Frame sealing adhesive, preparation method thereof, and preparation method of liquid crystal display panel

A liquid crystal panel and frame sealing adhesive technology, which is applied in the direction of adhesives, optics, non-polymer adhesive additives, etc., can solve the problems of poor quality of liquid crystal display, slow curing speed of epoxy resin, and reduced curing degree, so as to improve the quality of liquid crystal Display effect, avoid poor thermal conductivity, and improve curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation of frame sealant

[0050] In the embodiment of the preparation method of the frame sealant, a frame sealant capable of efficiently and uniformly sealing the liquid crystal panel is prepared mainly by adding a certain proportion of microwave absorber on the basis of the existing frame sealant. Therefore, this implementation An example of a frame sealant mainly includes: epoxy resin, acrylate, glass fiber, metal conductive ball, and a certain proportion of microwave absorber. Wherein, the microwave absorbing agent added is mainly used for absorbing microwave heat when microwave is applied, so as to cure the sealant.

[0051] It should be noted that the certain ratio refers to the percentage by weight of the microwave absorber in the sealant. Generally, the content of the microwave absorber is in the range of 1% to 8%. , The content range of microwave absorber is 2%~5%. When the content of the microwave absorber is 2%, the microwave absorber usuall...

Embodiment 2

[0058] Example 2: Using frame sealant

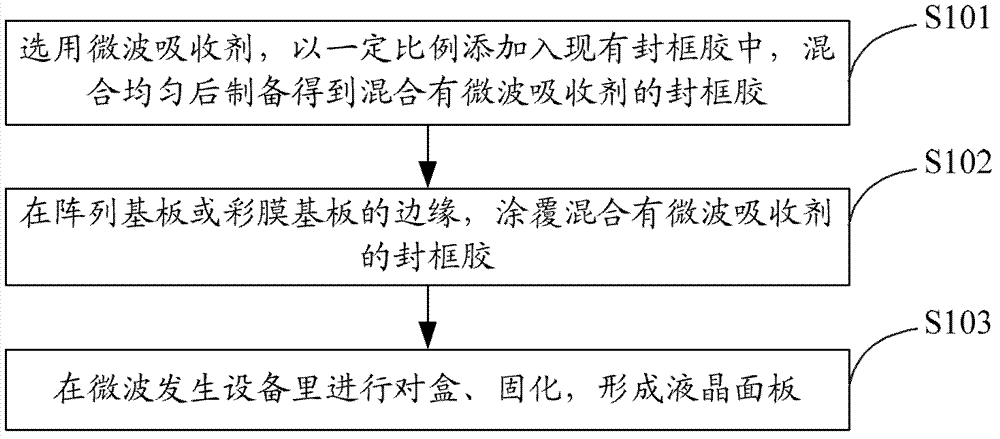

[0059] Such as image 3 As shown, it shows an embodiment of a method for preparing and using a sealant for sealing a liquid crystal panel. Combine below image 3 , explain the curing method of this embodiment using the prepared sealant.

[0060] A method for preparing and using a frame sealant provided in this embodiment includes the following steps:

[0061] S101: Select a microwave absorber, add the selected microwave absorber into the existing frame sealant in a certain proportion, and mix evenly to prepare a frame sealer mixed with the microwave absorber.

[0062] In this step, a microwave absorber is mixed in the frame sealant, so that the frame sealant becomes a microwave absorbing material. Here, according to the actual situation of the liquid crystal panel to be sealed, such as the use environment of the liquid crystal panel, the degree of sealing, the specific curing requirements such as curing aging, etc., the microwave abs...

Embodiment 3

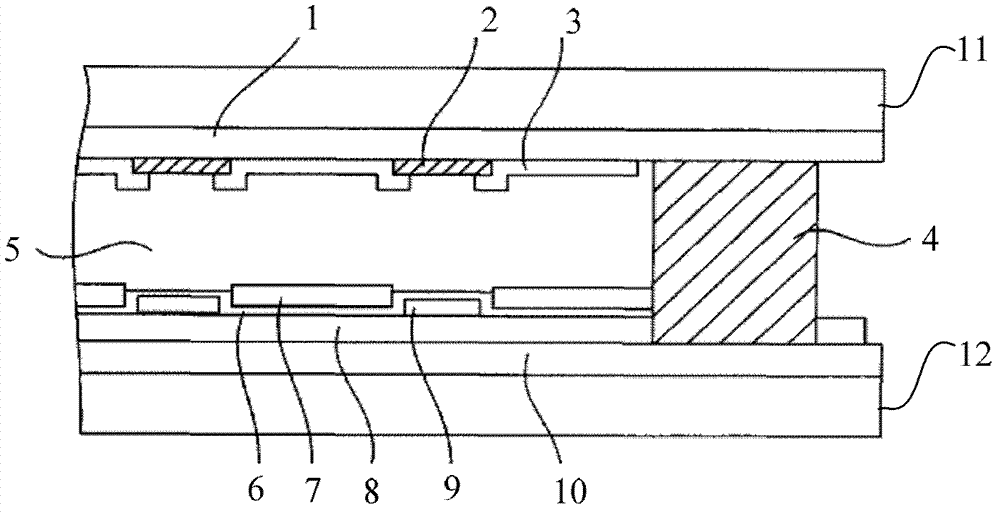

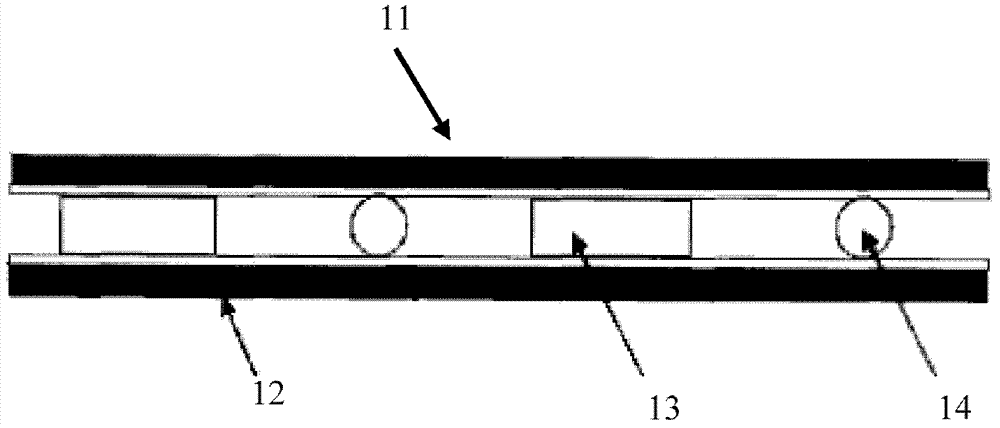

[0069] Embodiment 3: Preparation of liquid crystal panel

[0070] The present invention also provides a method for preparing a liquid crystal panel correspondingly, the method comprising:

[0071] Using the sealant prepared in the preceding Example 1, according to the method of using the sealant in Example 2, apply the prepared sealant on the edge of the array substrate and / or the color filter substrate, and place it in the microwave generating equipment Carry out substrate-to-box and frame-sealing glue curing to form a liquid crystal panel.

[0072] Wherein, the curing of the sealant comprises ultraviolet curing and microwave radiation curing of the sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com