Ultra-fine glass fiber coated substrate and preparation method thereof

A glass fiber and film coating technology, which is applied in the field of film-coated substrates made of ultra-fine glass fiber, can solve the problems of folding resistance, corrosion resistance, water-repellent and oil-repellent substrate and film bonding of glass fiber-coated substrates. The performance indicators cannot fully meet the use requirements, and the glass fiber has poor folding resistance, etc., to achieve the effects of excellent cost performance, improved filtration effect, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

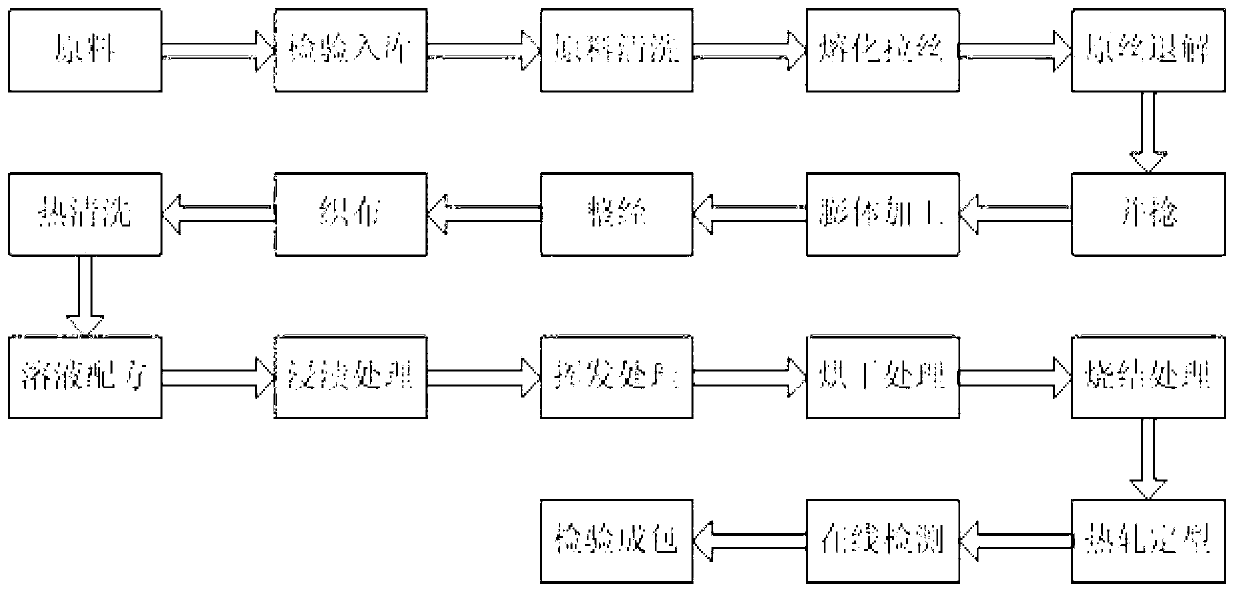

[0027] The high-performance ultra-fine glass fiber expanded film-coated base material and the preparation method thereof of the present invention comprise the following steps:

[0028] 1. After the high-quality raw materials are washed, they are put into a kiln at 1350°C, melted at a high temperature, and passed through a yarn making system to make ultra-fine glass fiber yarn with a single filament diameter of 3.8-5.5 μm. The warp yarn and weft yarn are spun into warp yarn and weft yarn respectively after debonding and twisting. The warp yarn is warped to make a warp beam, and the weft yarn is woven into a 750g / ㎡ glass fiber cloth after being bulked and deformed.

[0029] 2. Heat-clean the woven glass fiber filter cloth of 750g / ㎡, and remove various additives on the surface of the fabric through high temperature, so as to facilitate subsequent processing; the temperature of the heat-cleaning process is 200°C-450°C, and the running speed is 6m / min.

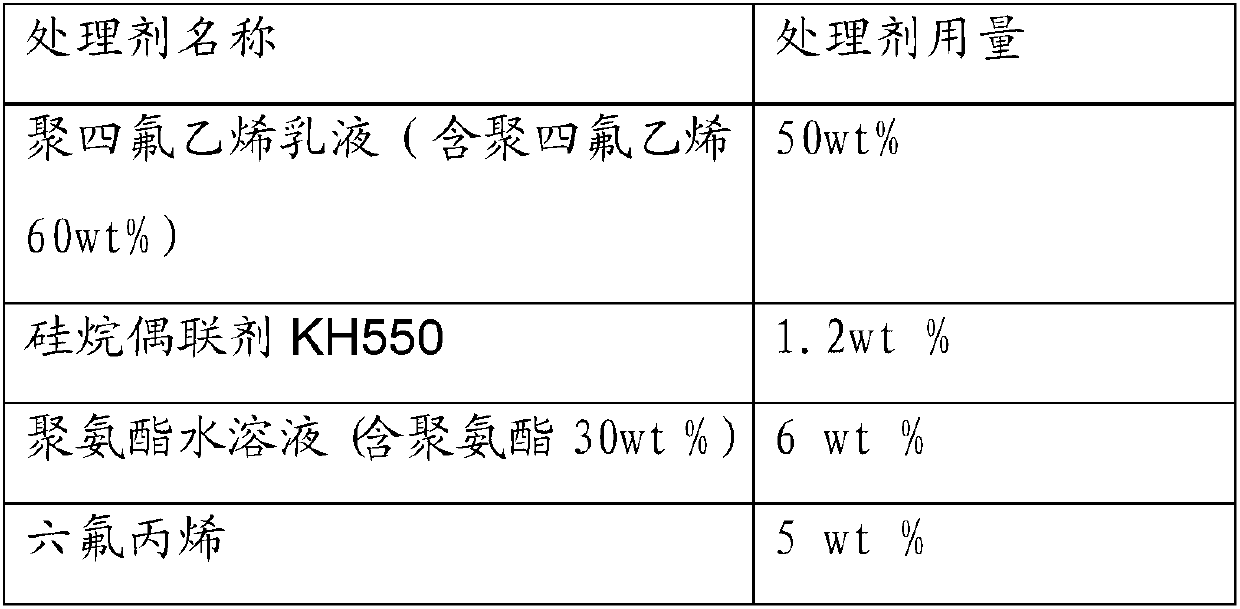

[0030] 3. The cleaned fil...

Embodiment 2

[0037] The high-performance ultra-fine glass fiber expanded film-coated base material and the preparation method thereof of the present invention comprise the following steps:

[0038] 1. After the high-quality raw materials are washed, they are put into a kiln at 1350°C, melted at a high temperature, and passed through a yarn making system to make ultra-fine glass fiber yarn with a single filament diameter of 3.8-5.5 μm. After debonding and twisting, the warp yarn and weft yarn are spun into warp yarn and weft yarn respectively. The warp yarn is warped to make a warp beam, and the weft yarn is woven into a 470g / ㎡ glass fiber cloth after being bulked and deformed.

[0039] 2. Heat-clean the woven glass fiber filter cloth of 470g / ㎡, and remove various additives on the surface of the fabric through high temperature, so as to facilitate subsequent processing; the temperature of the heat-cleaning process is 200°C-450°C, and the running speed is 8m / min.

[0040] 3. The cleaned fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com