Method for improving dispersity of sodium benzoate nucleating agent in polypropylene

A technology of sodium benzoate and polypropylene, which is applied in the field of improving the effect of sodium benzoate nucleating agent, can solve the problems of not improving the dispersibility of sodium benzoate, poor compatibility and dispersibility, affecting dispersibility, etc., and achieves low price and improved resistance. Impact properties, the effect of increasing the crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

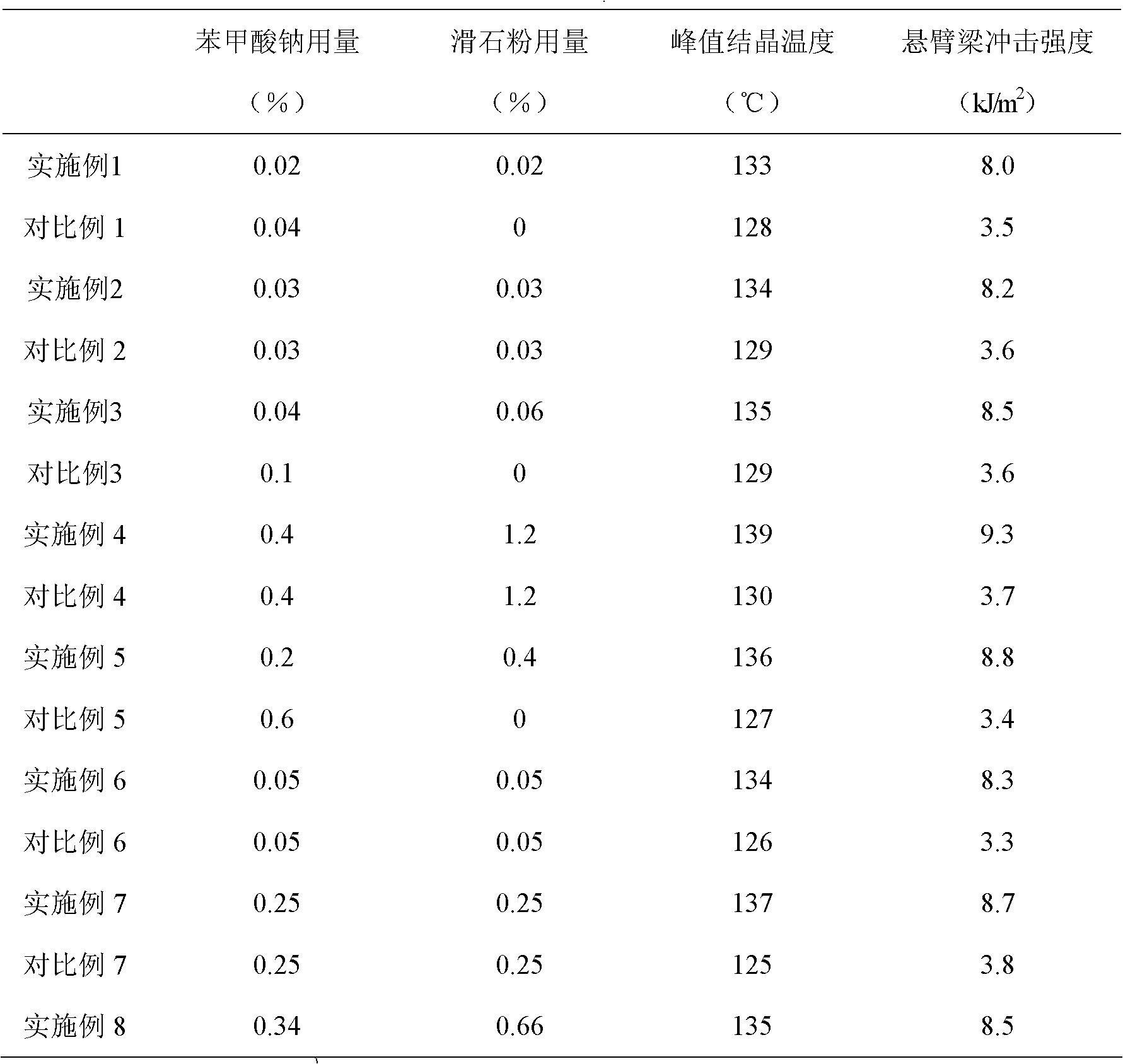

Embodiment 1

[0025] Sodium benzoate powder 25 g is dissolved in 75 g water at 25 ℃ and is made into the aqueous solution of 25% concentration, then the sodium benzoate aqueous solution that prepares is mixed with 25 g talcum powder (2500 orders), wherein talcum powder and sodium benzoate solid The weight ratio is 1:1. Then the sodium benzoate / talcum powder mixture was dried at normal pressure at 120°C, and finally 2g of the dried sodium benzoate / talc powder mixture and 5 kg of polypropylene resin T38F were melted and mixed uniformly at 220°C in a twin-screw extruder and granulated, followed by performance testing. Wherein the sodium benzoate / talcum powder mixture consumption is 0.04%.

Embodiment 2

[0027] Sodium benzoate powder 25g is dissolved in 100g water at 25 ℃ and is made into the aqueous solution of 20% concentration, then the sodium benzoate aqueous solution that prepares is mixed with 25g talcum powder (3000 orders), wherein the weight ratio of talcum powder and sodium benzoate solid is 1:1. Then the sodium benzoate / talcum powder mixture was dried at normal pressure at 120°C, and finally 3 g of the dried sodium benzoate / talc powder mixture and 5 kg of polypropylene resin T38F were melted and mixed uniformly at 220°C in a twin-screw extruder and granulated, followed by performance testing. Wherein the sodium benzoate / talcum powder mixture consumption is 0.06%.

Embodiment 3

[0029] Sodium benzoate powder 25g is dissolved in 50g water at 25 ℃ and is made into the aqueous solution of 33% concentration, then the sodium benzoate aqueous solution that prepares is mixed with 50g talcum powder (5000 orders), wherein the weight ratio of talcum powder and sodium benzoate solid is 2:1. Then the sodium benzoate / talcum powder mixture was dried at normal pressure at 120°C, and finally 5 g of the dried sodium benzoate / talc powder mixture and 5 kg of polypropylene resin T38F were melted and mixed uniformly at 220°C in a twin-screw extruder and granulated, followed by performance testing. Wherein the sodium benzoate / talcum powder mixture consumption is 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| izod impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com