Powdered oil for replacing oil packet of instant noodles and preparation method thereof

A technology of powdered oil and instant noodles, applied in the field of food science, can solve the problems of easy oxidation and rancidity of oil, high viscosity of oil, poor fluidity, etc., and achieve good solubility, good instant solubility, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

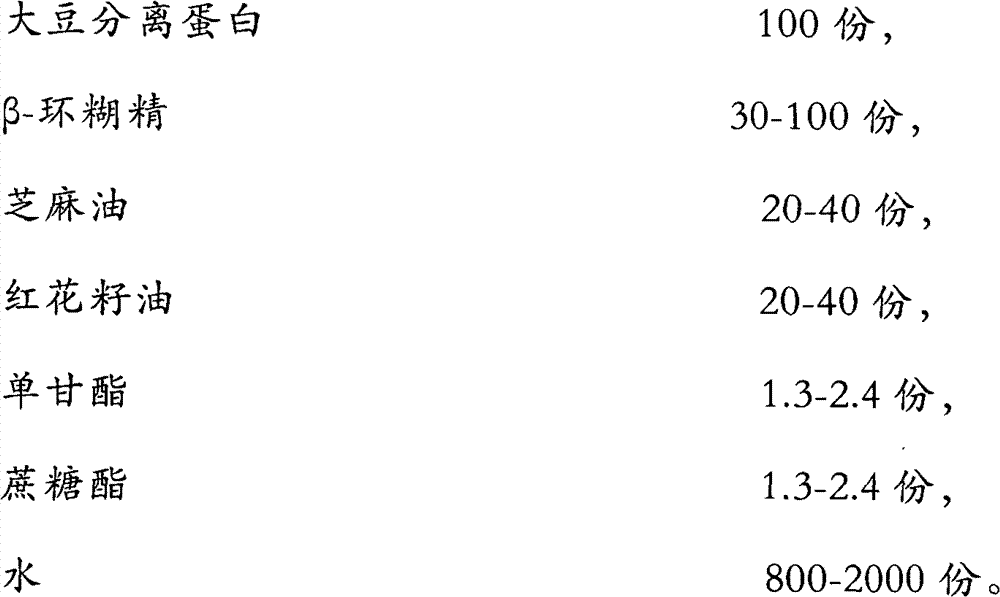

[0020] (1) Get 100Kg soybean protein isolate and β-cyclodextrin (mass ratio 1: 1), disperse them in 750L distilled water, add 2.8Kg of monoglyceride and sucrose ester (mass ratio 1: 1), control the temperature at 50 -60°C, stir with an electric stirrer until fully dissolved, slowly add 40Kg of sesame oil and safflower oil (mass ratio 1:1), and stir evenly.

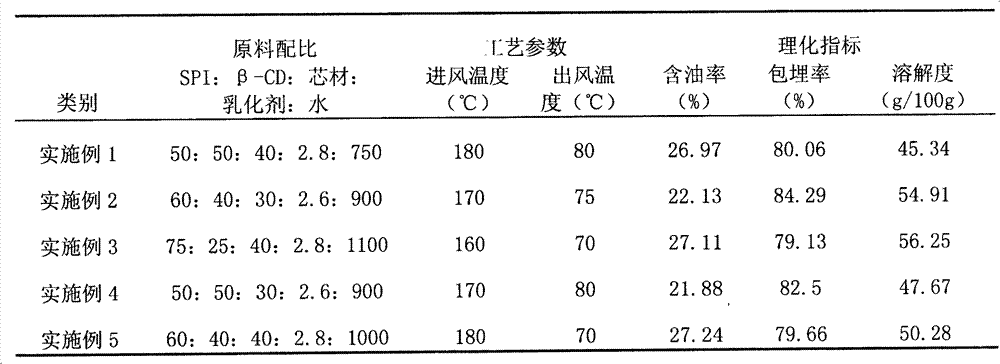

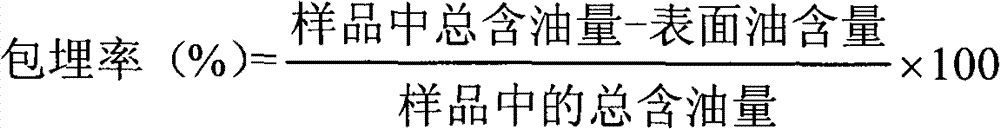

[0021] (2) The emulsion is further emulsified and homogenized, the homogenization pressure is 40Mpa, the time is 15min, the emulsion is spray-dried, the inlet air temperature is 180°C, and the outlet air temperature is 80°C to obtain powdered oil. The oil content, embedding rate and dissolution characteristics of the product are shown in Table 1.

Embodiment 2

[0023] (1) Get 100Kg soybean protein isolate and β-cyclodextrin (mass ratio 3: 2), disperse in 900L distilled water, add 2.6Kg of monoglyceride and sucrose ester (mass ratio 1: 1), control the temperature at 50 -60°C, stir with an electric stirrer until fully dissolved, slowly add 30Kg of sesame oil and safflower oil (mass ratio 1:1), and stir evenly.

[0024] (2) The emulsion is further emulsified and homogenized, the homogenization pressure is 30Mpa, the time is 20min, the emulsion is spray-dried, the inlet air temperature is 170°C, and the outlet air temperature is 75°C to obtain powdered oil. The oil content, embedding rate and dissolution characteristics of the product are shown in Table 1.

Embodiment 3

[0026] (1) Get 100Kg soybean protein isolate and β-cyclodextrin (mass ratio 3: 1), disperse them in 1100L distilled water, add 2.8Kg of monoglyceride and sucrose ester (mass ratio 1: 1), control the temperature at 50 -60°C, stir with an electric stirrer until fully dissolved, slowly add 40Kg of sesame oil and safflower oil (mass ratio 1:1), and stir evenly.

[0027] (2) The emulsion is further emulsified and homogenized, the homogenization pressure is 35Mpa, the time is 10min, the emulsion is spray-dried, the inlet air temperature is 160°C, and the outlet air temperature is 70°C to obtain powdered oil. The oil content, embedding rate and dissolution characteristics of the product are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com