Preparation method of hollow mesoporous silica nanoparticle

A technology of mesoporous silicon dioxide and nanoparticles, applied in the direction of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problems of limited drug loading of mesoporous silicon nanoparticles combined with other functional materials, limited use range, etc. Achieve the effect of low price, low density and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

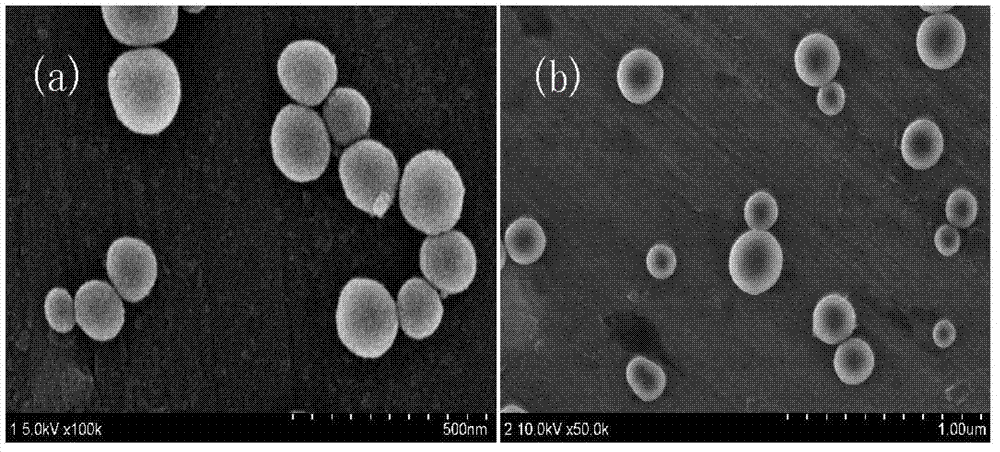

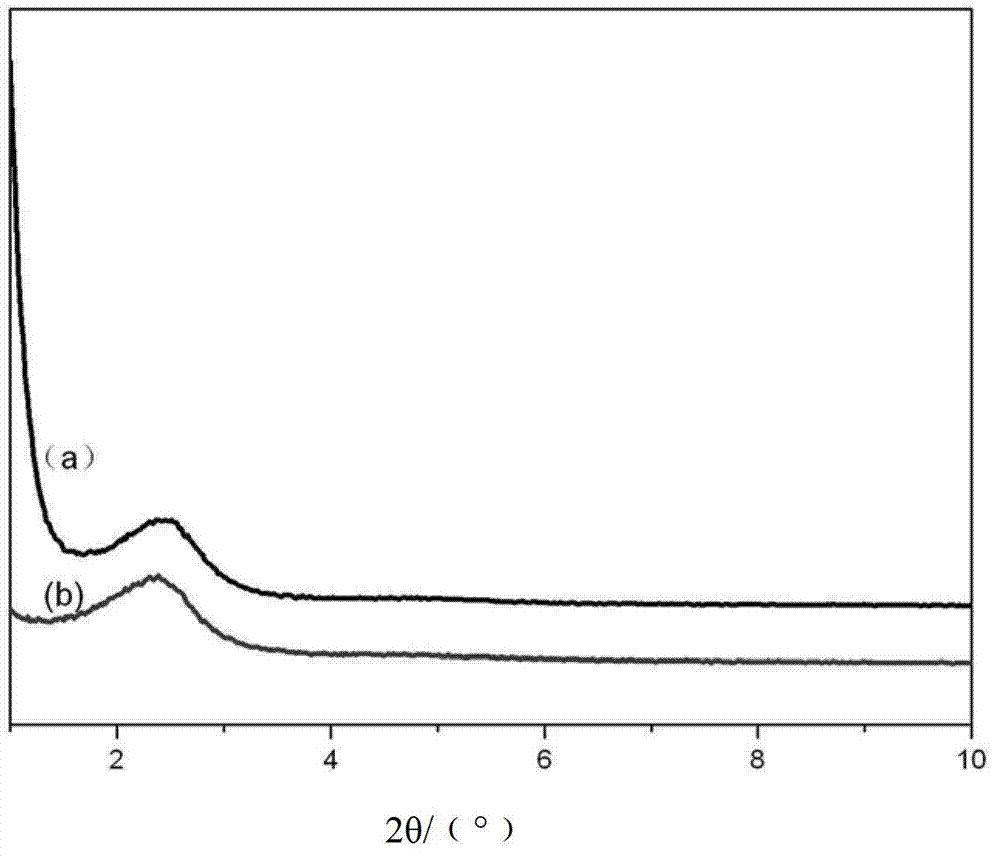

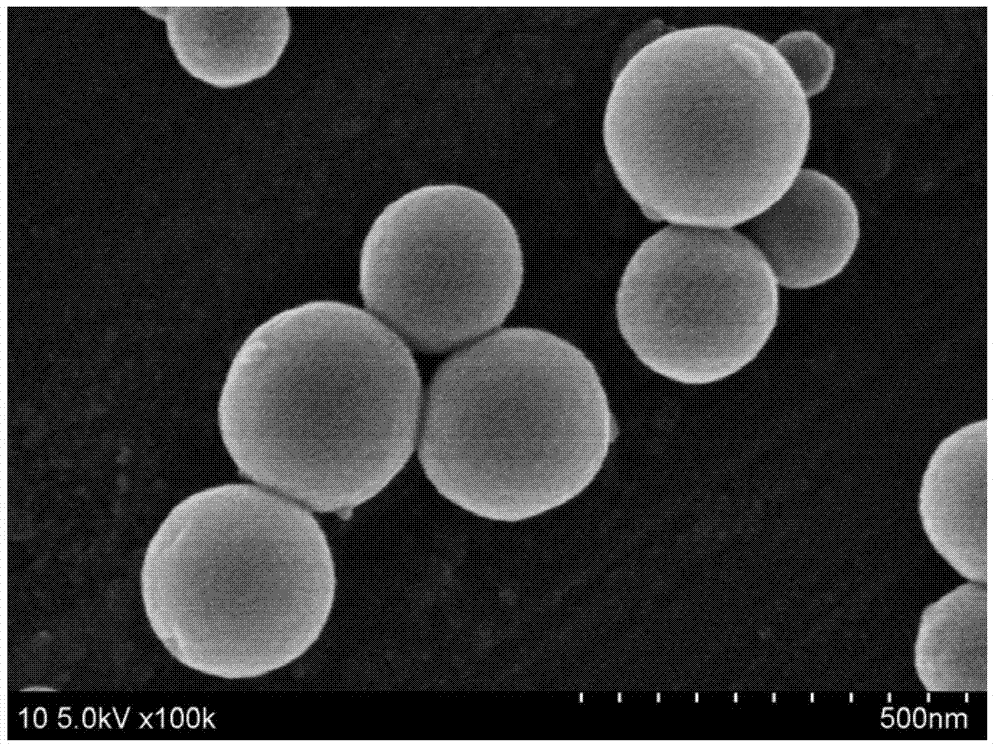

[0029] Amphiphilic polymer PAA 4 -b-PS 34 Preparation of hollow mesoporous silica from aggregates as templates

[0030] (1) Weigh 0.2g cetyltrimethylammonium bromide and dissolve it in 80ml pure water, add 3ml NH under 400r / min stirring condition on a magnetic stirrer 3 ·H 2 O.

[0031] (2) Weigh out 0.08g amphiphilic block polymer PS under 400r / min stirring conditions 34 -b-PAA 4 Dissolve it in 16ml of tetrahydrofuran THF. After it is completely dissolved, add it dropwise to the solution obtained in step (1), continue to stir for 10min under stirring conditions of 400r / min, and dilute with 160ml of absolute ethanol to obtain a dilution.

[0032] (3) Dilute 0.6g (0.603ml) ethyl orthosilicate TEOS in 10ml ethanol, and then add it dropwise to the diluent obtained in step (2), and stir at 400r / min for 24h at room temperature.

[0033] (4) At the end of the reaction, centrifuge, dry the precipitate at 50°C for 1.5h, and then calcinate at 550°C for 6h to obtain hollow mesoporous silicon nan...

Embodiment 2

[0035] Amphiphilic polymer PAA 4 -b-PS 58 Preparation of hollow mesoporous silicon from aggregates as templates

[0036] (1) Weigh 0.2g cetyltrimethylammonium bromide and dissolve it in 80ml pure water, add 3ml NH under 400r / min stirring condition on a magnetic stirrer 3 ·H 2 O.

[0037] (2) Under 400r / min stirring conditions, weigh out 0.1g amphiphilic block polymer PS 58 -b-PAA 4 Dissolve it in 16ml of tetrahydrofuran. After it is completely dissolved, add it dropwise to the solution obtained in step (1), continue to stir for 10min under stirring conditions of 400r / min, and dilute with 160ml of absolute ethanol to obtain a dilution.

[0038] (3) Dilute 0.6g (0.603ml) ethyl orthosilicate TEOS in 10ml ethanol, and then add it dropwise to the diluent obtained in step (2), and stir at 400r / min for 24h at room temperature.

[0039] (4) At the end of the reaction, centrifuge, and dry the precipitate at 50°C for 1.5h, and then calcinate at 550°C for 6h to obtain hollow mesoporous silicon na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com