Vacuum fire-resistant glass

A technology of fire-resistant glass and glass, which is applied in the direction of fire prevention, fire doors, parallel glass structures, etc. It can solve the problems of glass vacuum degree reduction, energy saving, insufficient heat insulation effect, affecting the use effect and life of vacuum glass, and achieves a wide range of applications. , Superior performance, good wind pressure resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below in conjunction with accompanying drawing and specific embodiment:

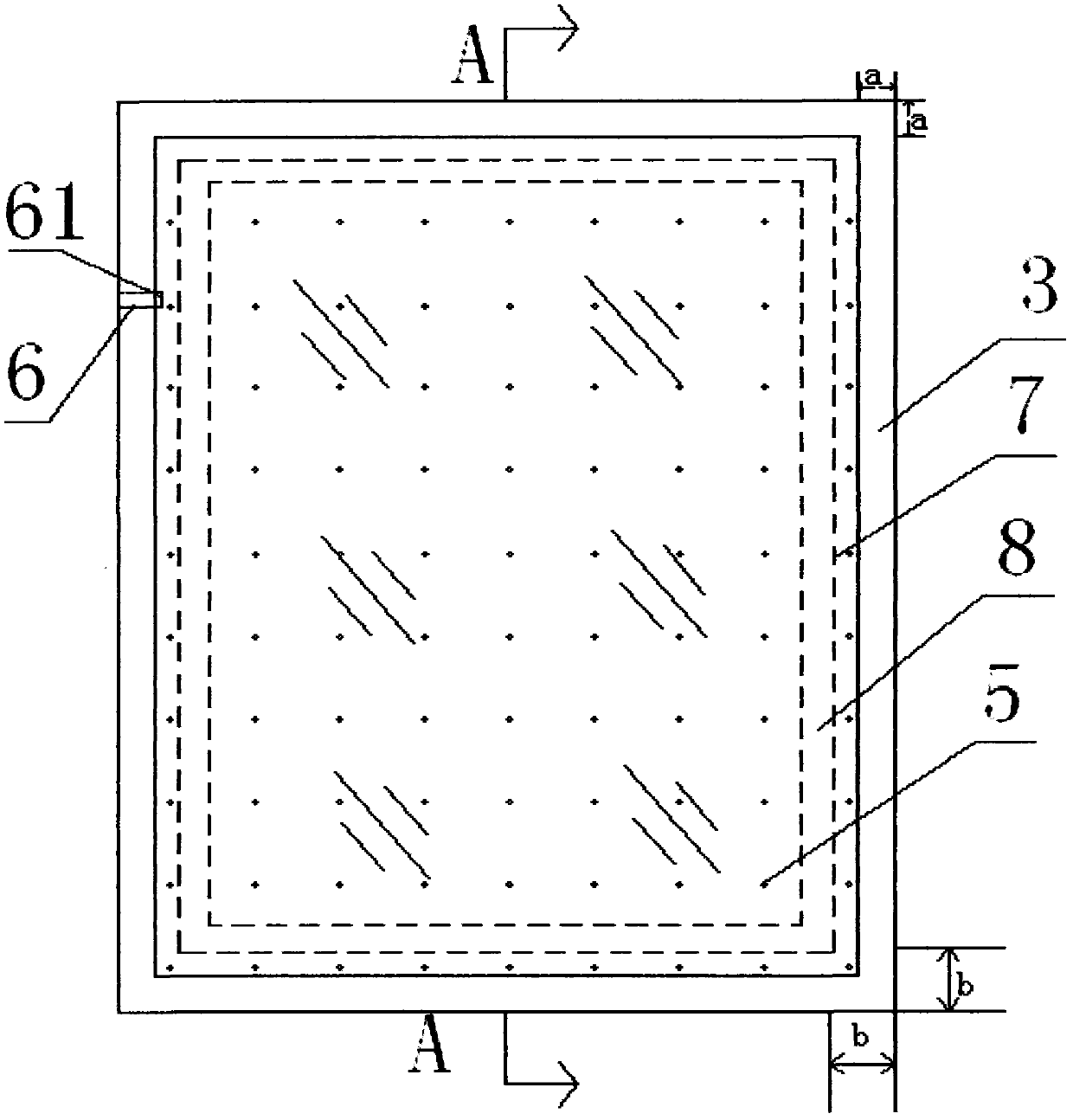

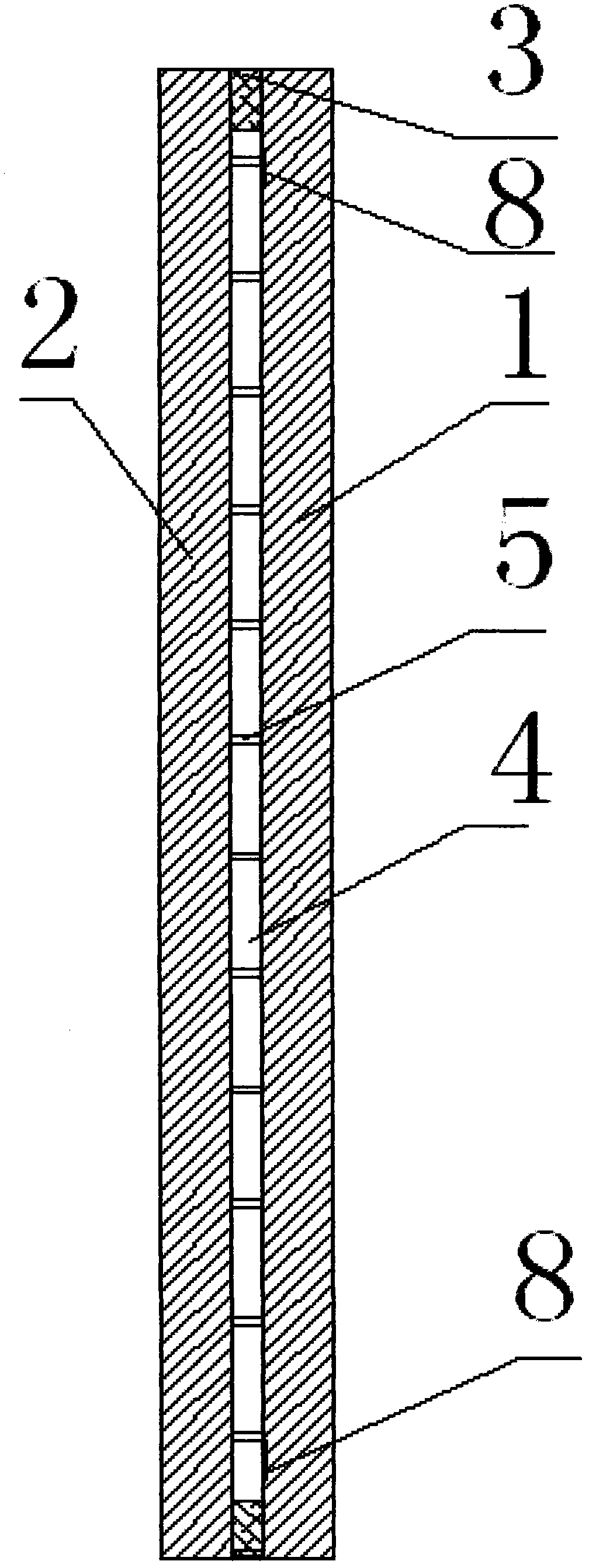

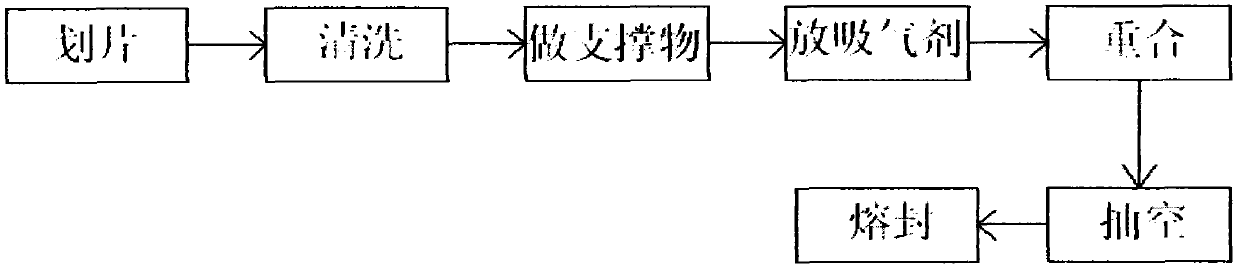

[0032] Such as figure 1 , figure 2 As shown, a vacuum fire-resistant glass includes two parallel glass original sheets 1 and glass original sheets 2, one is set on a circle of fusing seal layer 3 at the edge between the glass original sheets, and the other is arranged between the glass original sheets. The vacuum layer 4 is evenly distributed with supports 5 fixed on the original glass sheet, the thickness of the vacuum layer is 0.15-0.3mm, and the sealing layer 3 between the original glass sheet 1 and the original glass sheet 2 is made of Low-melting point lead glass, the fusing seal layer 3 is provided with an air extraction hole 6, the air extraction hole 6 is provided with a glass tube 61, the support 5 is made of quartz sand, and the inner wall of at least one glass plate in the original glass sheet is A storage space 7 is provided, and a ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com