Waste gas waste heat power generation system of ship diesel generator based on organic Rankine cycle

A diesel generator set and Rankine cycle technology, applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve the problems of increased waste heat of exhaust gas, large design size of steam turbine, large latent heat of vaporization, etc., and achieve the goal of eliminating corrosion damage Possibility, good thermodynamic properties, effect of increasing heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

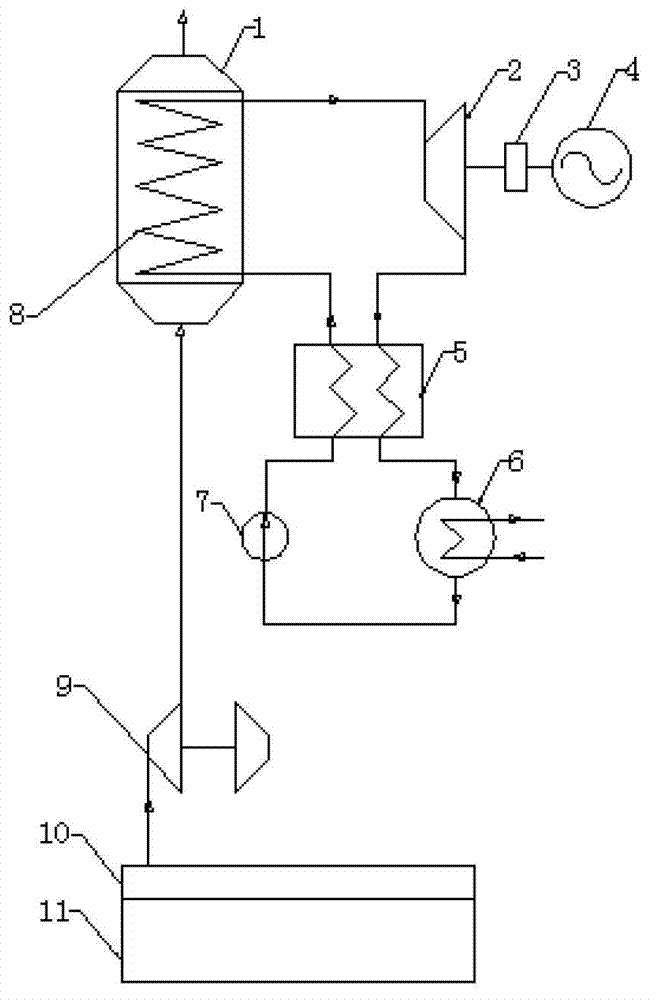

[0022] Such as figure 1 As shown, the exhaust gas produced by the marine diesel generator set 11 first enters the exhaust manifold 10, and then the exhaust gas enters the exhaust turbine (not shown) in the turbocharger 9 from the exhaust manifold 10, and the exhaust gas expands in the exhaust turbine and then enters The present invention is based on the organic Rankine cycle exhaust gas boiler 1 in the exhaust gas waste heat power generation system of the marine diesel g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com