Method for preparing gemcitabine hydrochloride lyophilized powder

A technology for gemcitabine hydrochloride and freeze-dried powder injection, which is applied in the field of preparing gemcitabine hydrochloride freeze-dried powder for injection, can solve problems such as poor clarity, and achieve the effects of low drying temperature, low content of related substances, and safe and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

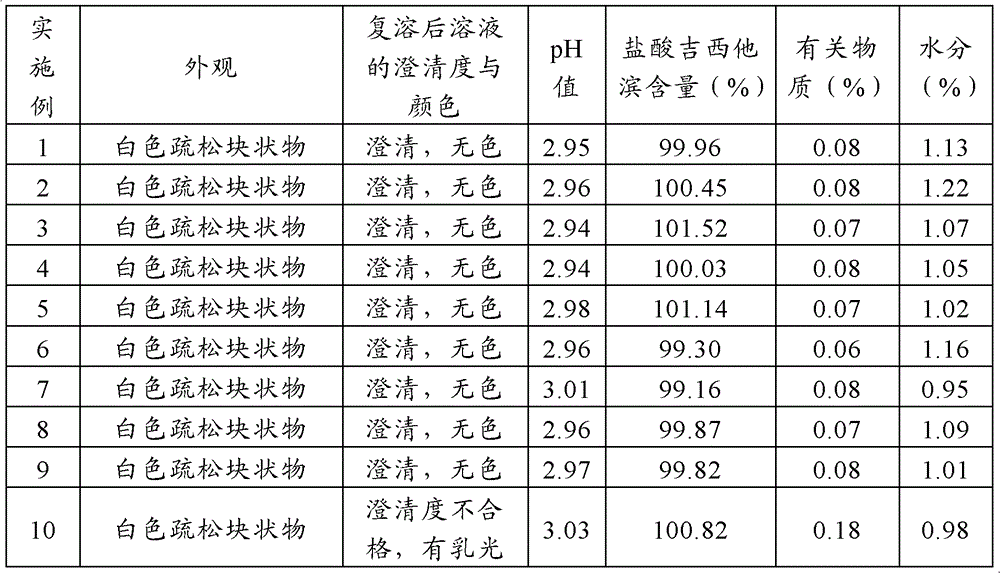

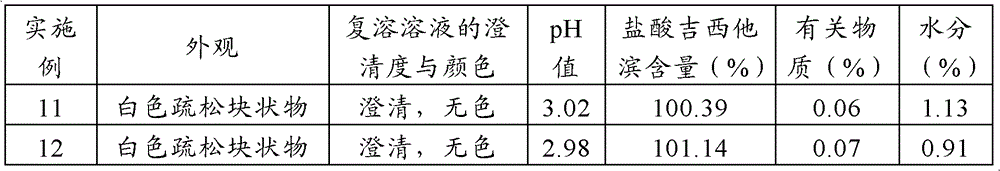

Examples

Embodiment 1

[0036] Preparation: Weigh 228 g of gemcitabine hydrochloride, add 4.5L of water for injection, stir to dissolve, then add 200 g of mannitol and 12.5 g of sodium acetate, stir to dissolve completely, and add water for injection to 5L. Add 2.5g of activated carbon, stir and let stand for 15min, filter, fill at 5mL / bottle, half stopper, and send it to the freeze drying oven.

[0037] Freeze-drying: reduce the temperature of the freeze-drying box to -40°C and keep it warm for 4 hours. Turn on the vacuum pump. After the vacuum degree in the drying box is 20-30Pa, start heating and drying at a rate of 0.15℃ / min to raise the product temperature to -13℃, control the vacuum degree at 15-30Pa, and dry for 15h. Then the temperature is increased at a rate of 1.0°C / min to increase the temperature of the product to 20°C, and the vacuum is controlled to dry at 15-30Pa for 5h. The freeze-dried products are plugged, out of the box, tied with aluminum lid, and packaged and stored after passing th...

Embodiment 2~8

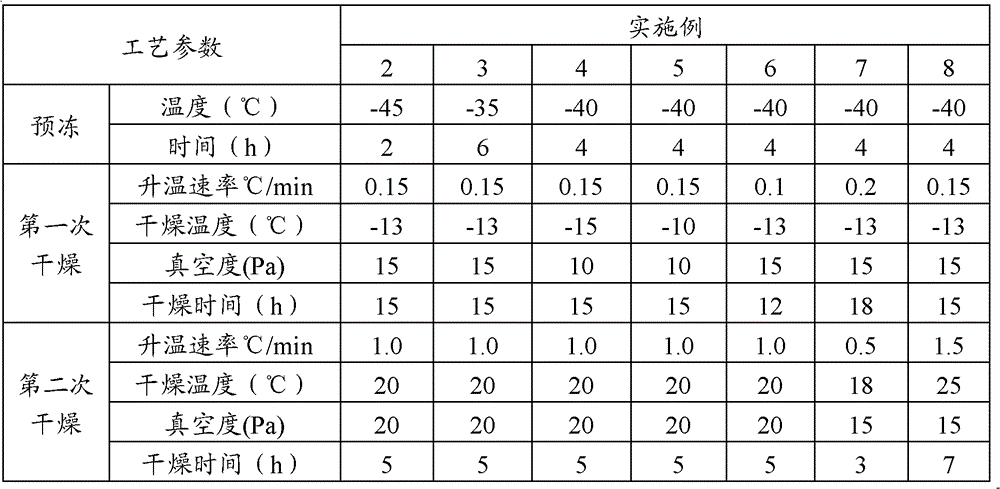

[0039] The liquid preparation process is the same as in Example 1, and the parameters of the freeze-drying process are shown in Table 1.

[0040] Table 1 Examples 2-8 freeze-drying process

[0041]

Embodiment 9

[0043] The liquid preparation process is the same as in Example 1. In the freeze-drying process, the pre-freezing method adopts the quick-freezing method, that is, the temperature of the freeze-drying box is lowered to -40° C., and then the sample is pre-frozen for 4 hours. The remaining freeze-drying process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com