Scroll compressor

A scroll compressor and scroll technology, which is applied in the field of compressors, can solve problems such as the inability to maintain long-term and stable adhesion, the inability of the structure to have mass balance, and the inability to eliminate eccentric mass, achieving excellent durability and reliability , reduced inertial mass, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

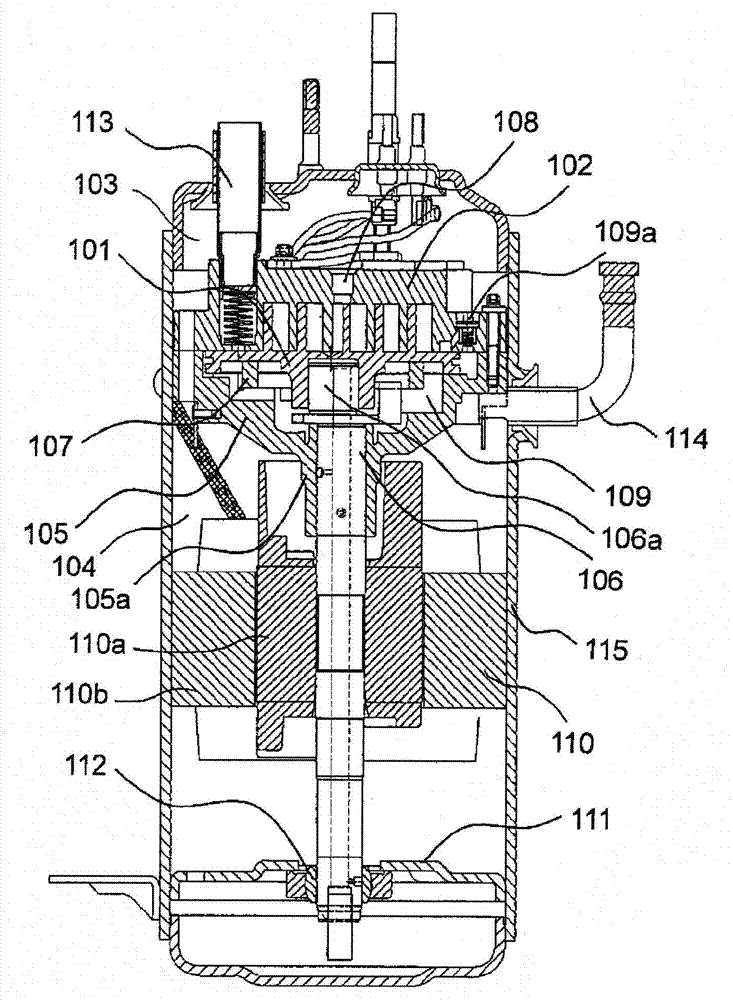

[0031] figure 1 It is a side view showing a schematic structure of the scroll compressor according to Embodiment 1 of the present invention cut along the direction in which the main axis of rotation extends.

[0032] The basic structure of this scroll compressor is known in the past, and the airtight housing (chamber) 115 is provided with a suction port for installing a suction pipe 113 for sucking new refrigerant gas and a nozzle for installing and discharging the refrigerant gas. The discharge port of outlet pipe 114 is installed with the fixed scroll 102 of scroll body at the end side in the airtight casing (chamber) 115, and motor 100 is made of rotor (rotating part) 110a and stator (fixed part) 110b, crankshaft 106 is a rotating main shaft with the rotor 100a of the motor 100 installed in the approximate center, and an orbiting scroll 101 having a scroll body on the opposite side is installed on one end side of the crankshaft 106 in the axial direction via a frame 105, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com