Heat storage combustion type engine

An engine and heat storage technology, applied to combustion engines, engine components, machines/engines, etc., can solve the problem of white or black smoke from the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

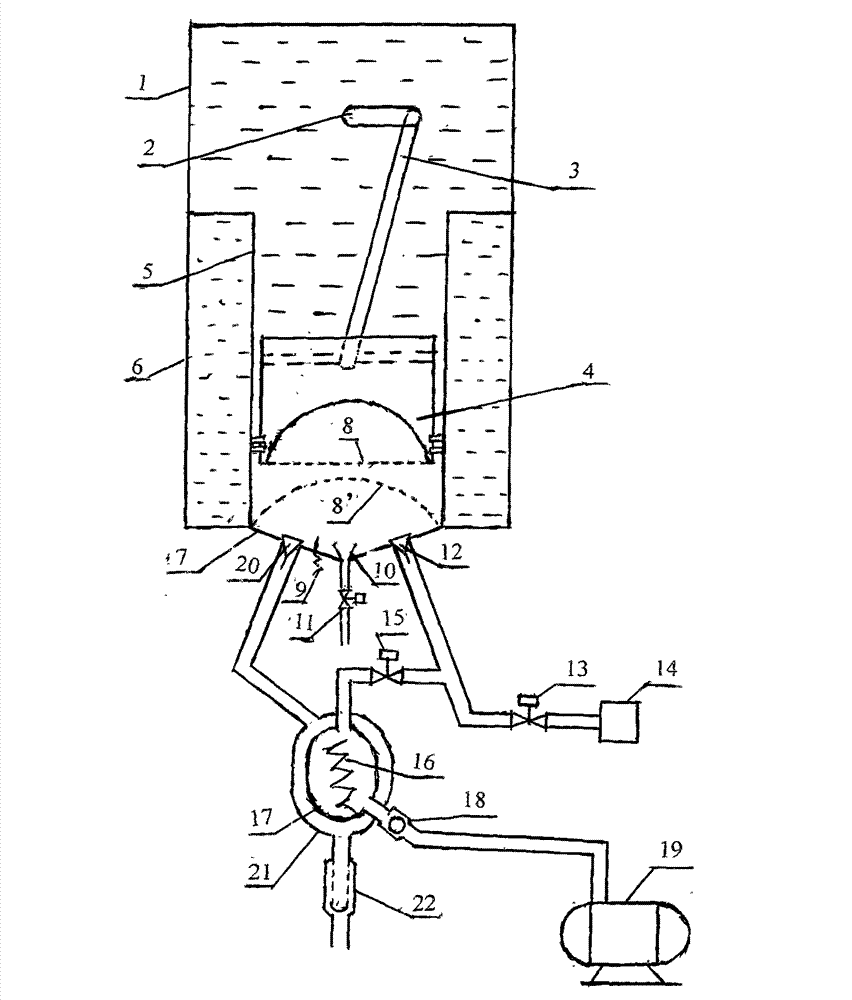

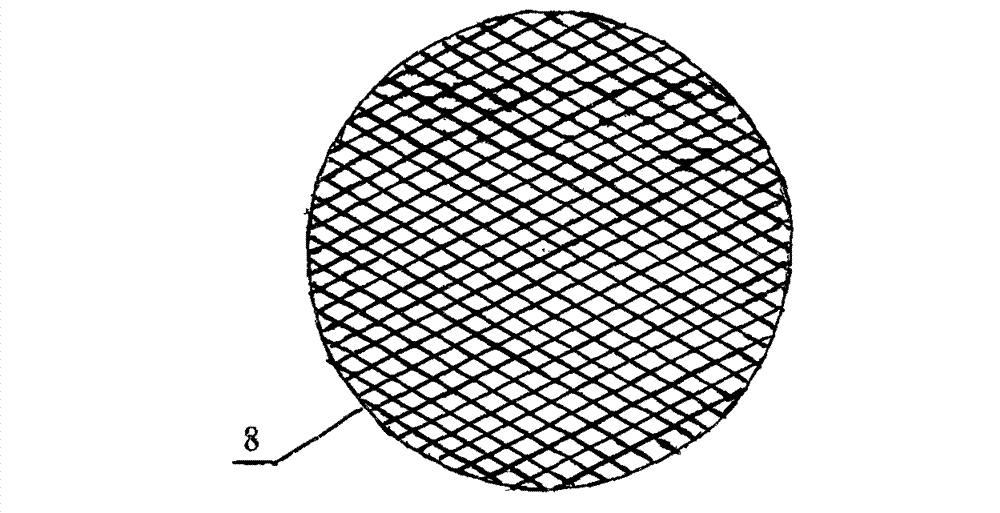

[0009] figure 1 Shown, the thermal storage combustion type engine of the present invention, it is transformed from traditional engine. Its structure mainly includes: crankcase 1, crankshaft 2, crank 3, piston 4, cylinder 5, cylinder liner 6, cylinder head 7, intake valve 12, exhaust valve 20, exhaust pipe 22, air filter 14, nozzle Grease nozzle 10, fuel solenoid valve 11, gasoline engine are equipped with electronic spark plug 9. Organic oil is lubricated in crankcase 1, and coolant cooling cylinder 5 is arranged in cylinder liner 6. Check valve 18, air pressure switch and temperature sensor are housed on compressed air tank 17, and the compressed air that air compressor 19 squeezes out enters compressed air tank 17 after check valve 18. An electric heater 16 is housed in the compressed air storage tank 17 , and an engine exhaust gas heater 21 is externally wrapped in the compressed air storage tank 17 . The air can enter the intake valve 12 after passing through the air fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com