm 1 Use a metal cleaning agent to remove oil and rust and then dry;

[0023] 2) Then, use the wire cutting technology to make the wire perpendicular to the direction of the honeycomb holes to cut the plate-shaped aluminum honeycomb core into a trapezoidal aluminum honeycomb core material 4 that matches the hole 3 of the metal corrugated core 2. The plate-shaped aluminum honeycomb core is pure aluminum Honeycomb or aluminum alloy honeycomb with a porosity of 98%;

[0024] 3) Secondly, evenly coat a layer of 0.1mm thick adhesive polyurethane resin on the inner surface of the hole 3 of the corrugated structure core 2 or the outer surface of the trapezoidal aluminum honeycomb core mat...

Embodiment 2

[0027] Example 2: 1) First, the metal corrugated core 2 with a platform structure 6, that is, a trapezoidal structure, is made of a flattened metal plate stainless steel plate with a thickness of 0.5 mm by molding or folding technology, and then the metal corrugated core 2 and the Metal panel (stainless steel plate) with a thickness of 0.5mm 1 Use metal cleaning agent to remove oil and rust and then dry;

[0028] 2) Then, use the wire cutting technology to make the wire perpendicular to the direction of the honeycomb holes to cut the plate-shaped aluminum honeycomb core into a trapezoidal aluminum honeycomb core material 4 that matches the hole 3 of the metal corrugated core 2. The plate-shaped aluminum honeycomb core is pure aluminum Honeycomb or aluminum alloy honeycomb with a porosity of 98%;

[0029] 3) Secondly, evenly coat a layer of 0.2mm thick adhesive epoxy resin on the inner surface of the hole 3 of the corrugated structure core 2 or the outer surface of the trapezoi...

Embodiment 3

[0032] Example 3: 1) First, the metal corrugated core 2 with a platform structure 6, that is, a trapezoidal structure, is made of a flattened metal sheet aluminum plate with a thickness of 1.0mm by molding or folding technology, and then the metal corrugated core 2 and the thickness For 1.5mm metal panel (aluminum alloy plate) 1, use metal cleaning agent to remove oil and rust and then dry;

[0033] 2) Then, use the wire cutting technology to make the wire perpendicular to the direction of the honeycomb holes to cut the plate-shaped aluminum honeycomb core into a trapezoidal aluminum honeycomb core material 4 that matches the hole 3 of the metal corrugated core 2. The plate-shaped aluminum honeycomb core is pure aluminum Honeycomb or aluminum alloy honeycomb with a porosity of 98%;

[0034] 3) Secondly, evenly coat a layer of 0.15mm thick adhesive epoxy resin on the inner surface of the hole 3 of the corrugated structure core 2 or the outer surface of the trapezoidal aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com