Water-soluble metal antirusting agent and preparation method thereof

A metal rust inhibitor, water-soluble technology, applied in the petroleum industry, base materials, lubricating compositions, etc., can solve the problems of high cost, serious, environmental pollution, etc., achieve good anti-wear and anti-corrosion performance, save energy , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

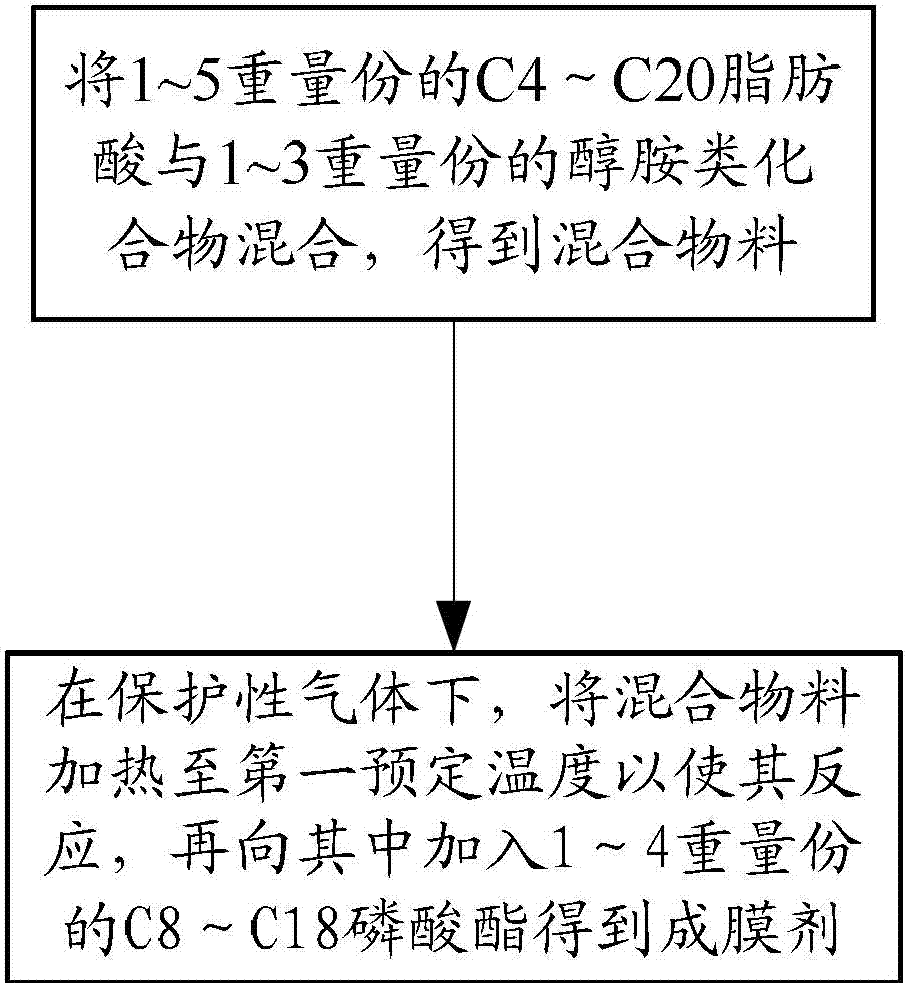

[0052] Specifically, the preparation method of the water-soluble metal antirust agent involved in the present invention comprises the following steps:

[0053] a) mixing 1-5 parts by weight of C4-C20 fatty acids with 1-3 parts by weight of alcohol amine compounds to obtain a mixed material;

[0054] b) Under protective gas, heating the mixed material to a first predetermined temperature to make it react, and then adding 1-4 parts by weight of the C8-C18 phosphoric acid ester therein to obtain the film-forming agent.

[0055] Thus, the film-forming agent can be prepared through a simple preparation process, and the film-forming agent can be attached to the metal surface, so that the water-soluble metal antirust agent has better wear resistance and antirust performance.

[0056] With regard to step a), it should be understood that there is no special limitation on the mixing method of the C4-C20 fatty acid and the alcohol amine compound, as long as the C4-C20 fatty acid and the ...

Embodiment 1

[0066] Mix 1-5 parts of naphthenic acid and 1-3 parts of diisopropanolamine in a reaction kettle, under nitrogen protection, raise the temperature to 100-160°C, after 50 minutes, add 1-4 parts of lauric acid phosphate polyoxyethylene Ether, 1-3 parts of 1-decyl-3 methylimidazole borate compound, react for 30 minutes to prepare water-soluble metal rust inhibitor.

Embodiment 2

[0068] Mix 1-5 parts of sebacic acid and 1-3 parts of diisopropanolamine in a reaction kettle, under nitrogen protection, heat up to 100-160°C, after 50 minutes, add 1-4 parts of oleic acid phosphate polyoxygen Vinyl ether and 1-3 parts of 1-decyl-3 methylimidazole borate compound are reacted for 30 minutes to prepare a water-soluble metal rust inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com