Method for purifying sulfur hexafluoride and purifying and solidifying tank of sulfur hexafluoride

A technology of sulfur hexafluoride gas and sulfur hexafluoride, which is applied in the direction of sulfur and halogen compounds, can solve the problems of small processing capacity, low processing speed, wasting gas environment, etc., and achieve the goal of reducing unnecessary waste and reducing environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

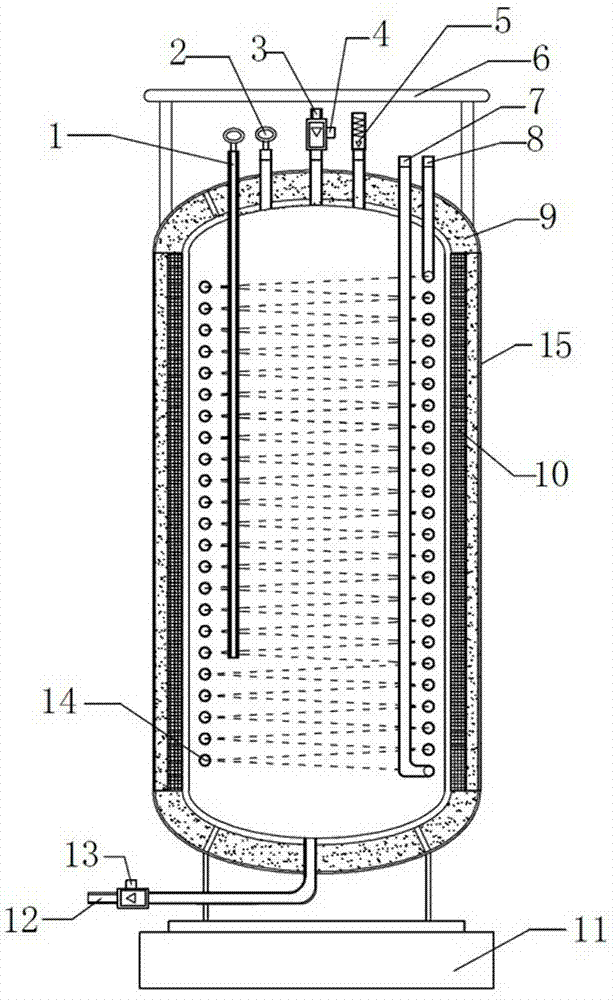

[0018] Sulfur hexafluoride gas purification, purification and solidification tank of the present invention has a structure such as figure 1 As shown, a double-layer stainless steel tank body 15 is provided with an insulating layer 9 inside the tank body 15, a heater 10 is arranged inside the insulating layer 9, an air inlet 3 and an air inlet valve 4 are arranged on the top of the tank body 15, and the liquid nitrogen refrigeration coil 14 In the tank body 15, a liquid nitrogen inlet 7 and a liquid nitrogen gas outlet 8 are respectively provided to communicate with the outside of the tank, a liquid outlet 12 and a liquid outlet valve 13 are arranged at the bottom of the tank, and the tank 15 is arranged on the weighing mechanism 11 on.

[0019] The tank body 15 is also provided with a temperature sensor 1 and a pressure transmitter 2 , a pressure relief valve 5 is provided at the top, and a protective ring 6 is provided at the top of the tank body 15 .

[0020] The sulfur hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com