Formaldehyde-free antibacterial and iron-free finishing liquid and finishing method for shirts

A technology of non-iron finishing and finishing liquid, which is applied in fiber treatment, textiles and papermaking, etc. It can solve the problems of affecting the comfort and health of the wearer, unstable formaldehyde content of garments, and shortening the service life of shirts, so as to improve the freshness and comfort, uniform distribution of electron clouds, and a large degree of conjugation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

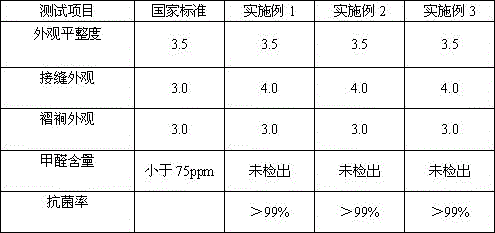

Embodiment 1

[0030] Taking the pure cotton 80 / 2 twill shirt as an example, the steps are as follows:

[0031] (1) Pre-washing: remove the soluble organic and inorganic impurities remaining during shirt production, wash at 40°C, adjust the pH of washing to 4.5-5.5 with citric acid, and wash in two-way rotation at a speed of 25 rpm for 20 minutes;

[0032] (2) Drying: Rotate the pre-washed shirt in both directions at 45°C until dry;

[0033] (3) Finishing liquid treatment: The finishing liquid is atomized and sprayed onto the tumbled shirts through a closed atomization device, so that the liquid-carrying rate of the shirts reaches more than 85%. The components of the finishing liquid in this embodiment include by mass percentage: 45% cross-linking agent, 3% zinc acetate, 10% polyethylene dispersion, 5% silver ion antibacterial agent, and the balance is deionized water with an ion content less than 20ppm. The molecular formula of the cross-linking agent is C 23 h 17 N 6 FO (BASF, Germany),...

Embodiment 2

[0044] Taking the pure cotton 80 / 2 twill shirt as an example, the steps are as follows:

[0045] (1) Pre-washing: remove the soluble organic and inorganic impurities remaining during shirt production, wash at a temperature of 50°C, adjust the pH of washing to 4.5 to 5.5 with citric acid, and wash in two directions at a speed of 30 rpm for 25 minutes;

[0046] (2) Drying: Rotate the pre-washed shirt in both directions at 50°C until dry;

[0047] (3) Finishing liquid treatment: The finishing liquid is atomized and sprayed onto the tumbled shirts through a closed atomization device, so that the liquid-carrying rate of the shirts reaches more than 85%. The components of the finishing liquid in this embodiment include by mass percentage: 35% crosslinking agent, 4% ammonium chloride, 8% polyethylene dispersion, 12% silver ion antibacterial agent, and the balance is deionized water with an ion content less than 20ppm. The molecular formula of the crosslinking agent is C 23 h 17 N ...

Embodiment 3

[0058] Taking the pure cotton 80 / 2 twill shirt as an example, the steps are as follows:

[0059] (1) Pre-washing: remove the soluble organic and inorganic impurities remaining in the production of shirts, wash at 40°C, adjust the pH value of washing with citric acid to 4.5-5.5, rotate in both directions, rotate at 10 rpm, and wash for 30 minutes;

[0060] (2) Drying: Rotate the pre-washed shirt in both directions at 60°C until dry;

[0061] (3) Finishing liquid treatment: The finishing liquid is atomized and sprayed onto the tumbled shirts through a closed atomization device, so that the liquid-carrying rate of the shirts reaches more than 85%. The components of the finishing liquid in this embodiment include by mass percentage: 50% crosslinking agent, 5% sodium citrate, 5% polyethylene dispersion, 25% silver ion antibacterial agent, and the balance is deionized water with an ion content less than 20ppm. The molecular formula of the crosslinking agent is C 23 h 17 N 6 FO (B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com