Method for electrodepositing Al protective plated layer on surface of NdFeB magnet by using ionic liquid

An ionic liquid and electrodeposition technology, applied in the field of material surface coating protection, can solve problems such as complex process, inability to deposit aluminum coating, poor coating adhesion, etc., and achieve simple process and operation, easy promotion and implementation, and environmentally friendly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

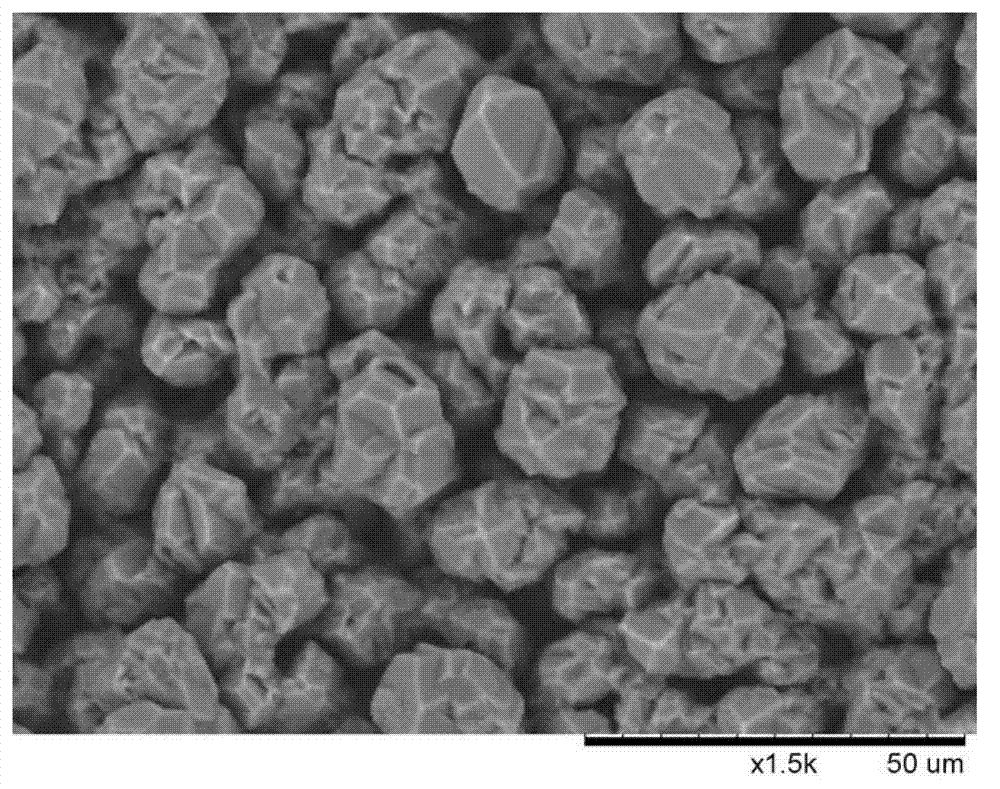

Embodiment 1

[0031] (1) Preparation of ionic liquid

[0032] Weigh BMIC (1-butyl-3-methylimidazole chloride) and aluminum chloride anhydrous according to the molar ratio of 1:2, add aluminum chloride anhydrous slowly in BMIC several times, and constantly Stir continuously, and the rate of adding aluminum chloride should be as slow as possible, otherwise the ionic liquid will be overheated and decomposed due to the exothermic reaction, and white smoke will be emitted. After the aluminum chloride is added, the mixed ionic liquid is magnetically stirred for about 24 hours to ensure that the aluminum chloride is completely dissolved, and finally a pale yellow transparent ionic liquid is obtained. A piece of aluminum wire is put into the prepared ionic liquid, which is used to refine the ionic liquid to replace the trace impurity heavy metal ions in it, and it can be used for electrodeposition after about 24 hours of treatment. The configuration of the ionic liquid and the subsequent electrode...

Embodiment 2

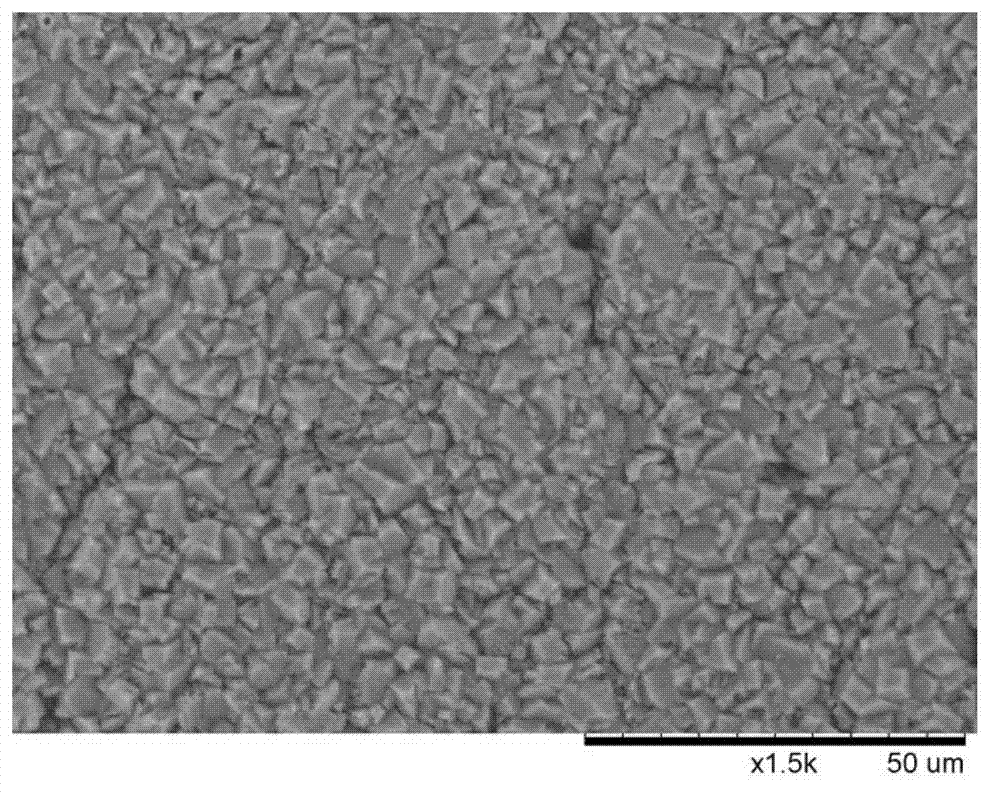

[0039] The steps in this embodiment are basically the same as in Example 1, except that in step (3), before electrodeposition, 20% toluene additive of ionic liquid volume is added in the plating solution, and the plating solution is stirred for a period of time to ensure that The two are mixed evenly.

[0040] Compared with Example 1 of the coating obtained, the microscopic appearance of the coating becomes more compact, and the crystal grains of the coating become smaller, as attached figure 2 shown. The corrosion resistance of the coating is also improved compared to Example 1, and the salt spray test time has reached 240 hours.

Embodiment 3

[0042] The steps in this example are basically the same as in Example 1, except that in step (1), 1-ethyl-3-methylimidazole chloride (EMIC) is used instead of BMIC in Example 1. Compared with the ionic liquid in Example 1, the conductivity of this ionic liquid is reduced, and the voltage under the same current is increased during electrodeposition. The appearance and corrosion resistance of the Al protective coating obtained by electrodeposition are reduced relative to Example 1, and the salt spray test time is 120 hours

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com