Design method for transverse electric/ transverse magnetic (TE/TM) mode separator based on photonic crystal imperfect tape

A technology of photonic crystals and design methods, applied in instruments, light guides, optics, etc., can solve the problems of difficult process, difficult to manufacture, and many polarization crosstalks, and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

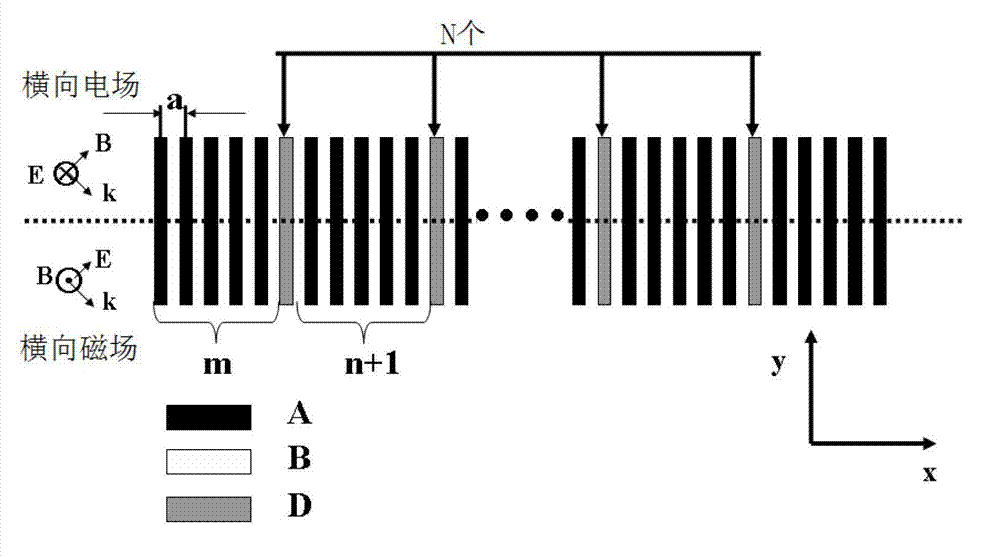

[0025] In order to illustrate the design method of the TE / TM mode splitter, we first take a one-dimensional photonic crystal as an example to illustrate our design process. Such as figure 1 As shown, this one-dimensional photonic crystal is composed of dielectric materials with a dielectric constant of 1 (air) and 13 (such as silicon), and their normalized thickness is 0.5. In it, N defect layers are introduced periodically to form a coupled microcavity waveguide structure, the dielectric constant of the defect layer can be changed between 1 and 13, and the normalized thickness can also be changed between 0.1 and 0.9.

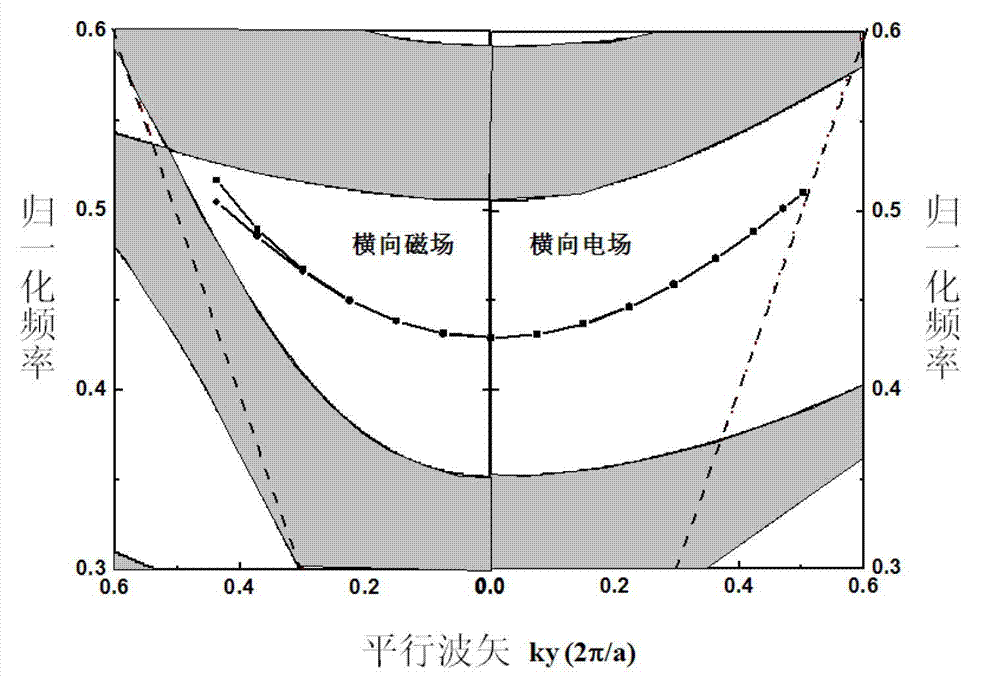

[0026] Here we first choose one situation for detailed discussion, for example, we choose the dielectric constant of the defect layer to be 6, its normalized thickness is 0.5, and the number of defect layers is N=10. It can be obtained from the previous calculation that these defect states will form defect bands in the band gap of the photonic crystal. In ord...

Embodiment 2

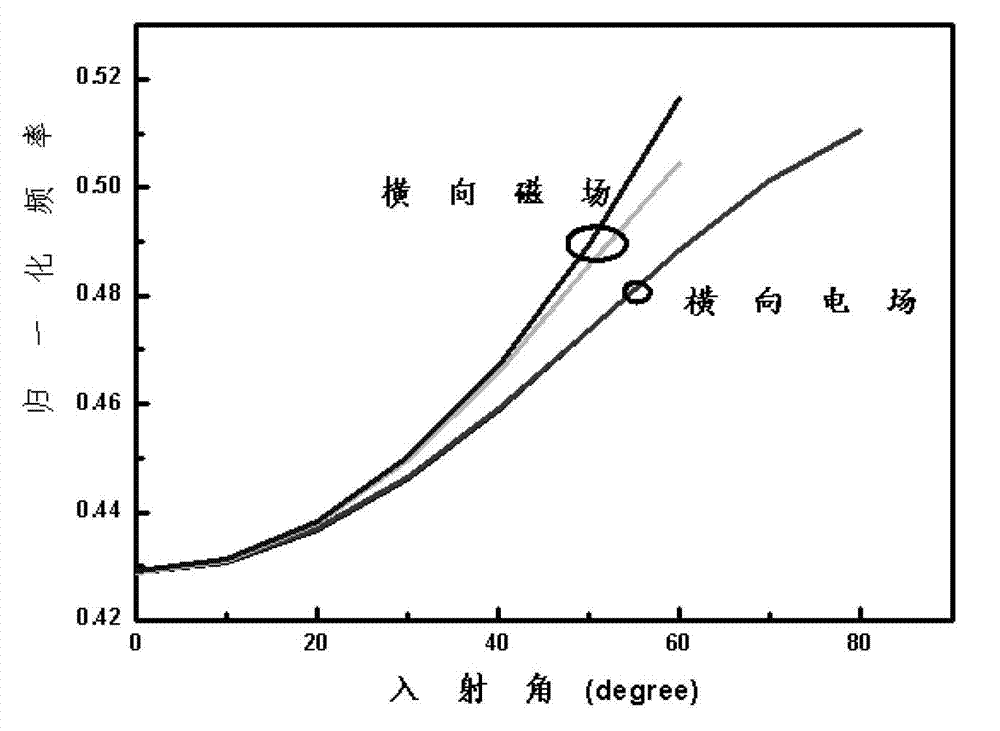

[0028] To illustrate the influence of the parameters of the defect layer on the TE / TM mode separator in more detail, we discuss the properties of different defect layers in detail: when the dielectric constant of the defect layer is 1, similar to the previous discussion process, the coupling can be obtained The minimum splitting angle of the TE / TM defect band of the microcavity waveguide is 17.4. When the dielectric constant of the defect layer is 13, the minimum splitting angle of the TE / TM defect bands of the coupled microcavity waveguide is 8.4. In short, a defect layer with a low dielectric constant requires a larger incident angle to split the TE / TM defect bands. This is due to the fact that the defect layer with a low dielectric constant has poor localization to the electromagnetic field, so that the localization of the electromagnetic field in the TE mode also decreases with the increase of the incident angle, so the defects of the TE and TM modes have the same For exa...

Embodiment 3

[0030]In order to discuss the application of TE / TM mode separators based on photonic crystal defect bands more completely and its special band separation effect, we have studied its physical characteristics in detail, and believe that the defect layer spacing has a great influence on this result, which can be The transmission of the flat-band structure is realized by adjusting the period number n between defective layers. Such as Figure 8 Shown is the photonic crystal coupled waveguide transmission spectrum with the number of defect interlayer cycles n equal to 9, 10 and 11 respectively. It can be found that the defect interlayer cycle number n=10 will have a wide flat band result, which can realize broadband transmission, which will be in It plays an important role in broadband TE / TM mode separators. In order to be practical, we have designed a TE / TM mode separator based on the wavelength of 1550nm in the optical communication band, such as Figure 9 As shown, the electrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com