Edible compound stevioside for diabetes patients

A technology of stevioside and compound sweeteners, which is applied in the field of compound sweeteners compounded with stevioside, sugar alcohols and oligosaccharides, which can solve the problem of reducing calorie intake, blood sugar and dental caries index, reducing the amount of sweeteners, etc. problem, to achieve the effect of avoiding gastrointestinal discomfort, good taste and low calorie

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

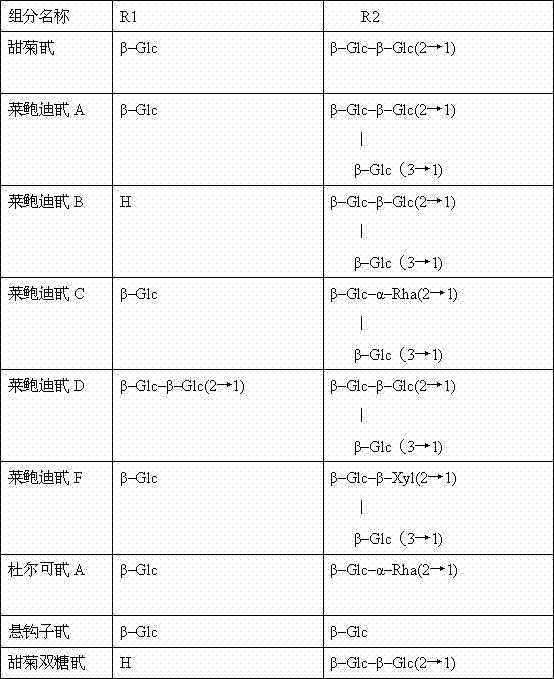

Image

Examples

Embodiment 1

[0040] Take by weighing 43 Kg of erythritol, 10 Kg of stevioside, and 20 Kg of fructooligosaccharide, add erythritol, stevioside, and fructooligosaccharide into the pulverizer to pulverize, and cross 80 mesh sieves; Internally granulate, and then pass through a 20-mesh vibrating sieve; cool the prepared granules and add them to a V-shaped mixer together with the auxiliary material magnesium stearate, mix for 30 minutes, and dry at 65°C; use a 35 punching machine at 20Mpa for tablet molding , adjust the pressure and pellet weight at 0.1 g.

Embodiment 2

[0042] Take by weighing erythritol 50Kg, stevioside 7 Kg, inulin 16Kg, add erythritol, stevioside, inulin into pulverizer and pulverize, cross 100 mesh sieves; Granulate in granulator, Then pass through a 60-mesh vibrating sieve; the prepared granules are cooled and added to a V-shaped blender together with the auxiliary material magnesium stearate, mixed for 45 minutes, dried at 80° C., and directly packed into 150 grams of finished product with a powder packaging machine.

Embodiment 3

[0044]Polysaccharide alcohol 1Kg, strong sweetener 1 Kg, functional oligosaccharide 1Kg, add polysaccharide alcohol, strong sweetener, functional oligosaccharide into the pulverizer and grind, pass through 80 mesh sieve; Internally granulate, and then pass through a 20-mesh vibrating sieve; cool the prepared granules and add them to a V-shaped mixer together with the auxiliary material magnesium stearate, mix for 30 minutes, and dry at 65°C; use a 35 punching machine at 60Mpa for tablet molding , adjust the pressure and pellet weight at 0.08 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com