Magnetic polymer particle, its preparation method and its application

A technology of polymer particles and polymers, applied in chemical instruments and methods, the magnetism of organic materials/organic magnetic materials, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem that the magnetic retention rate needs to be further improved and other problems, to achieve the effect of high magnetic retention rate, good compatibility and strong interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

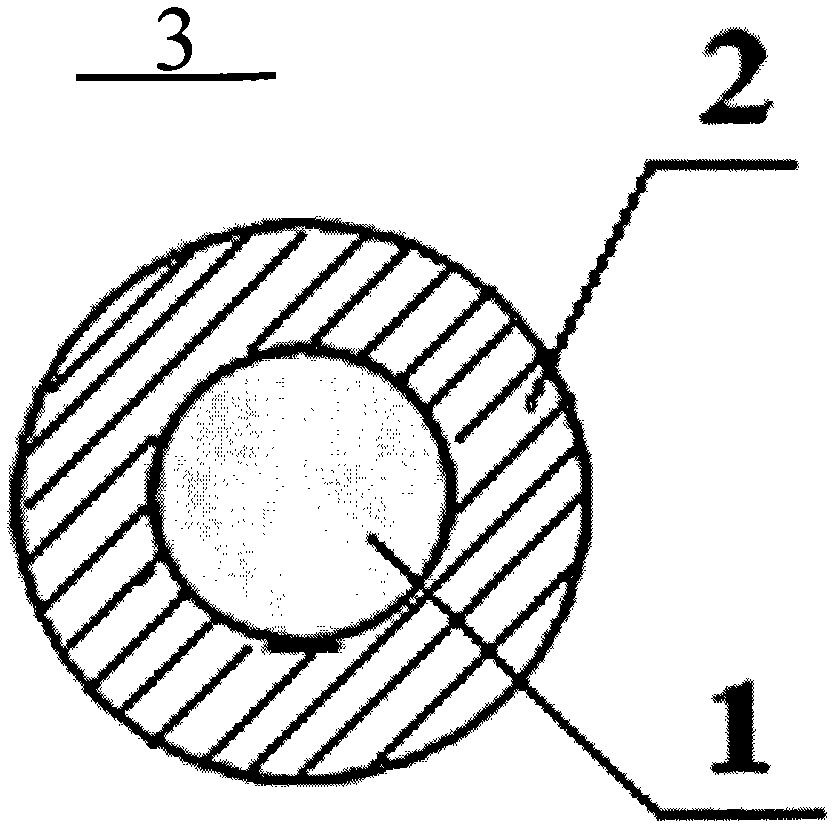

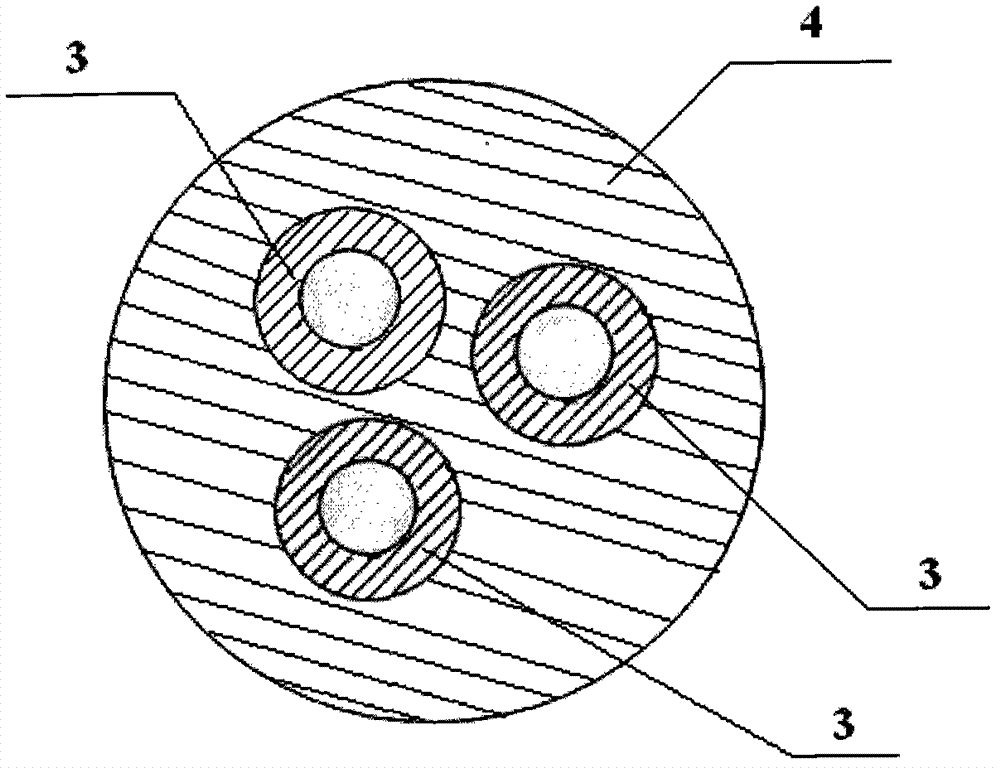

[0030] The present invention also provides a method for preparing magnetic polymer particles, the method comprising: forming a silicon dioxide coating layer on the surface of the magnetic particles to obtain a magnetic core; and embedding the magnetic core in a polymer to obtain Magnetic polymer particles are formed.

[0031] According to the method of the invention, the ratio between the magnetic particles and the silica coating can be varied within a wide range. Preferably, the amount of the magnetic particles and the amount of the silica coating layer are such that the ratio between the average particle diameter of the magnetic particles and the average particle diameter of the obtained magnetic core is preferably 1:1.1-3.5, More preferably 1:1.2-2.5.

[0032] According to the method of the invention, the ratio between the amount of the magnetic core and the amount of the polymer can be varied within wide ranges. Generally, the ratio between the amount of the magnetic cor...

Embodiment 1

[0078] This example is used to illustrate the magnetic polymer particle and its preparation method according to the present invention.

[0079] (1) Add 5g of iron powder with an average particle diameter of 50nm (the specific saturation magnetization is 121emu / g) into the three-necked flask, and then add 200mL of deionized water to the above-mentioned three-necked flask with stirring, followed by adding 20mL of 0.01mol / L of 3-aminopropyltriethoxysilane in water. After stirring for 30 minutes, 55 mL of an aqueous sodium silicate solution with a pH value of 8 and a concentration of 0.2 mol / L was added. After stirring at 75° C. for 24 hours, the resulting solution was centrifuged to obtain a solid component. Then, the obtained solid component was dispersed in a mixed solution of 150 mL of water and ethanol (the volume ratio of water and ethanol was 1:9), and then with stirring, 87 mL of a concentration of 0.2 mol / L was added dropwise to the above solution. An ethanol solution ...

Embodiment 2

[0087] This example is used to illustrate the magnetic polymer particle and its preparation method according to the present invention.

[0088] (1) Add 5g of Fe with an average particle diameter of 20nm in a three-necked flask 3 o 4 powder (the specific saturation magnetization is 78.7emu / g), and then with stirring, add 150mL of a mixture of water and ethanol (the volume ratio of water to ethanol is 1:9) into the above-mentioned three-necked flask, and then add 145mL of 0.2mol The ethanol solution of tetraethyl orthosilicate in / L, the above-mentioned three-neck flask is placed in the ultrasonic disperser and carries out ultrasonic treatment for 10 minutes, and in the solution after ultrasonic treatment along with stirring, drip the ammoniacal liquor that concentration is 25% by weight, make reaction The pH value of the solution was 10±0.2, and the stirring was continued at 35°C for 6h. Finally, solid-liquid separation was carried out, and the obtained solid was washed twice w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com