Drying device and design method

A drying equipment and design method technology, applied in the direction of drying solid materials, lighting and heating equipment, heating to dry solid materials, etc., can solve the problems of long heating auxiliary time, boiler safety, high labor intensity, etc., and reduce the heating auxiliary time , high-efficiency heating function, and the effect of improving drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

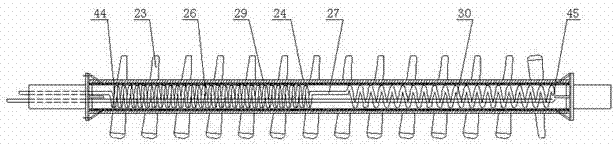

[0028] The drying equipment of the present invention at least includes a stirring propulsion mechanism, a driving mechanism, an inlet and outlet mechanism and an electric control system, and is characterized in that: there is a feed port 22 on one side of the upper part of the stirring propulsion mechanism, and a row is arranged on the other side of the upper part of the stirring propulsion mechanism. The wet tuyere, one side of the stirring propulsion mechanism is also connected with the drive mechanism transmission, the stirring feeder 21 of the stirring propulsion mechanism has an electromagnetic heating transmission stirring device, and the electromagnetic heating transmission stirring device includes an electromagnetic paddle hollow shaft 24, an electromagnetic paddle hollow shaft Inside 24 is an electromagnetic induction coil composed of a wound spiral hollow copper tube, and the tube wall of the spiral hollow copper tube is electrically connected with the electromagnetic ...

Embodiment 2

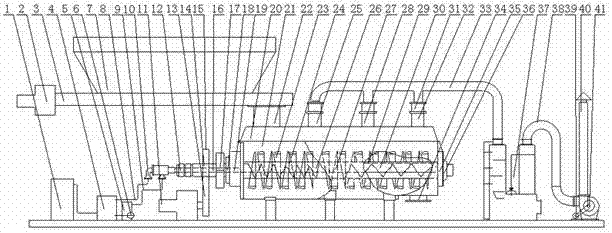

[0031] Such as figure 1 As shown, the top of the stirring bin 21 of the stirring propulsion mechanism in the above-mentioned embodiment is fixed with a bin cover 20, the left side of the bin lid 20 is the feed inlet 22, the right side is the humidity outlet, and the bottom of the right side of the stirring bin 21 is the outlet. The feed port 34, the insulation layer 42 is arranged in the silo wall of the stirring silo 21, and the electromagnetic heating transmission stirring device is arranged in the stirring hopper 21, and the electromagnetic heating transmission stirring device includes a paddle screw blade 23, an electromagnetic paddle hollow shaft 24, an electromagnetic induction Coil, the left and right ends of electromagnetic paddle hollow shaft 24 are respectively connected with front bearing seat 19 and rear bearing seat 35 bearings, and front bearing seat 19 and rear bearing seat 35 are respectively placed in the front bearing cover 18 and the left and right ends of st...

Embodiment 3

[0034] Such as figure 2 As shown, the electromagnetic induction coil in the electromagnetic paddle hollow shaft 24 is composed of a high-temperature electromagnetic induction coil 26, a coil cooling pipe 27, and a low-temperature electromagnetic induction coil 30 to form a multi-temperature zone electromagnetic induction coil. Directly run through the hollow shaft 24 of the electromagnetic paddle and extend to the rear end 45 of the water inlet copper tube, and then spirally wind the hollow copper tube through the section in reverse to form a helical electromagnetic induction coil, which is located on the left side of the hollow shaft 24 of the electromagnetic paddle The number of turns of the spiral electromagnetic induction coil is more to form a high-temperature electromagnetic induction coil 26, and the number of turns of the spiral electromagnetic induction line on the right side of the electromagnetic blade hollow shaft 24 is less to form a low-temperature electromagneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com