Material mixing method for preparing wolfram carbide particle (WCp)/2024Al composite radiation shield material

A technology of shielding materials and composite radiation, which is applied in the field of mixing materials to improve the uniformity of tungsten carbide particle distribution in aluminum-based composite materials, can solve problems such as uneven dispersion and easy segregation, and achieve simple process, low production cost, Effect of Loss Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

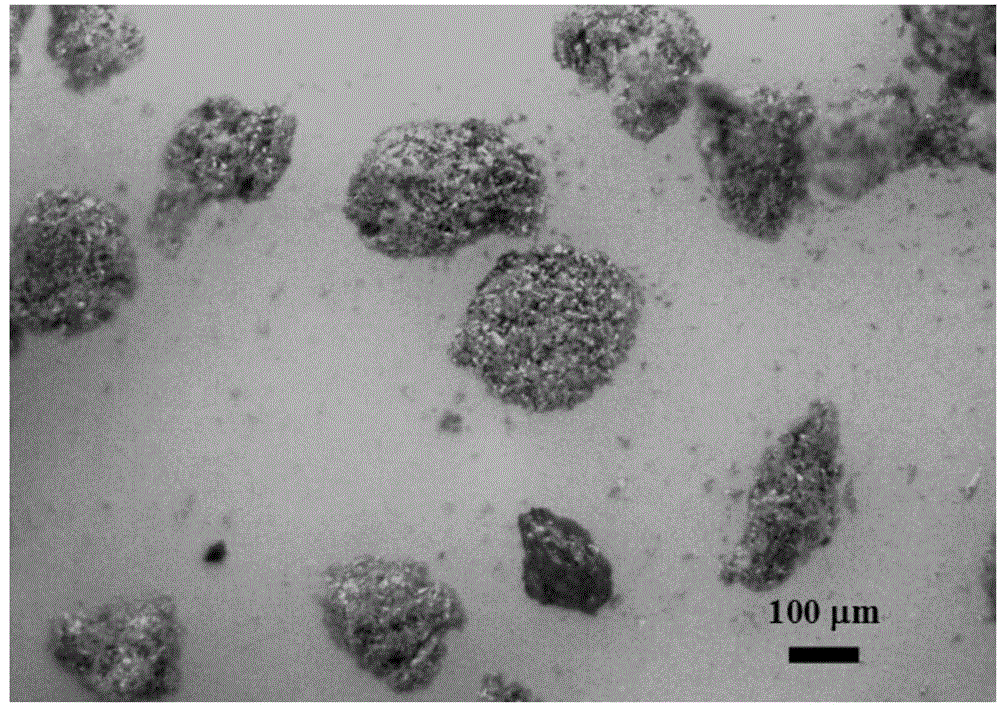

[0050] Weigh 66g of WC powder and 33g of 2024Al powder according to the mass ratio of WC powder: 2024Al powder of 2:1. The WC powder that will take by weighing is poured in the coating pot (diameter is 300mm) on the water chestnut formula coating machine, setting coating machine main frame rotating speed is 1000r / min, is that the PMMA acetone solution of 8% is sprayed in mist form with mass concentration On the surface of WC powder, after observing that the WC powder is basically wet, add 3g of 2024Al powder and mix for 5 minutes. After the 2024Al powder is almost completely coated on the surface of WC particles, scrape off the WC particles attached to the coating pot wall, Spray the PMMA acetone solution on the WC particles again in the form of a mist until the WCp / 2024Al mixed powder is basically wet, then add 3g of 2024Al powder, mix for 5min, and repeat the above process until all the weighed 2024Al powder is added.

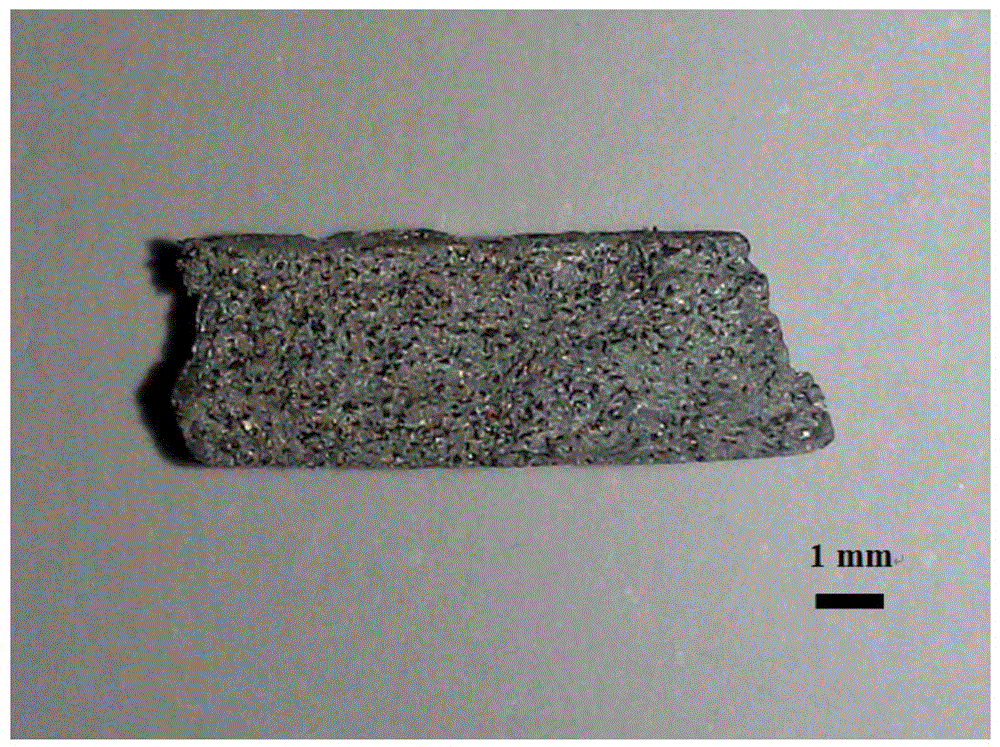

[0051] Transfer the mixed powder to the mold, press 70M...

Embodiment 2

[0058] Weigh 99g of WC powder and 33g of 2024Al powder according to the mass ratio of WC powder: 2024Al powder of 3:1. The WC powder that will take by weighing is poured in the coating pan (diameter is 300mm) of water chestnut formula coating machine, setting coating machine main machine rotating speed is 1200r / min, is that the PMMA acetone solution of 10% is sprayed in mist form with mass concentration On the surface of WC powder, after observing that the WC powder is basically wet, add 2g of 2024Al powder and mix for 5 minutes. After the 2024Al powder is almost completely coated on the surface of WC particles, scrape off the WC particles attached to the coating pot wall, Spray the PMMA acetone solution on the WC particles again in the form of a mist until the WCp / 2024Al mixed powder is basically wet, then add 2g of 2024Al powder, mix for 5min, and repeat the above process until all the weighed 2024Al powder is added.

[0059] Transfer the mixed powder to the mold, press 70MP...

Embodiment 3

[0066] Weigh 66g of WC powder and 33g of 2024Al powder according to the mass ratio of WC powder: 2024Al powder of 2:1. The WC powder that will take by weighing is poured in the coating pan (diameter is 300mm) on the water chestnut formula coating machine, setting coating machine main frame rotating speed is 1000r / min, is that the PMMA acetone solution that mass concentration is 3% is sprayed on On the surface of WC powder, after observing that the WC powder is basically wet, add 3g of 2024Al powder and mix for 5min. Spray the PMMA acetone solution on the WC particles in the form of a mist until the WCp / 2024Al mixed powder is basically wet, then add 3g of 2024Al powder, mix for 5min, and repeat the above process until all the weighed 2024Al powder is added.

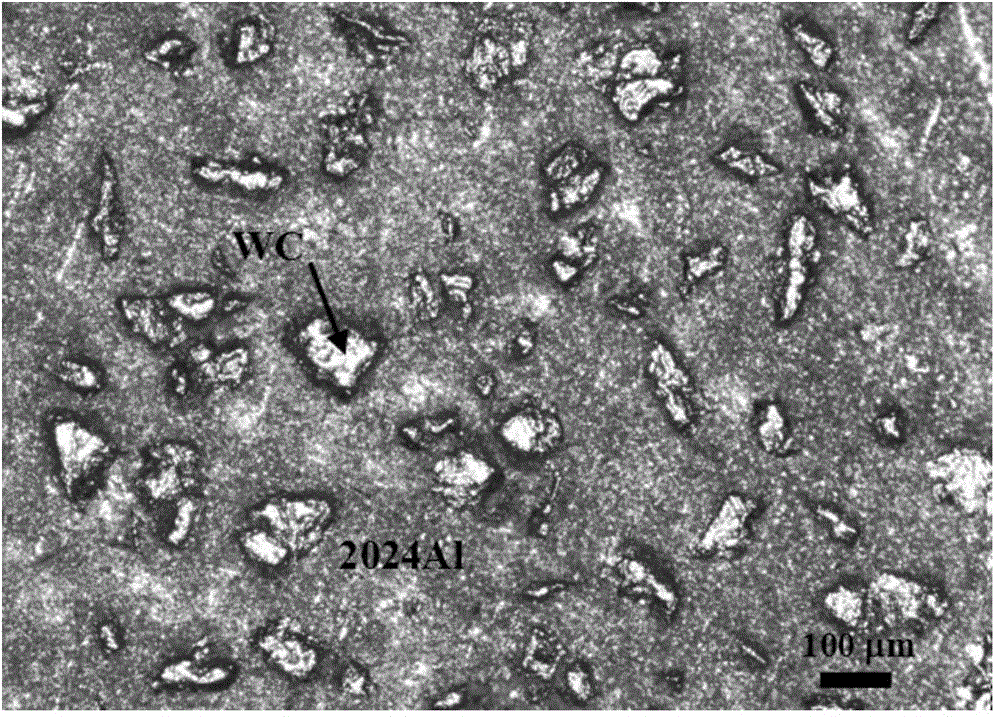

[0067] Transfer the mixed powder to the mold, press 70MPa pressure on the powder metallurgy hydraulic press to form a compact compact with a diameter of 10mm, then grind, polish and observe the microscopic morphology, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com