Preparation method of hydrophobic SiO2 aerogel-activated carbon composite material

A composite material, activated carbon technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of difficult regeneration, high cost, short service life, etc., to achieve good hydrophobicity, good hydrophobic performance, and experimental environment is not complicated. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

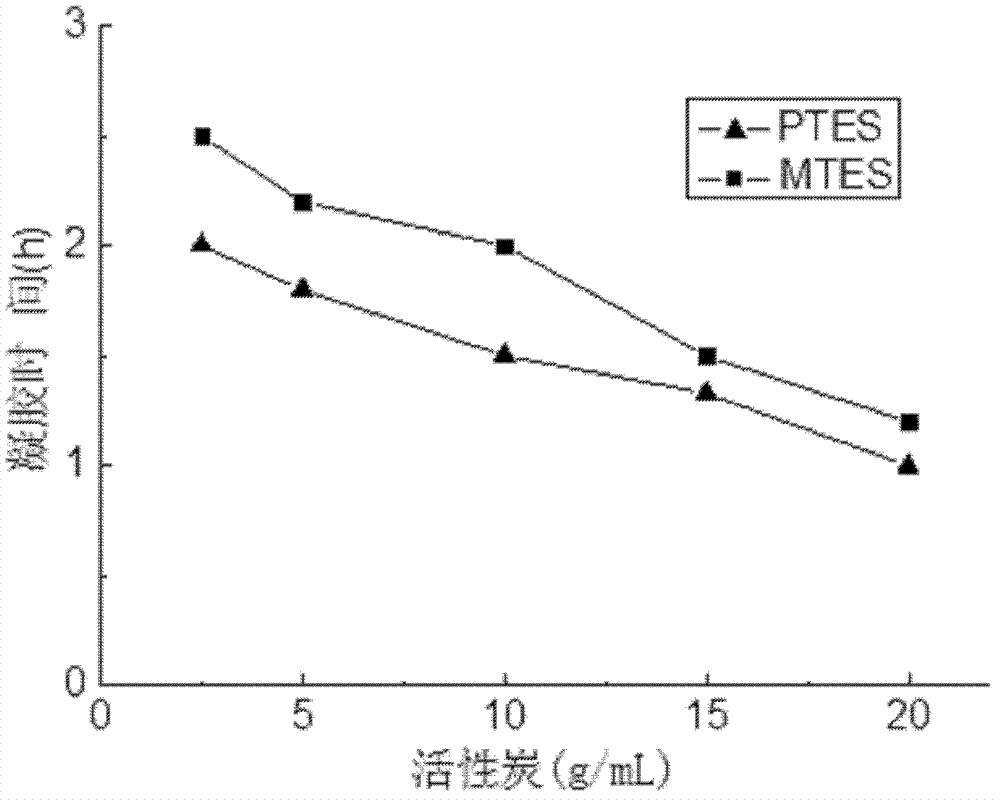

[0023] A mixed solution of 14.7ml tetramethyl orthosilicate, 7.2ml deionized water, 68ml absolute ethanol, 2.4ml phenyltriethoxysilane (PTES) and 0.3ml hydrochloric acid (1mol / L) was used as catalyst at 40°C Under heating and stirring continuously, add ammonia water after 40min to adjust the pH value to 6.5. Continue to stir for 60 minutes to cause polycondensation reaction, and add the solution to 2.5g, 5g, 10g, 15g, and 20g of activated carbon (0.77ml, 1.55ml, 3.1ml, 4.65ml, 6.2ml of activated carbon were used respectively) Hydrochloric acid cleaning, and drying), sonication and standing to form a wet gel. The wet gel was solvent-replaced with absolute ethanol every 12 hours for a total of 3 times. Finally, after drying, the hydrophobic SiO 2 Airgel-activated carbon composites.

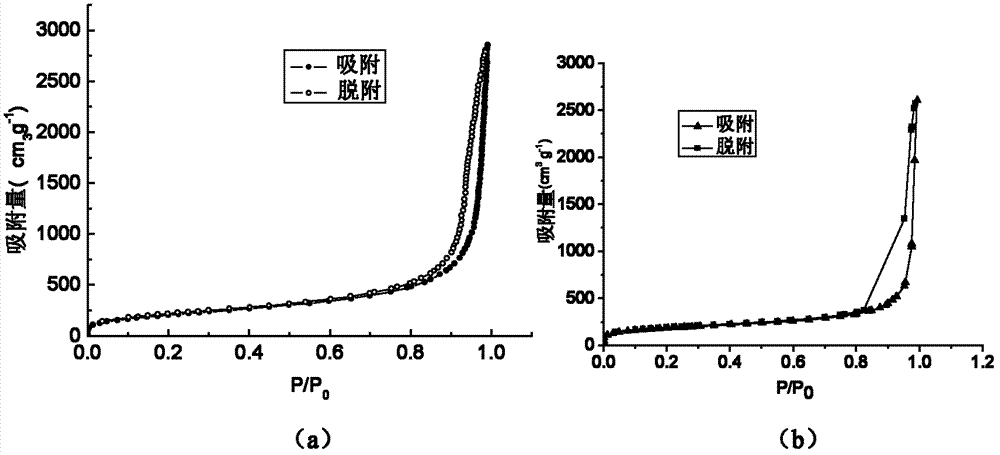

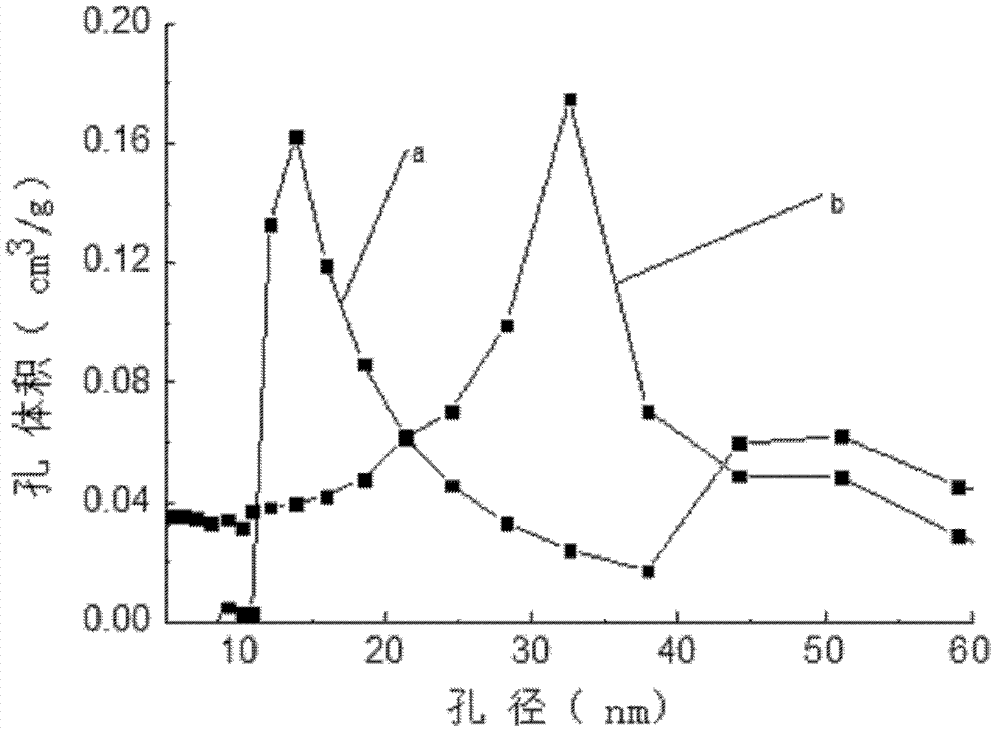

[0024] Modifier phenyltriethoxysilane (PTES) in this example, gac addition is the N of the composite material prepared by 5g 2 Adsorption-desorption isotherm curves such as figure 1 (b) shown. ...

example 2

[0026] Heat the mixed solution of 14.7ml tetramethyl orthosilicate, 14.4ml deionized water, 93ml absolute ethanol, 4.8ml phenyltriethoxysilane (PTES) and 0.8ml acetic acid as catalyst at 50°C and keep stirring After 60 min, sodium hydroxide was added to adjust the pH value to 7. Continue to stir for 40 minutes to make polycondensation reaction occur, and add the solution to 2.5g, 5g, 10g, 15g, and 20g of activated carbon that have been weighed in advance (wherein activated carbon uses 7.7ml, 15.5ml, 31.0ml, 46.5ml, 62.0ml Hydrochloric acid cleaning, and drying), after sonication, stand to form a wet gel. The wet gel was replaced with absolute ethanol for solvent replacement every 24 hours for a total of 5 times. Finally, after drying, the hydrophobic SiO 2 Airgel-activated carbon composites.

example 3

[0028] A mixed solution of 14.7ml of tetramethyl orthosilicate, 7.2ml of deionized water, 68ml of absolute ethanol, 6ml of methyltriethoxysilane (MTES) and 0.5ml (1mol / L) of hydrochloric acid as a catalyst was at 60°C Heating and stirring continuously, after 60 min, potassium hydroxide was added to adjust the pH value to 7.5. Continue to stir for 60min to make it undergo polycondensation reaction, add the solution to be weighed in advance and be respectively in 2.5g, 5g, 10g, 15g, 20g gac (wherein gac is cleaned with hydrochloric acid of 68ml, 135ml, 270ml, 405ml, 540ml respectively, and drying), and left to form a wet gel after ultrasonication. The wet gel was replaced with absolute ethanol for solvent replacement every 12 hours for a total of 8 times. Finally, after drying, the hydrophobic SiO 2 Airgel-activated carbon composites.

[0029] Modifier methyltriethoxysilane (MTES) and gac addition in this example are the N of the composite material prepared by 5g 2 Adsorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com