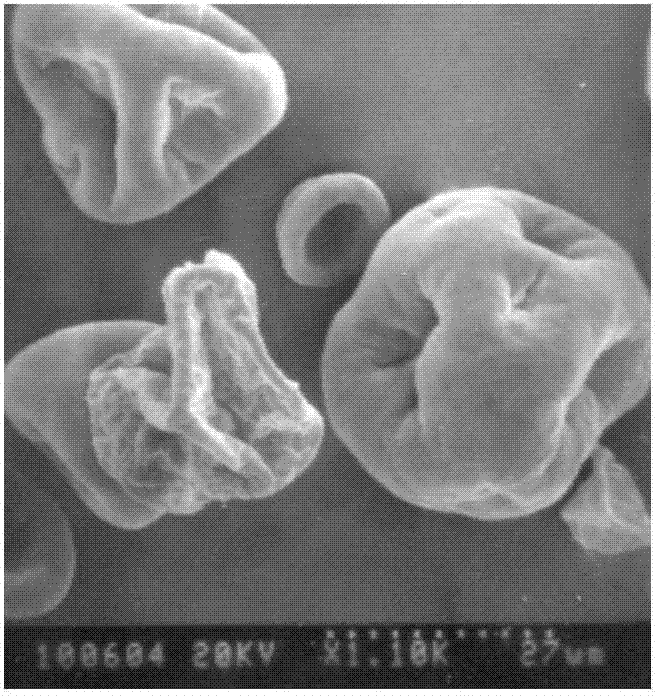

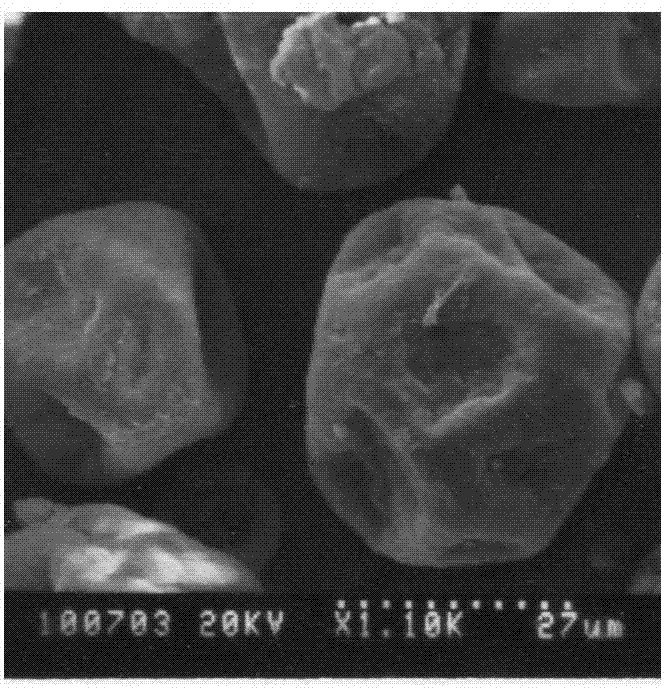

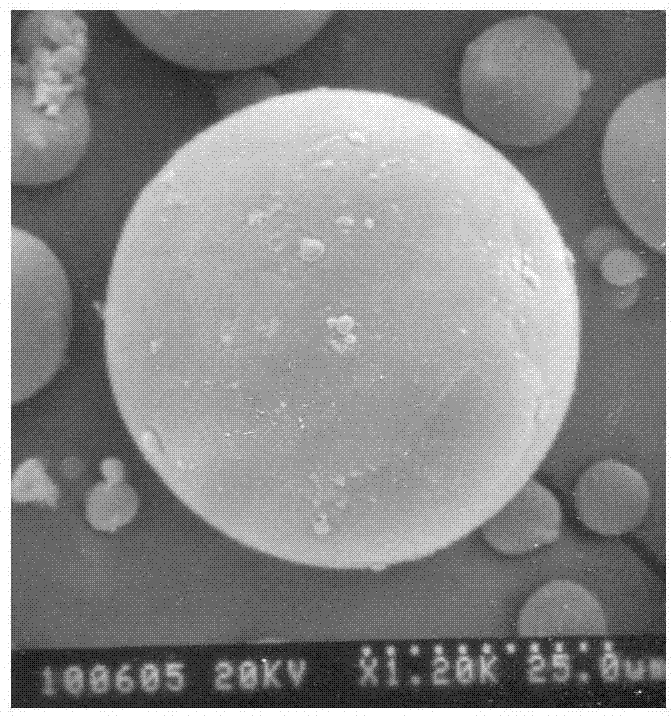

Closely spherical blending resin of vinyl chloride-vinyl acetate copolymer and preparation method thereof

A vinyl acetate copolymer resin and vinyl acetate technology, which is applied in the field of preparing compact spherical vinyl chloride-vinyl acetate copolymer blended resin by suspension method, can solve the problem of surface collapse of vinyl chloride-vinyl acetate copolymer blended resin particles, Unable to prepare vinyl chloride-vinyl acetate copolymer blended resin, internal structure is not tight, etc., to achieve the effect of shortening the plasticizing time, fine particle size, and compact particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 93kg vinyl chloride monomer, 7kg vinyl acetate, 0.3kg initiator (tert-butyl peroxyneodecanoate), 0.2kg sizing agent (sodium sulfide), 0.012kg pH regulator (sodium bicarbonate), 0.15kg dispersant (hydroxypropyl methylcellulose and gelatin), 0.026kg dispersing aid (sodium lauryl sulfate), 200kg desalted water, 0.012kg terminator (acetone thiosemicarbazone).

[0047] Add initiator, dispersant, dispersing aid, sizing agent, desalted water, and pH adjuster to the polymerization kettle, vacuumize after nitrogen pressure test, add 70kg of vinyl chloride monomer, stir, heat up, and carry out polymerization reaction at 62°C. After 2.0 hours of polymerization, when the polymerization conversion rate of vinyl chloride monomer is 30%, the temperature is lowered to 59°C to continue polymerization. After 4.0 hours of polymerization, the polymerization pressure drops, and 23kg of vinyl chloride monomer is added in two times to continue the reaction. The polymerization reaction When th...

Embodiment 2

[0050] 80kg vinyl chloride monomer, 20kg vinyl acetate, 0.35kg initiator (bis-(2-ethylhexyl peroxydicarbonate), tert-butyl peroxyneodecanoate or bis-(3,5,5 -trimethylhexanoyl)), 0.15kg granulator (sodium sulfide), 0.012kg pH regulator (ammonium bicarbonate), 0.17kg dispersant (gelatin), 0.026kg dispersant (cetyl alcohol), 200kg desalination Water, 0.012kg terminator (acetone thiosemicarbazone).

[0051] Add initiator, dispersant, dispersing aid, sizing agent, desalted water, and pH adjuster to the polymerization kettle, vacuumize after nitrogen pressure test, add 70kg of vinyl chloride monomer, stir, heat up, and carry out polymerization reaction at 61.5°C. After 2.0 hours of polymerization, when the polymerization conversion rate of vinyl chloride monomer is 50%, lower the temperature to 58°C and continue polymerization. After 3.5 hours of polymerization, the polymerization pressure drops. After falling (the drop value is about 0.15Mpa), add a terminator to stop the reaction...

Embodiment 3

[0054] 90kg vinyl chloride monomer, 10kg vinyl acetate, 0.3kg initiator (tert-butyl peroxyneodecanoate), 0.2kg sizing agent (sodium sulfide), 0.012kg pH regulator (sodium bicarbonate), 0.015kg dispersant (Hydroxypropylmethylcellulose and gelatin), 0.026kg dispersing aid (sodium lauryl sulfate), 200kg desalted water, 0.012kg terminator (bisphenol A).

[0055] Add initiator, dispersant, dispersing aid, sizing agent, desalted water, and pH adjuster to the polymerization kettle, vacuumize after nitrogen pressure test, add 70kg of vinyl chloride monomer, stir, heat up, and carry out polymerization reaction at 61.5°C. After 2.0 hours of polymerization, when the polymerization conversion rate of vinyl chloride monomer is 40%, the temperature is lowered to 59°C to continue polymerization. After 3.7 hours of polymerization, the polymerization pressure drops. Add 20kg of vinyl chloride monomer to continue the reaction, and the polymerization pressure drops again. (the drop value is abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com