Biohydrogen production method and device adopting hydrophyte and animal manure light-dark cascade coupling

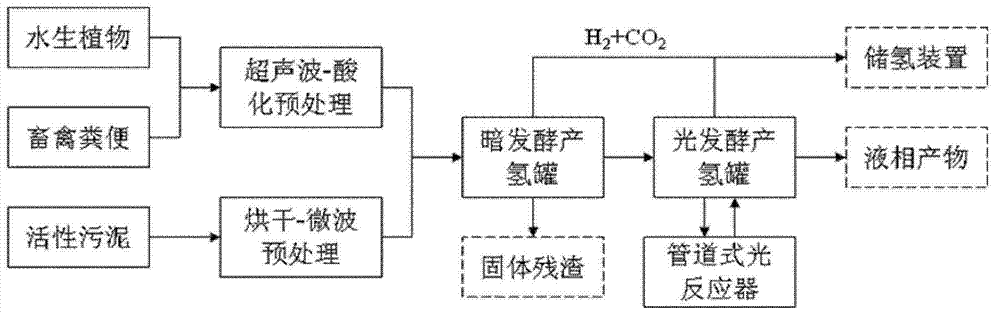

A technology of livestock and poultry manure and aquatic plants, applied in the direction of microorganism-based methods, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problems of low hydrogen production and unstable hydrogen production in dark fermentation, and shorten the start-up time, alleviating the energy crisis, and improving the efficiency of hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

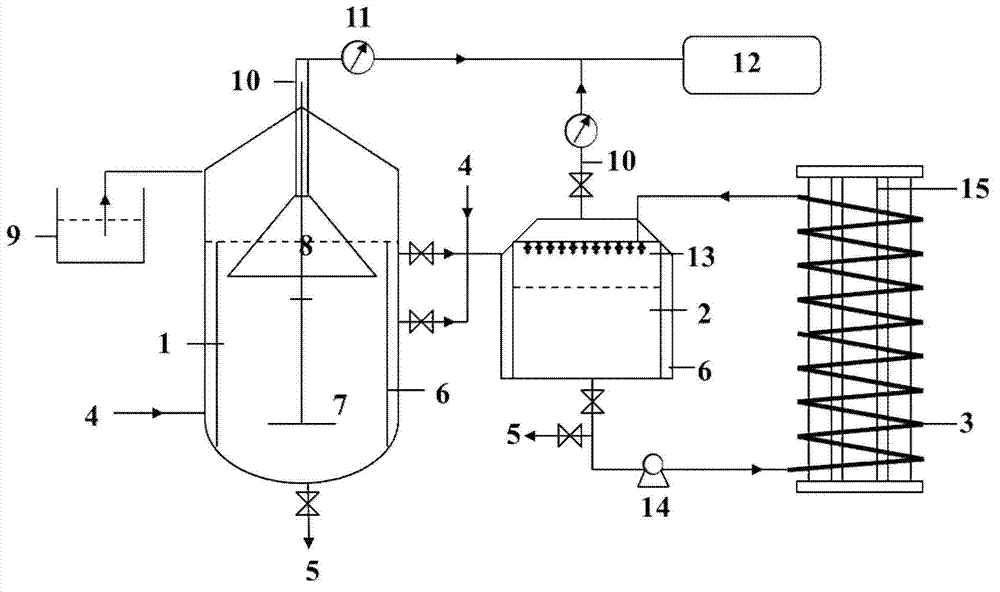

[0054] Implementing device of the present invention such as figure 2 As shown, the reaction device includes a dark fermentation hydrogen production tank 1 , a photofermentation hydrogen production tank 2 , and a pipeline photoreactor 3 . The tank body of the dark fermentation hydrogen production tank 1 is made of stainless steel. The top of the tank body is provided with a biogas outlet 10, the middle part is provided with a feed port 4, and the bottom is provided with a discharge port 5. The temperature is controlled through the external heating jacket 6 of the tank body. The fermentation hydrogen production tank is equipped with a stirrer 7 and a three-phase separator 8 to realize the separation of solid, liquid and gas. The photofermentation hydrogen production reactor is connected in series with the dark fermentation hydrogen production tank. The photofermentation hydrogen production reactor is composed of a photofermentation hydrogen production tank 2 and a pipeline phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com