Highly-flavored liquor production method capable of reducing extruded waste vinasse residual starch

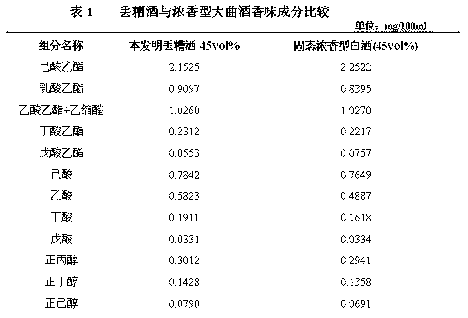

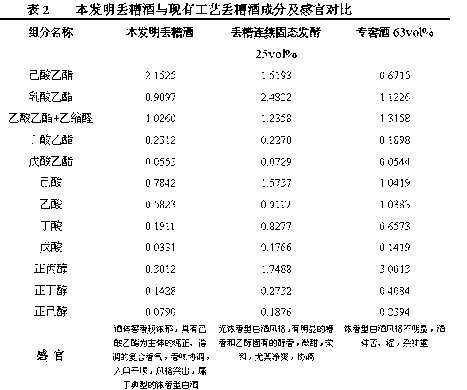

A technology of Luzhou-flavor liquor and its production method, which is applied in the field of Luzhou-flavor liquor production, and can solve the problem that the aroma and taste substances are not effectively utilized, it is not conducive to the fermentation of beneficial microorganisms for winemaking, and it is impossible to carry out high-quality grains "continued grains fermentation, etc. problems, achieve the effect of reducing the secondary fermentation process, highlighting the style, and coordinating the fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1: a kind of method for producing Luzhou-flavor liquor that can reduce residues from extrusion in non-hot season, its technological process is as follows:

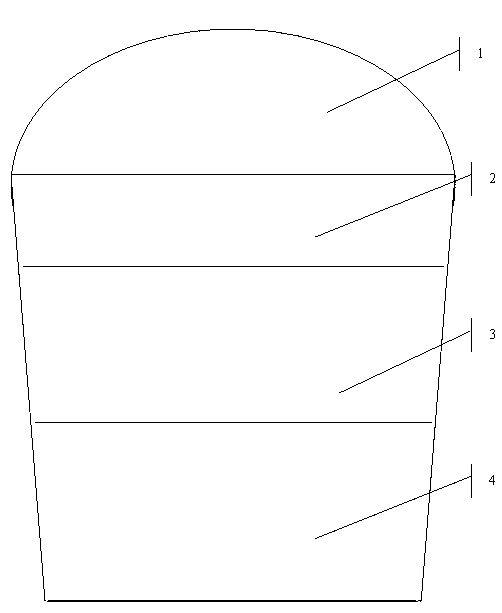

[0076] 1. The process of peeling and extracting bad

[0077] Completely peel off the cellar that has passed a fermentation period, quickly take out the surface dregs 1 in units of one retort, move it to the stall after dripping all the yellow water, and then take out the upper dregs 2, middle dregs 3 and bottom dregs 4 from top to bottom ; The bad grains of each retort are stacked in order according to the order of taking them out, and the piles are separated from each other without mixing;

[0078] 2. Blending and mixing process

[0079] The middle layer grain 3 after being fermented out of cellar, through the grain raw material of pretreatment, slaking chaff shell, according to every retort amount middle layer bad grain: used dry grain raw material weight: the weight of ripe chaff husk, be the weight r...

Embodiment 2

[0097] Embodiment 2: Another kind of Luzhou-flavor type liquor production method that can reduce the residue of extrusion in non-hot season, its technological process is as follows:

[0098] 1. The process of peeling and extracting bad

[0099] Completely peel off the cellar that has passed through a fermentation period, quickly take out the surface dregs and move them to the stall to drain the yellow water in units of one retort, and then take out the upper dregs, middle dregs and bottom dregs from top to bottom; The measured bad grains are stacked in an orderly manner according to the order of taking them out, and the piles are separated from each other without mixing;

[0100] 2. Blending and mixing process

[0101] By fermenting the middle grain after cellar, through the pretreated grain raw material, ripened bran husk, according to every retort amount middle grain: used dry grain raw material weight: the weight of ripe chaff husk, be the weight ratio of 9:1:0.5. well mi...

Embodiment 3

[0119] Embodiment 3: a kind of Luzhou-flavor type liquor production method that can reduce the residue of squeezed grains in hot season, its technical process is as follows:

[0120] 1. The process of peeling and extracting bad

[0121] Completely peel off the cellar that has passed through a fermentation period, quickly take out the surface dregs and move them to the stall to drain the yellow water in units of one retort, and then take out the upper dregs, middle dregs and bottom dregs from top to bottom; The measured grains are stacked in an orderly manner according to the order of taking them out, and the piles are separated from each other without mixing;

[0122] 2. Blending and mixing process

[0123] By fermenting the middle grain after cellar, through the pretreated grain raw material, ripened bran husk, according to every retort amount middle grain: used dry grain raw material weight: the weight of ripe chaff husk, be the weight ratio of 9:1:0.5. well mixed;

[012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com