Manufacturing method and device for fibre laser and electrochemical complex nanosecond pulse deposition

A nanosecond pulse and fiber laser technology, which is applied in the field of fiber laser electrochemical space deposition micro-manufacturing, can solve the problems of poor quality, loose and localized effect of deposition layer materials, and difficult discharge of cathode gas, achieving constant temperature, compact structure, Good processing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

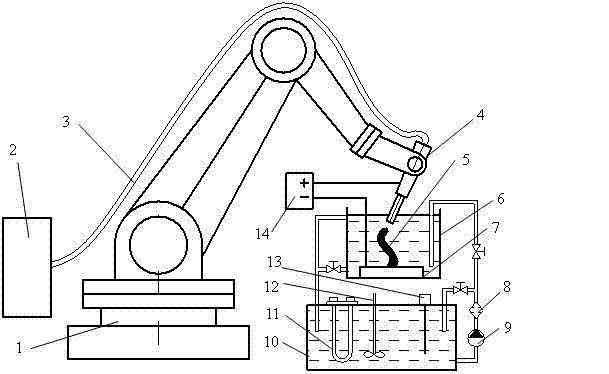

[0021] Combine below figure 1 and figure 2 Describe in detail the specific device details and working conditions proposed by the present invention.

[0022] The device adopted for implementing the manufacturing method of fiber laser and electrochemical composite nanosecond pulse deposition of the present invention includes a three-dimensional laser robot 1, a fiber laser 2, a transmission fiber 3, a laser processing head 4 and an electrodeposition manufacturing system connected in sequence; the three-dimensional laser robot The processing head 4 is wrapped with an insulating jacket 43 on the outside, and the inside includes an optical fiber inner core 45 and an optical fiber cladding 44. The front end of the optical fiber is protected by a glass baffle 41, and also includes an electrodeposited insoluble tool anode 42 made of titanium alloy. Its structure is as follows: figure 2 As shown; the electrodeposition manufacturing system is composed of a deposition liquid tank 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com